- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production of electronics

Results for

Production of electronics - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

Perfect fit: Fat remover ASF 560 E for pork belly and loin of pork. Maximum yield with little post-processing. Optimised blade holder profile for exact adaptation to the cross section of the product. Electronically controlled movement along longitudinal profile for exact adjustment to the fat contours. The result: Less fat on the pork belly/loin, less lean meat in the belly/back fat. Advantages Minimal post-processing after the processing workflow Line concept: Perfect integration of the machine in stripping workflows Options: Operating personnel can also remain outside the machine stand Curved blade holder profile for ideal product adaptation Special sub-frames (height adjustment)

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• 2.4 mm up to 6.4 mm Ø alu and copper • Up to 6 mm Ø steel & 5 mm Ø stainless steel • Up to fl ange diameter 11.4 mm • Rivet body lengths above 30 mm • Traction power up to 11,770 N at 6-7 bar air pressure Productivity and savings potential • Up to 40 blind rivets can be processed every minute • No trained personnel required for operation • Can be easily integrated into fully-automatic production systems • Electronic system controls • Intuitive menu guidance via navigation and function keys • Function display • Maintenance display and simple fault diagnosis • Customer-specifi c software modifi cation is possible • Ideal for applications that do not require any process monitoring • Rivet mandrels are disposed of by vacuum system • Spring loaded trigger system as an optional extra available • Can be integrated into the system or operated independently • Interface for external memory programmable control system (SPS) can be realised via the GESIPA® interface

Request for a quote

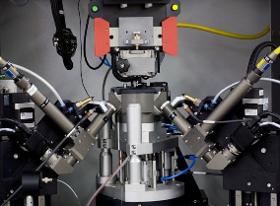

NANOSYSTEC GMBH

Germany

The NanoWeld stations provide the ideal platform for the development and production of opto-electronic components, like singleand multi-channel transmitters and receivers. The station works with exchangeable trays and grippers accepting all device housing types and lenses, optical fibers or receptacles to be aligned and attached. Cycle times for the rapid mass production of TOSA type assemblies reach less than 25 seconds while it takes several minutes for complex devices.All components and subassemblies to build the NanoWeld station are of highest quality and performance. Even customized systems start from a common platform which minimizes development time and cost. By using device-specific trays and grippers, the time to change between different batch processes or device types is reduced to the minimum. Loading and unloading of these trays is performed on a separate loading station outside of the automated NanoWeld. The automated alignment starts from a known reference position.

Request for a quote

KLN ULTRASCHALL AG

Germany

The KLN BATCH-INLINE cleaning system is based on many years of experience with Inline Cleaning systems for the electronics production and unites, for the first time, the technological advantages of Inline cleaning with low space requirement of a Batch system. By far, most of the Inline cleaning systems in Germany for the large-scale production “Automotives” and “alternative energy” come from company KLN. This system was developed to make the efficient Inline cleaning technology available now also for customers with smaller budgets and throughputs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Production of electronics - Import exportNumber of results

4 ProductsCountries

Company type