- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic drives

Results for

Pneumatic drives - Import export

GEPPERT RÜHRTECHNIK GMBH

Germany

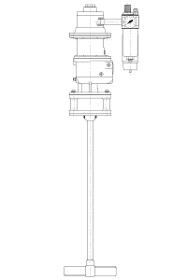

CRP-M - Pneumatic tote tank mixer for stainless IBCs The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

CRP-E - Pneumatic tote tank mixer for plastic IBCs CRP-E Pneumatic tote tank mixer for plastic IBCs The tote tank mixers CRP-E are equipped with a pneumatic drive. It has been especially designed for plastic IBCs with filling openings of at least 150 mm and volumes from 600 l up to 1,200 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator Folding propellers that fit through the filling opening DN 150 mm are used for geared agitators. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The tote tank mixers CRP-E are equipped with a pneumatic drive. It has been especially designed for plastic IBCs with filling openings of at least 150 mm and volumes from 600 l up to 1,200 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator. Folding propellers that fit through the filling opening DN 150 mm are used for geared agitators. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are balanced for concentric run after assembly. Explosion-proof mixers are also feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNIFLEX-HYDRAULIK GMBH

Germany

Guillotine for industrial hoses •up to 2” (max. OD: 75 mm) •Pneumatic Drive •L x W x H (mm) : 1810 x 325 x 800

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Efficient positioning, assembly and handling of workpieces are key components in many manufacturing companies to meet growing cost pressures. Replacing pneumatic cylinders with electric linear drives can save up to 90 % of energy consumption. In addition, there are numerous advantages in motion control. IAI has the world's largest portfolio of electric actuators with 24 or 230 volt stepper or servo motors. The electric cylinders perform linear, rotary or gripping movements and are characterised by the uniquely compact design including motor and encoder as well the high quality. In addition to the standard version, electric cylinders are also available for cleanrooms and as IP-protected models for dusty or wet production environments.

Request for a quote

KLN ULTRASCHALL AG

Germany

Basically the TOOLMASTER versions vary by their tool design, their size of useable surface and the degree of automation. All versions are suitable for high temperatures and optionally equipped with fire protection engineering, which quickly separates the tool in case of energy drop or timeout. KLN also manufactures special machines adapted to your individual requirements. TOOLMASTER "Basic" as well as type HE 50/30 are standard machines. The versions "Advance", "Semi-Automatic" and "Automatic" are made with tools in sandwich design. This makes possible the handling of upper tool, hot plate element and lower tool as a compact unit. They are designed particularly for quick and frequent production changes. The HE/SA has a horizontal concept with servo-drive technology for quick and precise movements. The TOOLMASTER CC has been developed for applications with two welding tasks in one cycle. Almost all machine versions can be provided with pneumatic or servo-motor drives.

Request for a quoteResults for

Pneumatic drives - Import exportNumber of results

9 ProductsCountries

Company type