- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- plastics - machines and material for industry

Results for

Plastics - machines and material for industry - Import export

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Integratable in the production line, only the inspection windows of the bags will be perforated. The neighbor areas of the inspection windows are left unperforated. The perforation holes are melted down with hot needle rollers of steel at high temperatures.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

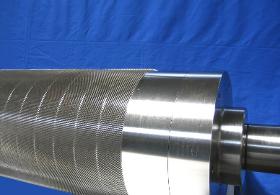

A ready-to-install needle roller on its own shaft or segments to place on the roller for different applications - more details on our homepage! The construction of complete needle or perforation rollers depends on the intended use. Please describe your requirements exactly! Perforation rollers usually consist of individual segments, which are mounted on a shaft or a tube. The mass inertia can be reduced by bearings between the shaft and the tube. In case of driven shafts, the segments can be firmly anchored to this. A sketch of the installation situation with a short description of the requirements helps us to find the optimal solution!

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Our modular system provides cost-effective, simple and flexible integration of a perforation in your system. Working widths up to approx. 4 meters can be realized, optionally with manual or pneumatic delivery of the perforation roller. This gives you an exact setting of the perforation depth. A quick shift of one to another machine is also possible!

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

to reduce the mass of the spiked roller, for example, in and out pivoting perforation roller for partial perforation

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

ProTec offers complete production systems for manufacturing long-fiber reinforced thermoplastics (LFT) in pellet form and as UD tapes (unidirectionally reinforced tapes) as well as impregnated fiber strands and profiles. The system works extremely flexibly and is designed for variable formulations and high throughputs at a production speed of 50 m/min. We deliver an LFT system design customized to meet the respective customer requirements, all from an single source – from material development, to testing and commissioning on location at the customer‘s premises.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The BB 60 is a combination of two components: the blanketing unit BU 0.6 and the day bin DB 60. The 60 litre stainless steel bin is installed on a mobile frame and is equipped with a sight glass and suction box. Blanketing keeps granules dry for several days, resulting in more reliable production and energy savings because of low compressed air consumption. In addition, the bin contributes to a safer and cleaner workplace as material spillage from open 25kg bags is eliminated.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

motan’s material selection stations assure that every desired connection of a material to a processing machine in your production process can be made quickly and reliably without contamination. Fixed pipe connections throughout the whole production process until the next material change ensures maximum security. METROLINK: the most advanced fully automatic material selection and distribution system.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

With the METRO G/F/R material loaders, large quantities of granulate, dusty regrind and flakes can be conveyed automatically to the hopper of a processing machine, drying bin or day bin. Filters with sophisticated cleaning technology and large outlet flaps guarantee trouble-free operation. Via the hinged lid, free from vacuum and material hoses, the loaders can be quickly and easily cleaned during material changes.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

motan’s material coupling stations assure that every desired connection of a material to a processing machine in your production process can be made quickly and reliably without contamination. METROCONNECT U: a manually operated un-coded coupling table. METROCONNECT C: a manually operated coded coupling table utilising state-of-the-art wireless RFID technology.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The three-phase conveying station can be used for a wide range of central conveying applications with a large choice of blower sizes. The three-phase blower is low-noise and maintenance-free. The station is available with a blower protection filter or optionally a cyclone dust filter with collection bin. The integrated VAC swift control is equipped with a 7“colour display which can operate up to 8 METRO swift HOS material loaders and up to 8 purging valves.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Efficient, accurate material drying is a crucial element in the processing of engineering plastics to ensure impeccable product quality. The fully-insulated LUXOR CA S compressed air dryers provide a cost-effective solution for highly efficient continuous drying of all types of plastic granulate with material throughputs up to 25 kg/h. Dryers can be mounted directly on the throat of the processing machine or on an adjacent support frame.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

SPECTROFLEX G is ideally suited for dosing powders, pellets, regrind, granulates, flakes and fibers in continuous processes. motan's unique interchangeable system provides two huge advantages over common dosing units. Firstly, the user can swap the quick exchange modules in less than one minute easily without any tools. Furthermore, the single and twin screw exchange modules are also interchangeable, allowing the user to configure the feeder for nearly any type of material in a matter of minutes.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

METRO SG HOS system material loaders can automate important areas of the production process cost-effectively and efficiently. Virgin and regrind material is conveyed quickly and cleanly to the hopper of a processing machine, a drying bin or a dosing and mixing unit. Material is delivered exactly when needed keeping machines running and avoiding costly downtime. Material wastage is eliminated and the work-space is kept clean and safe.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

motan is a world leading supplier of complex centralised material feed systems. Each system is designed to suit the customer by taking into account individual factors such as throughput, materials types, and plant layout. A wide selection of loaders with a variety of conveying options, controls, blowers, and filter techniques allow the creation of the optimum system for the customer’s facility.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The COMPACT swift dryers are designed with flexibility in mind. They offer an integrated solution, combining the drying and conveying of the raw material in one unit. The dryers are available in two versions and are each equipped with one drying bin of the size 80 or 150 litres and up to 2 hopper loaders with a capacity of 4 litres each. The COMPACT swift A dryer is provided with advanced functions such as dew point control and dry air conveying function with line purging. Thanks to a modern 7-inch colour display with touch screen, all conveying and drying functions can be shown and monitored in a user-friendly way. 16 user languages can easily be selected.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The new LUXOR swift 250 dry air generator offers the ideal price-performance ratio for standard applications in the drying of granulate. The LUXOR swift 250 has a dry air capacity of 250 m³/h. The dry air generator can either be operated with a single drying bin or combined with multiple preconfigured drying bins in your plant. The drying bins are available from 100l to 900l sizes. This gives you the maximum possible flexibility and an uninterrupted production flow. For more energy efficient drying, additional functions such as dew point control or return air cooling can be added. Versatile use Different drying bin sizes for different applications Thanks to motan’s automatic air regulation the drying process can be optimized. Different sizes of drying bins with integrated heating allow a wide range of applications with proven motan drying technology.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Combining additives with the virgin material at the processing machine requires excellent mixing quality and consistently accurate dosing. These requirements can be achieved and exceeded with the volumetric MINICOLOR swift V dosing and mixing unit. The units are mounted at the feed throat of the plastics processing machine and are space-saving.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MOTAN-COLORTRONIC GMBH

Germany

METRO G is the most comprehensive and flexible material loader range on the market. It combines the best of two established material loader ranges – colortronic and motan. Whether simple or highly complex, METRO G’s modular building block system will provide you with an individual solution tailored to your needs.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

ULTRABLEND medical is a gravimetric batch dosing and mixing station for plastic granules, additives, and regrind. It has been specially designed for pharmaceutical and medical technology applications. The high dosing accuracy and consistency of the ULTRABLEND improves end product quality and saves money by using less additives and reducing scrap. The ULTRABLEND is suitable for direct mounting on small injection moulding machines and extruders. All components are accurately dosed and weighed one after another into a weigh hopper. They are then passed to the mixing chamber where they are homogeneously mixed.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

The METRO SG HES range of single-phase material loaders enable processors to automate a key area of the production process cost effectively, bringing significant benefits for process management. Plastic granulate is conveyed quickly and cleanly to a processing machine hopper, a drying bin or a day bin as needed. The material loader is equipped with its own control, so that it recognizes when material is needed and automatically starts conveying. This keeps machines running and avoids costly downtime while eliminating material wastage, keeping the workspace clean and safe. The METRO SG HES range can handle throughputs of 15 to 200 kg/h.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

For many dosing applications, it is necessary to homogeneously mix different materials of varying bulk densities and flow characteristics. The mixer module 2l is designed for mounting under a dosing unit, where it will mechanically mix, for example a powder additive with virgin material. Further possible uses: Homogenous mixing of virgin material and regrind or with masterbatch or additives. motan has 3 versions available: — Mixer module 2l-MB for MINIBLEND V — Mixer module 2l-MC for MINICOLOR V / G — Mixer module 2l-Uni for universal applications and third-party products

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

In the plastics compounding and manufacturing process there are many powders (all with different flow properties) which require handling. For the vacuum conveying of both free-flowing and non-free-flowing powders, motan has a solution. The METRO P series of hopper loaders are available in two versions and guarantee reliable and dust-free conveying. The METRO PC system loaders are designed to be integrated into centralised motan conveying systems. The METRO PB single loaders are designed to be used as a “stand-alone” solution. From the material source right through to the point of processing, motan offers the ideal solution for your powder handling requirements.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Metal separators from motan can be installed at various locations in a production and for multiple applications. The metal separators prevent damage to your processing machine, tooling and end-products

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Cost-effective and efficient material conveying can be realized with METRO swift HOS material loaders. This improves the overall process management of your system. The plastic granules are transported quickly and cleanly into hoppers, drying bin or other dosing and mixing units and fed to the machine as required. This eliminates material wastage and keeps the work-space clean and safe.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

With the METROFLOW gravimetric material loader, plastic processors can automate important areas of the production process cost-effectively and efficiently. The METROFLOW weighs every single load and evaluates the results, with a guaranteed precision of <1%. This improves the entire material management process and allows for full traceability. The material loaders come in 6, 10 and 30 liter volumes. The METROFLOW series is part of the motan range of products and systems for all stages of management, conditioning and preparation of plastic granules. The design quality, plus the engineering, ensures high performance and reliable operation.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

SPECTROPLUS is a gravimetric & volumetric synchronous dosing & mixing unit for diverse materials – from granules, regrind or powders to liquids and flakes. Due to the modular design of the SPECTROPLUS with only one frame size and up to 8 dosing module positions, it is one of the most flexible overall systems in the motan product world. In addition to the gravimetric and volumetric version, the SPECTROPLUS can also be combined (gravimetric and volumetric dosing modules in combination). This makes it ideal for individual applications and also complex end products. motan's SPECTROFLEX units can easily be added to the SPECTROPLUS.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Injection moulders for making very small parts are faced with the unique challenge of being able to dry just the right amount of material for their process. Operating in extremely critical production conditions, these smaller throughputs can present considerable problems. It is important to scale the drying to the size of the moulding machine. The LUXOR CA S 0.75 to 5 range of compressed air micro dryers is specifically designed for small material throughputs. The range comprises of a modular line of correctly sized drying equipment to help moulders meet the small tolerances without waste or contamination. These small dryers take factory supplied compressed air which is expanded to atmospheric pressure. This produces dry process air with a very low dew-point which is then heated to the required drying temperature. No desiccant is required.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

LUXOR A series dryers with ETA-process® and ETA plus® energy saving technology are specifically designed for supplying dried plastic granulate for many different plastics processing applications. They have either two or three fully insulated stationary desiccant beds with separate process and regeneration blowers which provide consistently low dew-point air to the process, while reducing energy consumption. The advanced LUXOR A series consists of ten models with drying capacities from 80 to 2400 m3/h. Each advanced system dryer can be flexibly combined with all LUXORBIN A drying bins from 15 to 2400 litres. In addition, motan offers a range of extra-large drying bins with volumes from 3,000 to 13,000 litres. These are also available with gas heating. All motan system drying bins are made of stainless steel, are completely insulated, and have individual heating as well as temperature control.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

LUXOR S dryers operate at maximum efficiency and with minimum operating maintenance. The opportunity to have multiple material bins connected to one dry air generator provides our customers with maximum flexibility and no interruption to production. Drying can continue while material is changed in any one bin, minimising loss of valuable production time during material changes. The compact LUXOR S series consists of five models with drying capacities from 40 to 160 m3/h. Each dry air generator can be flexibly combined with a combination of drying bins ranging in size from 15 to 600 litres.

Request for a quoteResults for

Plastics - machines and material for industry - Import exportNumber of results

41 ProductsCountries

Company type