- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- speed steels

Results for

Speed steels - Import export

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

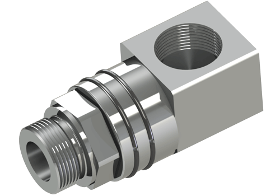

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") PRESSURE MAXIMUM Steel 42CrMo4 315 bar DN 32 (1 1/4") DN 40 (1 1/2") 350 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1") Stainless steel 100 bar DN 32 (1 1/4") DN 40 (1 1/2") 160 bar DN 8 (1/4") DN 10 (3/8") DN 15 (1/2") DN 20 (3/4") DN 25 (1")

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

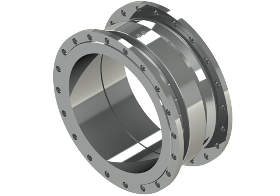

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 16 bar DN 350 DN 400 DN 500 DN 600 DN 700 40 bar DN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") Stainless steel 6 bar DN 350 DN 400 DN 500 DN 600 DN 700 16 bar DN 125 (5") DN 200 (8") DN 250 (10") DN 300 (12") SIZEDN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") DN 350 DN 400 DN 500 DN 600 DN 700

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

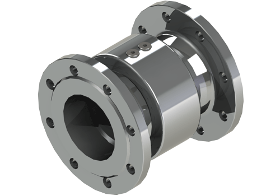

steel (42CrMo4) or stainless steel (1.4571) PTFECompoundseal builtin ball guiding tracks similar to ball bearings swiveling, rotating movements with low speed PRESSURE MAXIMUM Steel 42CrMo4 100 bar DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") 250 bar DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") 350 bar DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") Stainless steel 40 bar DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12") 100 bar DN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") SIZEDN 20 (3/4") DN 25 (1") DN 32 (1 1/4") DN 40 (1 1/2") DN 50 (2") DN 65 (2 1/2") DN 80 (3") DN 100 (4") DN 125 (5") DN 150 (6") DN 200 (8") DN 250 (10") DN 300 (12")

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Working range Sets speed rivets up to Ø 4.8 mm aluminium and Ø 4.0 mm steel. Suitable for speed rivets with a mandrel length between 483 mm and 510 mm. Further lengths available on request. Technical data Traction power: 3,500 N Stroke: 26 mm Operating pressure: 5-7 bar Air hose connection: 6 mm Ø (1/4“) Weight: 1.8 kg Equipment Spreader nosepiece in working position Tag on device head Rubber foot Advantages • Quick setting process, fast rates • Safe working through disposable mandrel and optional automatic switchoff • Ergonomic handling for fatigue-free work • Light and compact design • Modular construction based on the TAURUS® design • Softgrip • Tool-free conversion

Request for a quote

SFS GROUP GERMANY GMBH

Germany

AccuBird® – Production • Developed and produced in Germany since 1992 by the inventor of the battery blind rivet setting tool Reliability • Electronic control • No mechanical switching components • Electronic temperature and overload protection • High reliability through low loss power transmission via a highly effi cient ball screw drive Freedom Cablefree tool for fl exible operation in installation jobs and industry production High performance • 10.000 N setting force • High pulling force for safe setting of blind rivets up to 5 mm diameter in all materials • High yield per battery charge • Large 20 mm stroke Versatility Blind rivets up to 5 mm Ø all materials. BULB-TITE® blind rivets 4 mm, 5,2 mm and 6,3 mm Ø alu and steel High speed • High speed of operation through automatic resetting of the jaw mechanism immediately after each setting process With Li-Ion energy • Choice of 2.0 Ah and 4.0 Ah Li-Ion batteries

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

COD Sinter-HIP furnaces combine the dewaxing, vacuum-sintering and subsequent isostatic densification under pressure gas up to 100 bar of sinter parts made of hard metals or ceramics. COD furnaces optimize all the necessary process functions and combine them in one production equipment and process cycle in an optimal, fully automatic and reproducible manner. Applications: Vacuum- and pressure sintering of hard metal products, PM-high-speed steels and ceramics. Benefit for users: • Low operating costs due to low power and cooling water consumption • High product quality due to excellent temperature homogeneity in vacuum, during pressure gas injection and pressure sintering. • Rapid startup at user's site and productivity "from day one" due to complete pre-assembly and fully hot shop-test and TÜV-acceptance in the factory • Service and maintenance friendly design, high up-time

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Speed steels - Import exportNumber of results

6 ProductsCountries

Company type