- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- slides

Results for

Slides - Import export

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

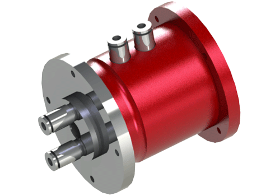

segment design low weight self supportingno additional support necessary sealing PFTECompound good sliding properties low stickslip effect PRESSURE MAXIMUM 9,0 bar air vacuum TEMPERATURE MAXIMUM 90 °C air

Request for a quote

HAAG + ZEISSLER MASCHINENELEMENTE GMBH

Germany

segment design low weight self supportingno additional support necessary sealing PFTECompound good sliding properties low stickslip effect PRESSURE MAXIMUM 9,0 bar air vacuum TEMPERATURE MAXIMUM 90 °C air

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

with long clamping lever max. clamping force 50 kN max. clamping stroke 9.5 mm max. 500 bar, as per data sheet B1.8241

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

with swivel contact bolt max. clamping force 50 kN max. clamping stroke 9.5 mm max. 500 bar, as per data sheet B1.8241

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

with long clamping lever max. clamping force 32 kN max. clamping stroke 8 mm max. 500 bar, as per data sheet B1.8241

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

with swivel contact bolt max. clamping force 32 kN max. clamping stroke 8 mm max. 500 bar, as per data sheet B1.8241

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

with long clamping lever max. clamping force 20 kN max. clamping stroke 7 mm max. 500 bar, as per data sheet B1.8241

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

with swivel contact bolt max. clamping force 20 kN max. clamping stroke 7 mm max. 500 bar, as per data sheet B1.8241

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

compact design max. clamping force 10 kN max. clamping stroke 5.5 mm max. 350 bar, as per data sheet B1.8242

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

RoboCylinder slide table actuators combine high load capacity with very good guiding accuracy. The compact design offers extra stability and enables use even in confined spaces. They are suitable for precise assembly applications, for positioning or for pushing movements of horizontal payloads up to 30 kg and vertical payloads up to 24 kg. The slide tables are provided with fitting holes for changing workpieces. The linear drives are available either as directly driven compact slides with motor in extension of the longitudinal axis as well as shorter versions in which motor and axis are parallel to each other.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

Space-saving electric mini slide table actuators from IAI are used as positioning systems in many manufacturing companies. They are suitable for lifting, lowering, pressing and clamping workpieces as well as for horizontal movements and many other assembly devices. The mini slide table types are available in narrow, wide or flat design. The built-in guide eliminates the need for an external one, which saves assembly space. The latest developments are the miniature slide table types of the RCA2 series with 24V servo motor or the RCS2 series with 230V servo motor.

Request for a quote

DSMART GMBH

Germany

All our slide tin container can be customized with your artwork and idea shapes. Normal shapes are: Oval, Rectangular, Round, Square, Octagonal, Heart and so on. Artwork Format: AI, PDF, EPS, CDR, PSD Printing: Offset printing(CMYK or PMS) Glossy or matt finish outside Natural tin silver or gold varnish inside Metallic effect available Accessories options: Sponge/foam/EVA insert Transparent PET bed/cardboard bed/paper band Velvet trays, locks, handles Decoration options: 3D embossing Spot glossy/matt finish Crackle varnish, pearl varnish Leather effect PVC&PET clear window Material: First grade tinplate, 0.21/0.23/0.25/0.28mm thickness for your choice Usage: for gifts, food, candy, confections, tea, cigarette, tobacco , candle, Christmas, cosmetic etc. Certification: FDA, EN71, SGS

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

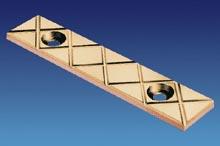

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

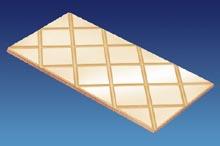

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

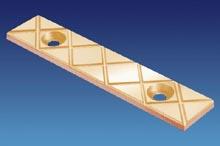

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The products to be recorded can be fed on multiple tracks into a LED camera system, which individually measures and then weighs them at a weighing station. Based on the captured data, the highest yield and minimal give-away is guaranteed during slicing of pieces/chunks and slices. Advantages Open design, simple handling High fault tolerance Excellent detection of products with extremely fluctuating color contrasts Precise measurement even in extraneous light The laser scanner is available in various sizes to fit your product.

Request for a quoteResults for

Slides - Import exportNumber of results

20 ProductsCountries

Company type