- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic machines

Results for

Automatic machines - Import export

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

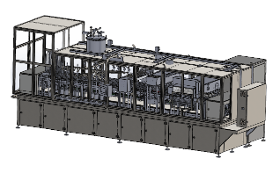

The 200A is linear filling solutions for high and fast production needs. This heavy beast is designed to fulfill heavy-duty needs for big factories and production lines up to 24,000 unit/hour. The machines can be adjusted according to the need of the customer and may serve liquid, paste and molasses in all size ranges.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The smart solution: Fully-automatic defatting machine ASD 460 enables removal of fat layers from loins and cutlets in predefined strengths. Advantages Fully-automatic recognition of the fat strength using Weber camera technology, with programmable controlled movementalong longitudinal profile Continuous work process Sensor-controlled electronic spring for perfect pressure application Uniform fat layers Considerable minimisation of reworking (trimming) Back bacon instead of small trimming cuts Clearly improved product image for cooking after slicing Product-specific blade holders Combinable with pre-installed derinder Options: Special Weber transport rollers Product-specific blade holders Product-specific pressure devices for products withand without bones Fixed or adjustable guide plates for supply and output belts

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

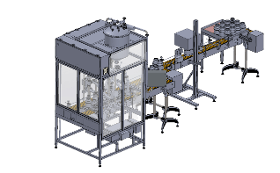

Challenger 200B is semi automatic linear system It’s designed for filling liquid or pasty products in plastic jar With five work stations: Adding jar on conveyor manually, filling, adding covers on jar manually, sealing cover (induction seal), Exiting.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

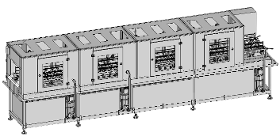

This linear fully automatic machines ensures that boxes used for transportation and storage of diary products are washed and sterilized

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• 2.4 mm up to 6.4 mm Ø alu and copper • Up to 6 mm Ø steel & 5 mm Ø stainless steel • Up to fl ange diameter 11.4 mm • Rivet body lengths above 30 mm • Traction power up to 11,770 N at 6-7 bar air pressure Productivity and savings potential • Up to 40 blind rivets can be processed every minute • No trained personnel required for operation • Can be easily integrated into fully-automatic production systems • Electronic system controls • Intuitive menu guidance via navigation and function keys • Function display • Maintenance display and simple fault diagnosis • Customer-specifi c software modifi cation is possible • Ideal for applications that do not require any process monitoring • Rivet mandrels are disposed of by vacuum system • Spring loaded trigger system as an optional extra available • Can be integrated into the system or operated independently • Interface for external memory programmable control system (SPS) can be realised via the GESIPA® interface

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• Blind rivet sizes from 4.8 mm to 8.0 mm Ø all materials • Rivet body lengths up to 35 mm • Setting head diameter up to 19 mm • Mandrel up to 5.5 mm Ø • Traction power up to 20,000 N at 5 bar air pressure • Conveyor pot filling level display • Operating pressure: 5 bar • Vibration-dampened pressure intensifier attachment • Multiple monitoring of the blind rivet pistol by means of sensors • Industrial control with an 8“ colour display • Conveyor distances of up to 25m are possible when used in fully-automatic production systems • Maintenance display, simple fault diagnosis • Customer-specific software modification is possible • Ideal for applications that do not require any process monitoring • Rivet mandrels are disposed of via a vacuum system • Surface contact trigger optional available • Can be integrated into the system or operated independently • Interface for external memory-programmable control system (SPS) can be realised via the GESIPA®- Interface

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• 2.4 mm up to 6.4 mm Ø alu and copper • Up to 6 mm Ø steel & 5 mm Ø stainless steel • Up to fl ange diameter 11.4 mm • Rivet body lengths above 30 mm • Traction power up to 11,770 N (6-7 bar air pressure) • Cost effective from an annual quantity of around 500.000 blind rivets (related to the german market) • Up to 50 % time and costs savings compared to standard blind rivet devices • Rivet pistol has a large action radius • No trained personnel required for operation • Can be easily integrated into fully-automatic production systems • Up to 40 blind rivets can be processed every minute • Electronic system controls • Maintenance display & simple fault diagnosis • Customer-specifi c software modifi cation is possible • Rivet mandrels are disposed of by vacuum system • Optional Spring loaded trigger system • Interface for external memory programmable control system (SPS) can be realised via GESIPA® interface

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PAE range is an innovative new generation of pallet labellers that can label pallets on up to three sides with either pneumatic and/or electric traversing axles. The labels are printed with individual data in real time immediately before dispensing. The series is designed to integrate thermal transfer printing modules from different manufacturers. Automatic height adjustments are available as an option in order to Application heights on the pallet to start up. The complete traceability of products is essential nowadays, which is why interest in intelligent pallet labelling processes is so high. The system can handle label formats up to DIN A4 format, enabling product labelling according to the global GS1 standards.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The semi-automatic labeling machine TNC-R was developed for the all-round labeling of tubes. Small batches can be labeled quickly and precisely with the labeller. The tubes are placed manually in the labeling system. As soon as the 2-hand operation is activated, the automated labeling process starts. The product is rotated and shifted, then the wrap-around label is applied exactly to the product. A printing unit can be integrated for individual labeling of the tubes. You can easily print the labels yourself inline. The integration of a printing unit is suitable, for example, for laboratory tubes or sample vessels that have to be provided with individual data.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The system is used for labelling or printing flat products such as postcards, flat folding boxes, mailing bags or textile blanks, regardless of the format. The products are fed into the loading chute by the operator and are then destacked layer by layer from below and fed past the labeling or printing or inspection unit. The finished products are then collected in an exit chute or a collection box. This system was developed for a capacity range of up to 100 products/min. For processing higher numbers of products/min, the HSF model series is available which, in addition to a longer conveying distance for setting up different stations also provides the option of a product ejector to automatically remove NIO products from the process and collect them in a separate collection box. The tool-free adjustment enables the shortest changeover times for batch/product changes.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

25 % productivity increase – Automatic Clipping/Hanging Machine for looped products (sausage, cheese) The FCHL ensures continuous production and therefore an increased output rate. The automatic double-clipper with integrated hanging line efficiently combines four processes in a way which saves on manpower: clipping with simultaneous looping, hanging the loop and positioning (suspension) on the smoke stick. Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Gain in efficiency – sealing and clipping with one machine The TSCA Automatic Sealing/Clipping Machine processes flat film from a roll into a ready-to-fill tube which is securely closed by the integral clipping unit. All commonly used films, coated or uncoated, as well as laminates can be processed. The film rolls used can be up to 3,000 metres long. Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

The all-rounder – fully automatic The automatic double-clippers of the PDC-A line are suitable for all sizes of operations – for mid-size or large production runs. They reliably close all casings. The PDC-A 600 closes fibrous casings up to 65 mm calibre and plastic casings up to 90 mm. Using the PDC-A means that all products – single portions or chains, long sausages, half rings and rings – can be produced efficiently. Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Air-free slack filling – calibres up to 200 mm The ICA is the ideal machine for large calibres and moulded products up to a calibre of 200 mm. Fibrous, collagen and plastic casings can be processed. The innovative iris separator makes the ICA ideal for the production of large volumes like slicer products, moulded ham, even those made of whole muscles. Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Entrance into FCA class – for a range of calibres from 38 to 160 mm and up to 125 cycles per minute in continuous mode The FCA 80 is a robust entry-level machine with simple functions that is easy to operate. With four different spreadings the clipping machine offers maximum flexibility. The automatic double-clipper FCA 80 closes collagen casings up to 80 mm, fibrous casings up to 100 mm and plastic casings up to 160 mm (depending on the material thickness). Subject to technical modifications.

Request for a quote

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Maximum automation – for the 38 – 160 mm calibre range at up to 160 cycles per minute in continuous mode The FCA 160 offers unrivalled versatility combined with highest automation. It closes collagen casings up to 90 mm, fibrous casings up to 120 mm and plastic casings up to 160 mm (depending on the material thickness). Subject to technical modifications.

Request for a quote

DSMART GMBH

Germany

Production Process of laminated printed film roll A: Artwork confirmation B: Printing cylinders making C: Prepare raw material accordingly D: Printing E: Lamination F: Slitting or folding G: Bag making/cutting H: Final inspection J: Delivery Other information of laminated printed film roll A: We are specialized in making all kinds of packaging materials, such as food bags, coffee bags, zipper bags, ziplock bags, stand up pouches, black bottom bags, aluminium foil bags, pet food bags, tobacco bags, fruit packaging bags, vegetable packaging bags, paper bags, tin boxes, hole puncher for plastic bags. B: We do printing according to your design artwork, just send us layered design in AI or PDF or PSD format. C: The MOQ is 10,000 pcs, the more the cheaper D: Similar samples are available Disclaimer: All trademarks and pictures shown here are as example of our production capability, they are not for sale, and they are the property of their owners.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Automatic machines - Import exportNumber of results

17 ProductsCountries

Company type