- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- load testing

Results for

Load testing - Import export

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

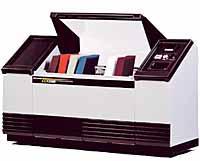

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

Degradation and Heat Sunlight can have adverse affects on materials and components, oftentimes initiating and accelerating the degradation process as it interacts with temperature, moisture and other environmental effects. In addition, it is critical to understand the effects of heat created by sunlight with respect to operational performance, thermal management, noise and dimensional stability. A new product should be tested under solar environmental conditions representative of those locations in which it will exist - anywhere ranging from the heat of the outback in Australia to the frigid climate of arctic areas. Atlas solar simulation systems are custom-designed in both power and size. Having this flexibility, they can be integrated into various types of environmental test chambers whether they be small or walk-in, chambers used in component/ small product testing or drive-in chambers for complete vehicle testing, even up to extra large systems for trains, trucks and aircrafts. Superior Solar Simulation with SolarConstant A key to the success of solar environmental testing is the quality of the solar simulation itself. A close spectral match to natural sunlight is critical for accurate reproduction of test conditions. The Atlas SolarConstant luminaire offers high irradiance efficiency and superior spatial uniformity on the test area. Combined with special Metal Halide Global (MHG) lamps and optical filters, the SolarConstant creates a spectral distribution that closely matches natural sunlight. Its proven modular design makes this unit ideal for large custom-designed solar simulators as well as smaller standardized laboratory test systems. SolarConstant Serving Global Testing Needs SolarConstant products are designed to meet a large number of standards as well as industry test methods such as DIN 75220, MIL-STD-810, IEC 61215, IEC 904-9, EPA 40-CFR/ SC03, BMW PR306.5, Renault 32-00-022, Telcordia GR-487-CORE and others. Atlas offers a complete series of SolarConstant luminaires to satisfy an array of global testing needs: SolarConstant MHG 4000/2500/1200/575: These luminaires utilize Metal Halide Global technology for full-spectrum solar simulation. Optical filters adjust the output for the best match to natural indoor/outdoor sunlight. They are ideal for solar simulators used to determine thermal heating effects of solar radiation such as fit and finish, dimensional stability or thermal transmission. They are also suited for identifying photodegradation effects of polymers and coatings such as cracking, color fading and other failures, or testing PV module performance. SolarConstant MIL: These luminaires utilize Metal Halide Global technology combined with a unique "multi-level" output for full-spectrum solar simulation. Especially useful for satisfying stringent MIL-STD-810G method 505.5 (Procedure I) - determination of heat produced by 24-hour cycles of solar radiation. It is also ideal for agro-science requiring diurnal cycles, e.g. plant growth studies and others. SolarConstant MH 1500/1200/1000: These luminaires utilize Metal Halide technology for specific high-UV level testing or to meet limited budget applications. Solar Constant UV 2000: These luminaires utilize Mercury technology for creating UV radiation (280 - 400 nm) and are used to study photo-aging effects caused by solar UV radiation only. In addition to the SolarConstant line of products, Atlas comolements its luminaire portfolio with Halogen technology for visible (VIS) and heat radiation (IR). IR-luminaires with 2000W / 1500 W are used to set up high-performance systems for testing heating effects similar to heating caused by sunligt. In addition to the SolarConstant line of products, Atlas comolements its luminaire portfolio with Halogen technology for visible (VIS) and heat radiation (IR). IR-luminaires with 2000W / 1500 W are used to set up high-performance systems for testing heating effects similar to heating caused by sunligt. From Outdoor Data to Laboratory Testing No environmental laboratory test is complete withut the confirmation and correlation to natural conditions. Atlas operates a number of outdoor exposure sites in key climate zones worldwide and can produce the natural exposure data you need. Using our expertise in both outdoor and accelerated testing, Atlas can assist you in reproducing outdoor conditions in your laboratory enabling your testing to reliable, fast and as realistic as possible. Test Chamber Examples Atlas has installed over 100 systems worldwide and is a leader in combining the technologies of testing with solar simulation. Below are examples of the most common test chambers with solar simulators: Climate test chamber with wind tunnel and solar simulator Climate test chamber with dynamometer and solar simulator Solar heat load test chamber with solar day cycling Climate test chamber with dynamic road simulation and solar simulator Custom solar simulator for PV module testing, Light Soak testing, I/V curve tracing Solar environmental Walk-in test chamber for component / product testing Atlas CESORA Atlas' CESORA (Calculation of Effective Solar radiation) software is extremely useful in the absence of measured outdoor data. With CESORA, you can calculate effective solar radiation for any time, day, month or year on any titled surface over any spectral range from 250-3000 nm. Positioning System To allow the SolarConstant solar simulator to move and replicate various natural solar conditions, a mechanical positioning system is typically installed. This enables motorized movement of the solar array within all desired spatial directions to simulate solar day cycles for example. Atlas offers both low-cost manual remote controls or full automatic alternatives that are integrated into the Atlas software. Positioning systems are typically customized towards the application and local test facility. Atlas will work with you to define the SolarConstant positioning system that will work best for you. Control System The operation of the SolarConstant system is handled by a dedicated operator interface. Atlas provides tailored menu-driven software for the programming and operation of each solar simulation system. Any solar simulation profile - for example morning, noon, afternoon, etc. can be stored and combined with various types of programmed test sequences for a complete integrated test program. For seamless operator interface, the Atlas designed solar control interface can be linked to the master IT environment of the test facility. We believe that a strong grasp of our customers' requirements is a key factor in developing a solution tailored to their needs. In order to simplify initial communications and understand your requirements more easily, please fill out the provided questionnaire under 'Downloads' and fax it back to +49-6105-9128-80.

MOOG GAT GMBH

Germany

GAT torsion motors are supplied as individual components or as complete torsion system consisting of torsion motor unit, application-specific control electronic s and hydraulic supply. Comprehensive consultation services from concept planning phase to commissioning complement our portfolio. GAT torsion motors consisting of a basic motor and a GAT rotary union are designed for quasi-static, pulsating and dynamic loads. Speed and torque as testing parameters are controlled independently. The torsion test rig with mechanical torsion application allows the energy-efficient testing of components at relatively low investment costs. Using a hydrostatic torsion motor in the test rig creates realistic and consistent testing conditions leading to test results very close to real-life conditions.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The microhardness testers of the UHL VMHT series provide semi- or fully-automatic low-load Vickers or Knoop hardness testing from 1 g to 2 kg. Using brilliant Leica optics and a high valuable load mechanism with fixed weights to apply the test force, repeatable and long time stable results are achieved. Even the basic model is equipped with a user friendly motrized turret, an optical focus helper and motorized load selection.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Load testing - Import exportNumber of results

4 ProductsCountries

Company type