- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser welding

Results for

Laser welding - Import export

KLN ULTRASCHALL AG

Germany

The KLN QSW 400 L is a modular laser welding machine. The advantage of the modular structure is that the central laser welding machine can remain unchanged in the various welding tasks and only the housing and its frame structure must be adapted to the actual welding task. Thus, a well-tried laser welding unit can always be used. Moreover, adaptions to other welding tasks can be easily integrated, e. g. with rotary table, tool carrier, conveyeor or sliding table. Laser: Water-cooled diode laser with 300 W optical output power Wave length 980 nm ±10 nm Pilot beam at 650 nm ±15 nm (<1 mW) Optical fibre suitable for wave length 780-1030 nm Focal distance of collimation 58 mm Focal distance f-theta objective 635 mm Operating distance 728 mm Operating field (scan field) 415 mm x 415 mm

Request for a quote

COHERENT, INC. - DEUTSCHLAND GMBH

Germany

The Performance Family consists of three different models of manual laser welders Performace Basic, Performance Unlimited and Performance Open. Depending on the configuration, they enable the processing of components either in a closed working chamber, a closed working chamber with lasersafe safety curtain, or open without a working chamber, depending on the size of the component to be processed. Optionally, the system can also be equipped with a motorized rotary axis and can thus also be used for very demanding tasks where precision and reliability are the critical factors..

Request for a quote

COHERENT, INC. - DEUTSCHLAND GMBH

Germany

The Select laser class 1 welding system offers maximum flexibility for complex welding tasks with 3 different operating modes (manual, semiautomatic and CNC), large working chamber space for bulky/heavy components and servo motorcontrolled linear axes. The system is easily controlled via a multifunctional joystick and/or a touchscreen display, which allows all inputs and parameters to be intuitively entered, managed and saved for recurring tasks.

Request for a quote

COHERENT, INC. - DEUTSCHLAND GMBH

Germany

The Coherent desktop laser is a universally applicable, compact system for manual welding tasks. To ensure reliability and high quality process results, the system features computercontrolled laser pulses, monitored cooling, easy workpiece positioning via the stereo microscope, and a welding assistance system. The efficient housing design provides a large work space, yet is compact enough to fit in tight spaces.

Request for a quote

COHERENT, INC. - DEUTSCHLAND GMBH

Germany

The Select laser welder is a freestanding, fully integrated system with a large workspace and unique control concept. Manual welding, joystickcontrolled deposition welding or complete CNC automation Equipped with a fiber laser or a pulsed NdYAG laser source, the Select offers a unique welding concept with four highprecision axes, short setup times and simple CNC programming. Parameter input is simple and requires no special knowhow via a multifunctional joystick and/or a large touchscreen.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-vibrating heat exchanger are used in a number of processes in which bulk solids have to be cooled, heated, dried etc. These special-purpose units are able to perform the heat exchange process during transportation. Usually, this occurs indirectly through the use of double bottoms to accommodate the heat exchange medium (oil, water, air, etc.). AViTEQ heat exchangers are employed in practically every industry (chemical, food, plastics, pharmaceutical, recycling and raw materials). The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits gentle product treatment optimised and customised modification to suit existing processes low wear and pra

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Spiral conveyor are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral conveyors are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral conveyors are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes. The bulk solids can be transported both upwards or downwards. Advantages & benefits energy and space-saving vertical conveying that's gentle on the material low-maintenance continuous operation easy-to-clean, hygienic design natural cooling of the bulk solid during the conveying process thanks to long dwell times bulk solids cooled either directly by air or indirectly by water through the use of double bottom or laser-welded Thermplate® bottoms as the spirals

Request for a quote

NANOSYSTEC GMBH

Germany

Exactly tailored to the respective process requirements of the devices, VersaWeld provides high productivity from the beginning. The application determines which laser source will be used and thus stainless steel, Kovar, Titan alloys and nonferrous metals can be efficiently processed. Typical devices for precision laser welding include sensors, micromotors, medical components and other miniature elements such as housings which require leak tightness.

Request for a quote

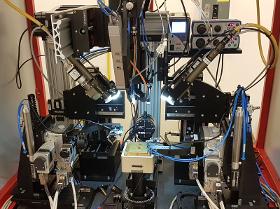

NANOSYSTEC GMBH

Germany

NanoHybrid provides a large degree of versatility. The active alignment, test and assembly station combines various assembly methods including gluing, laser welding or selective laser soldering. In addition, the station offers opto-electronic testing capability. Therefore, NanoHybrid is ideally suited for the development and small serial production in manufacturing companies or in research institutes. In such a product development area, an active alignment station needs to cope with opto-electronic and other precision devices with varying sizes and characteristics.

Request for a quote

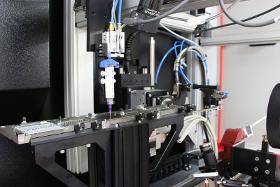

NANOSYSTEC GMBH

Germany

VersaHybrid is a semi or fully automated production system for complex assemblies which require a precision in the low micrometer regime. Assembly techniques include micro welding, selective laser soldering and gluing plus laser fine cutting. Various processing methods are combined in one station. Feeders, belts and robots allow for full automation.

Request for a quote

COHERENT, INC. - DEUTSCHLAND GMBH

Germany

The laser marking and engraving systems of the EasyMark series are among the most compact laser marking systems on the market. Depending on the configuration of the system most metals and nonmetals can be processed. A manual component loading device and cameraassisted positioning are just some of the features of the system. Control is via Coherent's powerful Visual Laser Marker (VLM) marking software, which offers numerous interfaces, support functions, 3D engraving, and more.

Request for a quoteResults for

Laser welding - Import exportNumber of results

12 ProductsCountries

Company type