- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- labelling machines

Results for

Labelling machines - Import export

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PDL model series for labeling Petri dishes from our special machine construction provides filled and sealed Petri dishes with a serialized DMC label in the minimum tolerance range at an output of 130 products/min. The system combines mechanical engineering, label material and thermal transfer printer. The Petri dishes from the previous filling/capping line are fed to the labeling system. By means of a clock star, the system transports the products through the various stations, such as labeling, the press-on unit and DMC inspection, where the grading (quality control) of the data matrix code takes place at the same time. In case of insufficient quality of the barcode, the product is ejected. By using our label dispenser RAPID SM we guarantee an accuracy of +-0.2 mm at a labeling speed of 60 m/min while maintaining the product quality. The signals are switched directly into the stepper motor card developed by us.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The TNC-DS series is used to label cylindrical products on the circumference. For this purpose, the product is manually placed in the product turning station. The labelling process is triggered by actuating the foot switch or the optionally available 2-hand control. The product is rotated, and the label is applied precisely to the circumference of the label. As standard, the model is available with different roll widths (100 to 300 mm) and different label applicators (60 to 250 mm wide) or print- and apply systems. Optionally, the labels can be aligned using a welding seam or other product features. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Depending on the operator, the output of this model is between 10 and 15 products/min.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RML labeling machine is suitable for wrap-around labeling of non-rigid cylindrical products - ampoule, cartridge, syringe labeling. The products are transported to the labeling station, which fixes the label on the circumference, by means of an intermittent roller conveyor. The labeling system is suitable for products such as ampoules, cartridges, lipsticks, syringes and vials and is therefore suitable for the pharmaceutical, medical technology, cosmetics and food industries, where reliable labeling and control processes are extremely important. Deviations and errors here can lead to life-threatening situations. From manual loading and unloading to fully automatic loading and subsequent collection of the products, this model is modularly expandable. Particularly narrow products such as ampoules or cartridges can also be processed using format sets (RML-FS).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

With the VFP labeller, pasta packages or other flat products can be labelled on the bottom or top. In various industries such as food or cosmetics, and especially pharmaceuticals and medical technology, accurate product labelling is important. Food packaging or folding boxes are often labelled on the top and bottom. Like all systems, this labeller from b+b is modularly expandable. Processing of different product sizes and formats is possible without tools by simply changing over from format to format. Your advantages here are short set-up times and easy handling. The fully automatic VFP labelling system enables you to label your products precisely - regardless of whether the label is to be applied to the top, the bottom or both sides.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This manual labelling solution was developed to apply one or more seal labels to folding boxes in small batches - before fully automatic lines are changed over to the product, the products are already sealed with this device. The seal label can be applied to all closure flaps as required. An ultrasonic fork sensor enables the processing of transparent and non-transparent sealing labels. Label roll-on across corners is clean and accurate. The solution for smaller, decentralized labeling jobs: — suitable for transparent/non-transparent (ultrasonic label sensor) — reliable, handy with handle bar — non-slip stand — easy setup — repeatable application of labels — core diameter: 76 mm — max. outer diameter: 200 mm — max. label width: 80 mm — label winding: outer winding

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

With the TNC-L model series, cardboard boxes and small cartons are provided with sealing or closure labels. The system can be infinitely adjusted to different formats. We determine the format range together with the customer. Optionally, labelling can also take place at several points - for this purpose, the product must be relocated in the system.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PAE range is an innovative new generation of pallet labellers that can label pallets on up to three sides with either pneumatic and/or electric traversing axles. The labels are printed with individual data in real time immediately before dispensing. The series is designed to integrate thermal transfer printing modules from different manufacturers. Automatic height adjustments are available as an option in order to Application heights on the pallet to start up. The complete traceability of products is essential nowadays, which is why interest in intelligent pallet labelling processes is so high. The system can handle label formats up to DIN A4 format, enabling product labelling according to the global GS1 standards.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Due to increasing product counterfeiting, many manufacturers are forced to make their products tamper- and counterfeit-proof. Legal requirements exist in some countries for this purpose. Our TE model was developed for this task. The system enables single-sided and/or double-sided seal labeling of pharmaceutical folding boxes and can also be used in the cosmetics industry. During the development, special attention was paid to the protection of the packaging as well as the format range of the products to be processed. The basic version labels folding boxes with format widths (in the running direction) of 50-250 mm at an output of up to 300 folding boxes per minute. Models for processing wider folding cartons are based on the same line concept. As an extension, the model series is available as a combination system (TE-PV) with a b+b serialization module and b+b LineManager. In this case, the printer and camera system are integrated into the system.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Our printing and apply systems from the CLM model series are designed for use in the final packaging predestined. To labelling of their cardboard boxes, printing widths from 54 mm to 216 mm (2“ to 8“) are available. In addition to the selection of the desired printing width the customer can choose between one- and two-colour printing. decide. The latter is e.g. helpful in the implementation of the GHS Regulation in the chemical industry. In interaction with our label design software Labelsplatform 4 you decide to choose the ideal and future-proof complete package.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

We offer the TNC-2F model for labelling large square containers such as canisters or cartons on one or more sides. For this purpose, the operator places the product in an adjustable product pick-up station. As soon as the operator actuates the foot switch, the labelling process is started, and the labels are applied. Model TNC-2F-2 | 2- sided labelling with 2 apply systems TNC-2F-3 | 3- sided labelling with 3 apply systems

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Our HSF-eco model is used for offline labelling of flat products such as empty pharmaceutical boxes, postcards or cardboard blanks. After loading the infeed magazine, the system unstacks the inserted products fully automatically and collects them again after labelling. The system can be refilled during operation and the processed products can be removed. In the basic version, product widths of 350 mm can be easily labelled. Models for processing wider products are optionally available.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Like all of our labelling systems, this model has a modular design and can be expanded at any time. The advantages such as low set-up costs, high availability and multiple use in different production lines are obvious. The adaptation to the different products takes place by simple adjustment of the machine components and is possible without tools. The VRM-DS model includes a 3-roller turning station and can be used for an output of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the products using a welding seam, print mark or other feature before labelling (target zone labelling). For larger quantities of up to 250 products/ min the VRM-RB model is used. Model: VRM-DS | Cylindrical and quadratic products | up to 60 products/min VRM-RB | Cylindrical and quadratic products | up to 250 products/min VRM-DSRB | Cylindrical and quadratic products | up to 250 products/min

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

For precise labelling, products with an accessible cavity are manually placed on a format mandrel. By actuating the foot switch or the optionally available 2-hand control, the labelling process is triggered, the product is rotated, and the label is applied precisely to the circumference of the product. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Optionally, the labels can be aligned using a welding seam or other product features (such as opening tabs or lid recesses for tubes). A pneumatic ejection makes the removal process superfluous and blows the well labelled products into a collection box

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RSA Series is designed to identify suspension springs with the appropriate load class based on an individual payload measurement result. The system receives the measurement results from the upstream system. The system is available as a single or double cycle version (depending on the required throughput). Simple linear axes, single- or twin-robot systems are used as handling systems. Since the labels are normally wider than the distance between the threads, the label is preformed (Ushape) before application to reach the labelling position before it is placed around the wire and finally fixed as a flag label. The data is inspected by a vision system and compared with the original measurement information at the outfeed of the system (verification). The labels are printed in the system with various data such as customer information, barcodes and line information. The data for this is made available via the main control of the production line.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Due to increasing product counterfeiting, many manufacturers are forced to make their products tamper- and counterfeit-proof. Legal requirements exist in some countries for this purpose. We have developed our HSS model series for this task. The system allows printing and inspection of pharmaceutical folding boxes on one and/or both sides and thus fulfills all requirements for product serialization. During development, great attention was paid to protecting the packaging as well as the format range of the products to be processed. In the basic version, folding cartons with format widths (in running direction) of 50-250 mm can be serialized at an output of up to 350 folding cartons per minute.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Due to lower storage costs and higher flexibility, more and more manufacturers rely on the processing of unprinted tubes and mark them with a label directly before filling. The labeler TEM model was developed for this purpose and is able to apply a label to the circumference of the empty, unsealed tubes. For this purpose, the products are transported via a clocked transport system to the labeling station, where they are previously aligned and stabilized by means of a format-specific mandrel. The model can optionally be extended to include infeed and outfeed magazines and/or steep conveyors into the tube filler. As a double-cycle variant, throughput can be doubled. Special sensor technology makes target labeling possible based on print marks or lid features. Models: TEM \ Empty, unsealed tubes \ 50 - 60 products/min TEM-2T \ Empty, unsealed tubes \ 100 - 120 products/min

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The basic concept of this system is to label form bottles on both sides without using format parts. The adaptation to the respective product takes place by simple adjustment of the machine components. The associated advantages are short set-up times, high availability and multiple use in different production lines. For a high placement accuracy of the labels, the products are precisely aligned on the transport path. Label formats up to 250mm height and cycle rates up to 250 labels per minute are possible. This makes it easy to cover a wide range of products. FM | Form bottles one- oder two-sided | up to 250 products/min FM-DS | Form bottles und cylindrical products (rotating station) | up to 60 products/min FM-RB | Form bottles und cylindrical products (rotation belt) | up to 250 products/min FM-DSRB | Form bottles und cylindrical products | up to250 products/min | (combination of rotating station und rotation belt)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The systems of the VEE model series are ideally suited for labelling medium-sized containers such as buckets, paint cans and canisters in all industries such as food, chemicals, paints and varnishes - regardless of whether these are oval, round or rectangular plastic or metal containers. Depending on the customer's requirements, the products can be aligned before the labelling process, and any plastic or metal handles can be brought into the position required for labelling. Optionally, the labelling system can be expanded to include additional labelling stations for applying a lid label, if required.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The system is used for labelling or printing flat products such as postcards, flat folding boxes, mailing bags or textile blanks, regardless of the format. The products are fed into the loading chute by the operator and are then destacked layer by layer from below and fed past the labeling or printing or inspection unit. The finished products are then collected in an exit chute or a collection box. This system was developed for a capacity range of up to 100 products/min. For processing higher numbers of products/min, the HSF model series is available which, in addition to a longer conveying distance for setting up different stations also provides the option of a product ejector to automatically remove NIO products from the process and collect them in a separate collection box. The tool-free adjustment enables the shortest changeover times for batch/product changes.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Thanks to the TNC-F model series, semi-automatic labelling of shaped bottles becomes very easy. The front and back labels should be on a carrier material. The product is inserted into a product pickup device. As soon as the 2-hand operation is activated, the system starts to pick up the product in the two format pucks, rotates and aligns the product before the front and back labels are applied exactly to the desired positions. By exchanging the format parts of the product pick-up device, cylindrical or angular products can also be processed and labelled with several labels in addition to the shaped bottles.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The label dispensers of the Rapid Easy model series are ideally suited for use in industrial environments due to their robust mechanical construction. The systems apply pre-printed labels quickly and accurately to products or their packaging. The label dispensers are suitable for many labelling requirements. Thanks to its compact design, the Rapid Easy is particularly space-saving and can be easily integrated into any production line. The modular design of the systems was the focus during the development of the label dispenser. Almost every label requirement can be realised due to the modular system. The systems are available with 100 mm and 160 mm and each as (right) RH and (left) LH version.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The requirements for product labelling are increasing and becoming more and more diverse. Track and Trace, product tracing, quality assurance, GS1 regulations require secure and reliable application of variable data. This applies to almost all industries, whether logistics, pharmaceuticals, food industry or chemicals such as agrochemicals. When printing variable data such as graphics or Data Matrix, barcodes, QR codes and comparable code types, uncompromising quality must be implemented. The EDS 420i and EDS 620i printing and dispensing systems are designed for industrial use and enable you to label your products and their packaging precisely, reliably and quickly using different applicators and label transfer modules. The modular design of the systems was the main focus in the development of the printing and dispensing systems

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The workstation enables the manual serialisation of pharmaceutical packs and their aggregation into shipping cartons. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system and then manually placed in a shipping carton. As soon as this is filled, the downstream thermal transfer printer creates an individual serialisation label. The correct print data and print quality are monitored by a camera system. The operator places the drug packs to be labelled at a reference edge of the conveyor belt. As soon as the printer has printed the serialisation data, it is checked for correctness by the integrated image processing system. In case of an error, the product stops at a certain position, which is marked by red LEDs. Depending on the number of products in the shipping carton/number of aggregation levels, approx. 10-12 products/min are serialised.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Labelling machine for wrap-around labelling Basic concept of the system for bottle labelling and can labelling: With the aid of the fully automatic VRM labeller, different cylindrical or square products can be labelled quickly and precisely on the circumference - wrap-around labelling. The machine is therefore used in many industries, from pharmaceuticals to food and cosmetics. The VRM series is suitable for bottle labelling, can labelling, vial labelling or for comparable containers such as jars or bottles. Several different formats can be covered simultaneously with one model. The VRM-DS labelling system includes a 3-roll turning station and is used for outputs of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the containers on the basis of a weld seam, print mark or other feature before labelling (target labelling).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

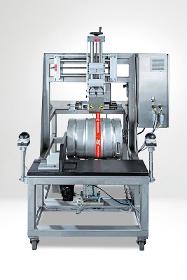

The TNC-GG model series was developed to apply one or more labels to large cylindrical containers at the circumference. Instead of using „die-cut“ labels, it is also possible to handle continuous label material from the roll. Depending on the size of the product, the material is cut inside the system. The largest area of application for these systems is in the beverage industry, where beverage barrels (KEGs) are provided with a deposit banderol on the circumference and thus clearly indicate the owner of the returnable containers. Highly permanent label material is used for these applications, which can no longer be removed from the product without leaving residues. We also offer fully automated solutions for this.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The semi-automatic labeling machine TNC-R was developed for the all-round labeling of tubes. Small batches can be labeled quickly and precisely with the labeller. The tubes are placed manually in the labeling system. As soon as the 2-hand operation is activated, the automated labeling process starts. The product is rotated and shifted, then the wrap-around label is applied exactly to the product. A printing unit can be integrated for individual labeling of the tubes. You can easily print the labels yourself inline. The integration of a printing unit is suitable, for example, for laboratory tubes or sample vessels that have to be provided with individual data.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Fully automatic labelling machine for labelling drums in accordance with the GHS Directive. All chemicals are subject to mandatory classification and labelling before they are placed on the market, and they are often marketed in drums and hobbocks of various sizes. This places increased demands on the flexibility of the labelling unit in terms of print data, multi-colour printing and application height (labelling height). Often, several labels are applied to the circumference of the keg (product label, hazardous goods label(s) and logistics label. For this purpose, the system can be equipped with several label dispensers and/or several printing and dispensing systems. Labelling can be carried out in continuous operation or at a standstill. Depending on the application and labelling requirements, the labelling system can also be positioned at a drum labelling station.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Fully automatic labeller \ Label printing and dispensing system for labelling bags Basic concept of the label printing dispenser: Bag labelling with variable data: The EDS620i-VCB label printing and dispensing system was developed for labelling sacks. The label is applied to the bag via a pneumatic label transfer unit. To achieve a precise application result, a pneumatic pressure roller is used. The sack label is then recorded fully automatically via a barcode scanning station and reported to the b+b Siterserver. The basis of the pressure dispensing system is the EDS 620i label pressure dispenser. This is designed for industrial operation and enables you to label your products and their packaging precisely, reliably and quickly using different applicators and label transfer modules.

Request for a quote

STI GROUP / STI - GUSTAV STABERNACK GMBH

Germany

The self-adhesive label is the most important communication medium for the plastic container from Unilever in Hungary. The labels are produced on rolls and applied by machine. The label is designed in the Hungarian national colours and is finished with offset printing.

Request for a quoteResults for

Labelling machines - Import exportNumber of results

30 ProductsCountries

Category