- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial irons

Results for

Industrial irons - Import export

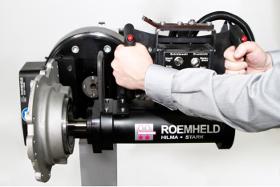

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

Ø32x6 mm 24.5 kN, with body 500 bar, see page B1.480

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

Ø32x6 mm 24.5 kN 500 bar, see page B1.480

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

Hydraulic pull-in device for mounting bearings max. pulling force 100 kN, stroke up to 200 mm, horizontal design Application The bearing press is suitable for the simple mounting of bearings, plain bearings or sleeves/bushings by hydraulically pulling them into the bearing seat. Main areas of application - Industrial assembly workstations - Mounting bearings in housings - Maintenance work - Bearing assembly on large/heavy components Description The bearing press is designed for the hydraulic insertion of bearings into housing components and is available in a horizontal design. Guided on a knuckle boom crane with a balancer (not included in the delivery), the bearing press can be used ergonomically anywhere and can also be mounted on a trolley. The pullin cylinder can be used either from the right or left by converting the hydraulic cylinder. The device is operated by means of a twohand control.

Request for a quote

GEORG H. LUH GMBH

Germany

Micaceous iron oxide (Fe2O3) is a pure, natural product in the oxide class of minerals. Its hardness according to Mohs is 6.0 to 6.5, with a density of 4.8g/cm³. In addition to standard types for heavy-duty corrosion protection, newly developed product types especially well suited for thin-film corrosion protection and also as a zinc dust replacement are available. For the ceramics and plastics industry, we supply micaceous iron oxide as a metallic effect pigment in very coarse, narrow grain size ranges.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

TSCHAN® TKVSG (SEB-design) Construction and design acc. to operation sheet of German Steel Iron Industry SEB 666212 Hub and housing of reinforced material - Additional retainer rings improve axial fixing of the barrel by created axial rope forces General features Torsionally rigid, compensate for angular and axial shaft misalignment Torque transmission by hardened steel rollers For use in crane/ hoist applications to support the rope drum Outer diameters up to 850 mm Wear indication Bores up to 400 mm Torques up to T Kmax = 685,000 Nm FEATURES AND APPLICATIONS TSCHAN TK barrel couplings are recommended for installation in crane lifting mechanisms, to connect the cable drum with the gearbox output shaft, as well as in winch conveyors and platform hoists. By selecting the coupling size (Table 1a/1b in the catalogue), it is necessery to consider the radial load (S T(N)), the dimension of the gearbox shaft (d min – d max) and especially the transmission torque (T) with the...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quoteResults for

Industrial irons - Import exportNumber of results

11 ProductsCountries

Company type