- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- guide rollers

Results for

Guide rollers - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

Flexible and powerful: the conveyor derinder ASB 600 for artisanal and medium-sized companies with a wide range of applications. The combination machine can be used open with a carriage table or closed with a height-adjustable pressure device and infeed belt. In conveyor operation, all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham are derinded automatically. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Optimal results: clean removal of the rind without residues Infinite adjustment of the rind/cutting thickness Equipped with two operating speeds as standard Compact, movable via fixed and guide rollers Option: Pressure rollers in various hardnesses and air pressing roller Discharge belt Special voltage

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

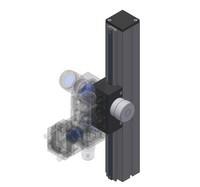

The linear stages of the PT series are especially designed to provide high accuracy in compact dimensions. The bearing design without runnung-in provides an even higher accuracy than the LT series. The linear stages of the PT series are particularly suitable as vertical axis. normalized aluminium alloy, black or pale anodized cross roller guides, anti-backlash pre-loaded ball screw, anti-backlash pre-loaded

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The linear stages of the LT series are especially designed to provide high accuracy in compact dimensions. The bellows are protecting the bearings, spindles and scales from external influences. normalized aluminium alloy, black anodized anti-backlash pre-loaded cross roller guides or profiled rail guides anti-backlash pre-loaded ball screw

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

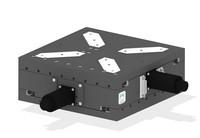

The closed frame XY stages are especially designed to provide ultra high accuracy in compact dimensions. By the modular concept, they can be equipped with different motors and measuring systems. The close frame XY stages are particularly suitable for incident light and topographic applications. normalized aluminium alloy, black anodized cross roller guides, anti-backlash pre-loaded when equipped with motorized drives, anti-backlash pre-loaded ball screws are used

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The open frame XY stages KT are especially designed to provide high accuracy in compact dimensions. By the modular concept, they can be equipped with different motors and measuring systems. The open frame XY stages are particularly suitable for transmitted light applications. normalized aluminium alloy, black anodized cross roller guides, anti-backlash pre-loaded when equipped with motorized drives, anti-backlash pre-loaded ball screws are used when hand driven, with quick-release for coarse adjustment and +/- 5 mm fine-pitch thread plane parallel glass top to put on the specimen

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

The control elements are equipped with dovetail guides ("hard-slide" coating) or cross roller guides and are rack & pinion, micrometer or worm driven. They have minimized backlash and a straightness accuracy within a few microns. The control elements can be equipped with one or two knobs or without any knob. Multi-axle systems can be built up using the control elements and corresponding connection elements. An intermediate plate (B40-RP) is required to attach the tube elements.

Request for a quote

BIMATEC SORALUCE ZERSPANUNGSTECHNOLOGIE GMBH

Germany

The SORALUCE KB-150-W series is a modern table-type horizontal boring machine for efficient multi-face machining of large and precision workpieces with weights of up to 40,000 kg. The heavy cast iron design and INA linear roller guide systems guarantee maximum stability and precision. The automatic milling head changing system provides exceptionally high flexibility thanks to the automatically lowering milling heads for machining at any angle. Longitudinal (X): 3,000 – 5,000 mm Vertical (Y): 2,600 – 3,200 mm Cross (Z): 2,000 – 5,000 mm

Request for a quoteResults for

Guide rollers - Import exportNumber of results

8 ProductsCountries

Company type