- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- equipment operating

Results for

Equipment operating - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

Flexible and powerful: the conveyor derinder ASB 600 for artisanal and medium-sized companies with a wide range of applications. The combination machine can be used open with a carriage table or closed with a height-adjustable pressure device and infeed belt. In conveyor operation, all cuts, such as cheek, belly and loin of pork, as well as fat on shoulder and ham are derinded automatically. In open operation, suitable for derinding all round cuts, such as ham, shoulder or knuckle. Advantages Optimal results: clean removal of the rind without residues Infinite adjustment of the rind/cutting thickness Equipped with two operating speeds as standard Compact, movable via fixed and guide rollers Option: Pressure rollers in various hardnesses and air pressing roller Discharge belt Special voltage

Request for a quote

AAAGILER GMBH

Germany

VDE approved mat designed for use in front of open switchboards and high voltage equipment. Provides safety for operatives against electric shocks. Fine fluted surface has slip-resistance benefits. Tested to 50,000 volts according to DIN EN 60243-1 (VDE0303 part 21) IEC 60243-2:1996

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

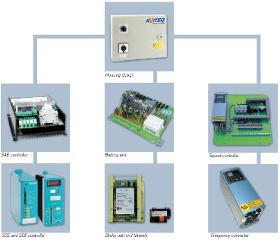

The AViTEQ Vobtronic units are fully equipped controllers for the operation of vibrators. About a variety of standard features and special designs the controllers can be used in many different industries and variable to adapt to the work environment. VIBTRONIC® -controllers are designed to supply AC voltage to control magnetic vibrators. They operate according to the principle of voltage control (phase-fired control). For all standard voltages in the 50 and 60 Hz main supply, AViTEQ has a suitable controller available in either a built-in or housing design. The controllers have voltage compensation for fluctuations in the main supply and some models have a limited control that rotects the magnetic vibrator from impact. The setpoint specification can be set using a potentiometer or an external setpoint (0-10 VDC or 0/4-20 mA). Information regarding operational status can be read from the integrated status relay and LEDs. Depending on the model, a vibrator current up to 100 A is possib

Request for a quote

PULSARLUBE GMBH

Germany

The Pulsarlube MS electromechanical automatic grease lubricator is designed to operate in synchronization with the equipment on which it is installed. As long as the equipment is operating, the Pulsarlube MS will dispense the preset amount of lubricant so that any loss or waste of lubricant can be prevented. The Pulsarlube MS electromechanical automatic grease lubricator is designed to operate in synchronization with the equipment on which it is installed. As long as the equipment is operating, the Pulsarlube MS will dispense the preset amount of lubricant so that any loss or waste of lubricant can be prevented. If the equipment is not operating, then the Pulsarlube MS goes into "stand-by mode" and does not dispense lubricant until the machine goes back into operation.

Request for a quote

PULSARLUBE GMBH

Germany

The Pulsarlube PLC electromechanical automatic grease lubricator is specially designed to be fully integrated as well as be synchronized to a PLC system .Kindly offers two types of PLC lubricator, Month and Interval type for wider range of usage. Can remotely send a dispensing signal to the lubricator when lubrication is needed Precise lubrication on demand Can lubricate up to 8 lube points (Max. 6m) High output pressure of 30~60kgf/cm² (425~850psi) User can control dispensing rate based on hours of operation of equipment(INTERVAL TYPE)

Request for a quote

PULSARLUBE GMBH

Germany

The Pulsarlube MSP electromechanical automatic grease lubricator is designed to operate in synchronization with the equipment on which it is installed. As long as the equipment is operating, the Pulsarlube MSP will dispense the preset amount of lubricant so that any loss or waste of lubricant can be prevented. Ideally suited for applications where lubrication is to take place only when the machine is in operation and where a feedback signal to PLC is required Any over-lubrication issue can be prevented No needs to change the internal battery pack for up to 5 years (externally powered) Cost effecitve by use of replaceable grease pouch only Selectable grease pouch : 60, 125, 250, 500ml Available dispensing periods: 60ml : 1~12 months 125,250ml : 1,2,3,6,12 and H month 500ml : 1,2,4,6,12,18,24 and H month

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Equipment operating - Import exportNumber of results

6 ProductsCountries

Company type