- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- du-plate

Results for

Du-plate - Import export

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We manufacture individual parts and assemblies according to drawings, data or samples. We have a wide range of profiles in different steel grades and aluminum in stock. Our machinery enables us high flexibility.

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.tex ® deva.tex ® is a high performance self-lubricating sliding material with a glass fiber reinforced carrying layer. The machinable sliding layer consists of fibers which are embedded in epoxy resin. The resin carries PTFE as lubricant for excellent tribological performance. deva.tex ® bearings are available up to 1.000 mm and are characterized by a very high corrosion and wear resistance. They are insensitive to contamination as well as to vibrations and shock loads. In addition to standard dimension, special geometries can be machined. Max. possible outer diameter 1.000 mm Applications Water turbines, earth moving equipment, hydromechanical engineering equipment, agricultural machines, railroad applications, shut-off valves, chemical industry and many more. Structure 1. Sliding layer: reinforced polyethylene fibers embedded in epoxy resin and PTFE 2. Glass fiber reinforced carrier

Request for a quote

AAAGILER GMBH

Germany

"Utility location is the process of identifying and labeling public utility mains that are underground. These mains may include lines for telecommunication, electricity distribution, natural gas, cable television, fiber optics, traffic lights, street lights, storm drains, water mains, and wastewater pipes. In some locations, major oil and gas pipelines, national defense communication lines, mass transit, rail, and road tunnels also compete for space underground." White with red frame fire services (hydrants, suction points etc.) Blue drinking water Yellow gas Green sewage and drain lines Orange hot water/steam lines for district heating White or high-voltage power lines and telecommunication cables Grey Brown pipelines for oil and other flammable liquids

Request for a quote

AAAGILER GMBH

Germany

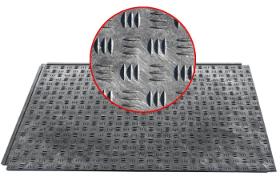

Material: PVC recycelet Dimensions (suitable for Euro pallets): Length: 1200 mm width: 800 mm Height: 43 mm Size laid. 1160 x 760 mm (floor panels are laid overlapping) Weight: 34 kg Minimum order quantity: 34 pieces Matching ramp parts available

Request for a quote

HEINZE & STRENG GMBH

Germany

In the wire and cable industry, wear plates are an important component in the production process. To increase the lifespans of the plates, we subject them to thermal treatment. The “slip-in” design further minimizes the repair costs. Wear plates available from Heinze & Streng with conventional or “slip-in” design.

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Needled or perforated parts in any design, produced according to customer requirements

Request for a quote

MPT DOSING GMBH

Germany

Controller for electroless nickel baths / Controller for electroless copper baths Controller for electroless nickel baths Nickel controller with flow-through sensor Walchem's WNI Nickel Controllers are optoelectronic on-line analyzers that measure the actual concentration of nickel in solution. The WNI410 is available as nickel-only, or with a pH control option which may be added in the field. Two separate pump outputs for nickel and reducer and another for pH are used, each of which is capable of totalizing either pump on-time, volume pumped, or metal turnovers. Integrated data logging is available to validate system performance. With a USB memory stick data and event logs that include nickel measurements, and relay status can be extracted. Download logs from the USB stick to a PC. Product features: Concentration Read in Units Selectable between grams per liter (g/L) or ounces per gallon (oz/gal). Backlit digital display also acts as a bar graph for a continuous "visual summar

Request for a quote

JINTIAN COPPER

Germany

Main products: HPb59-1、HPb60-2、H62 and other grades of leaded brass plates Product characteristics: Strong corrosion resistance, good elasticity, good formability and weldability, good strength Applications: Copper key blanks, copper engraving, electronic connectors, handicrafts Production capacity: 25,000 tons Honorary titles: Zhejiang Famous Brand Product, China's Top 5 Copper Strip Company

Request for a quote

KLN ULTRASCHALL AG

Germany

Basically the TOOLMASTER versions vary by their tool design, their size of useable surface and the degree of automation. All versions are suitable for high temperatures and optionally equipped with fire protection engineering, which quickly separates the tool in case of energy drop or timeout. KLN also manufactures special machines adapted to your individual requirements. TOOLMASTER "Basic" as well as type HE 50/30 are standard machines. The versions "Advance", "Semi-Automatic" and "Automatic" are made with tools in sandwich design. This makes possible the handling of upper tool, hot plate element and lower tool as a compact unit. They are designed particularly for quick and frequent production changes. The HE/SA has a horizontal concept with servo-drive technology for quick and precise movements. The TOOLMASTER CC has been developed for applications with two welding tasks in one cycle. Almost all machine versions can be provided with pneumatic or servo-motor drives.

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

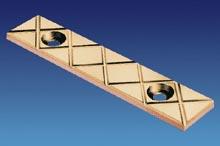

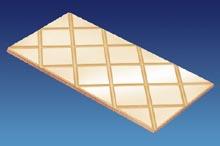

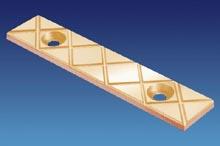

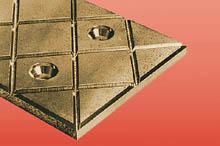

Where to use deva.eco ® deva.eco ® bearings are thin-walled, rolled CuSn8 parts provided with depots for use with lubricants. They feature high-load capacity enabling compact, high-performing, low-maintenance bearing locations. There are three basic variants: deva.eco ® 9 as variant with rolled-in diamond-shaped lubrication recesses. This type is primarily designed to cope with cases where surrounding construction elements such as gear wheels are oil lubricated. Equally suitable are commercially available, pumpable greases or pastes. Like deva.eco ® 9, deva.eco ® 8 also has lubrication recesses. However, these are filled with a solid lubricant, thus permitting operation without additional lubrication. If greater demands are made on grease supply, deva.eco ® 7 with end-to-end lubrication holes would be the type to use. This variant is less suitable for oil lubrication due to its design. Applications Agricultural machinery, hydraulic systems, bearings for impact loading and...

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.glide ® deva.glide ® is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. deva.glide ® maintenance-free bearings, without the need for lubrication with oil or grease are recommended for large bearings. have a low coefficient of friction have high wear resistance provide long life Applications Underwater equipment, offshore industry, iron foundries and steel works, heavy machinery, cranes and conveyors, deep and open cast mining machinery, construction and earth-moving machinery and many more. Structure 1. Bearing surface with running-in film 2. Solid lubricant ingots 3. Bearing material (bronze)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm/9P deva.bm ®/9P is a self-lubricating bi-metal sliding material. The sliding layer is applied to the stainless steel back in a combined rolling/sintering process. The lubricant in deva.bm ®/9P is microscopically distributed PTFE which leads to significantly reduced friction and wear figures. deva.bm ®/9P is the optimum material for p>25 N/mm² and has its best performance at slow speeds and intermittent service. Applications Water turbines, injection molding machines, packing machinery, food and beverage industry, printing machines, shut-off values, hydromechanical engineering, tire molds, construction equipment and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (PTFE) 4. Stainless steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.bm ® deva.bm ® is a thin-wall, self-lubricating bearing material suitable for hostile environments, high or dynamically loaded applications or where lubrication is difficult, unreliable or impossible. It consists of a steel backing with a deva.metal ® bearing layer. deva.bm ® offers basically the same bearing characteristics as deva.metal ®: but is capable of even higher loads and offers an economic solution to many bearing problems Applications Water turbines, injection moulding machinery, packing machinery, printing machines, construction equipment, shut-off valves, tire moulds and many more. Structure 1. Low-friction surface film 2. Bearing layer (bronze) 3. Solid lubricant (graphite) 4. Steel backing

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Du-plate - Import exportNumber of results

17 ProductsCountries

Company type