- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- forming pins

Results for

Forming pins - Import export

KLN ULTRASCHALL AG

Germany

The ultrasonic riveting makes possible an interlocking bonding of two thermoplastics or of thermoplastics with dissimilar materials, e. g. thermoset materials or metals. In this process the sonotrode serves as a re-forming tool. It determines the forming of the riveting pin. During the holding time (cooling phase) the sonotrode serves also as fixation stamp, thus the melted material cools down under pressure.

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. During the heating-up phase the hot air riveting does not get into contact with the material. A continous hot air flow heats up the riveting pin. Here the forming of the riveting head is carried out with a cold stamp in a separate station. By the cooling phase next in line a lower relaxation of the plastic material is achieved by pressure and mold constraint

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

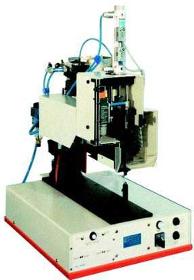

TYP A 042 Round pin inserter Description The Streckfuss inserting device Type A 042 offers the economical solution, for the mechanised insertion of round pins, solder posts and or - lugs into p. c. boards. With this device, nearly all customer forms of round pins, solder posts / - lugs can be processed. The loose components are filled into the sorting pot of the vibration conveyor. Trough barriers in the helical of the conveyor, the components are ordered. After positioning, the components are handed to the loading slider, which supplies the components to the inserting tool. Working with this device is save and easy: For assembling, hold the p. c. board with both hands on the edges, and place it under the inserting tool. The p. c. board now lies at the bottom of the pressure stamp, while the tooling pin hole is placed directly under the solder post / - lug shaft looming out of the inserting tool. This has the function of a locating pin. The p. c. board is lifted parallel, so the components shaft enters the tooling pin hole. The insertion process is triggered by a foot switch. Components

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Forming pins - Import exportNumber of results

3 Products