- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flange pipes

Results for

Flange pipes - Import export

DALMINEX GMBH

Germany

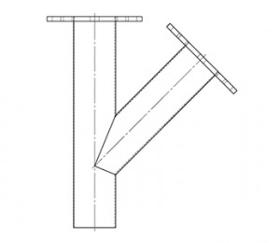

Installation piece for clean drinking water

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Stainless steel flanges are a crucial component in various piping systems, providing ease of assembly and strength in connecting pipes, valves, pumps, and other equipment. They serve as a plate for covering or closing the end of a pipe and are commonly used in plumbing, oil and gas, petrochemical, and food industries due to their durability and corrosion resistance. Types and Specifications Stainless steel flanges come in several types to suit different applications: Weld Neck Flanges: Designed to be welded to the pipe. Suitable for high-pressure applications. Slip-On Flanges: Easily slide over the pipe and are welded in place. Socket Weld Flanges: Used for smaller, high-pressure piping. Threaded Flanges: Attached without welding, ideal for low-pressure applications or pipes with a thin wall. Blind Flanges: Used to seal the end of piping systems or pressure vessel openings. Lap Joint Flanges: Used with stub end fittings for applications requiring frequent dismantling.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste TA. High temperature assembly paste Description Castrol Molub-Alloy Paste TA (previous product name Castrol Optimol Paste TA) is a paste for screw connections up to +1100 °C. It is used as an assembly paste and prevents sticking, welding and scaling. Molub-Alloy Paste TA ensures good separation and sealing in high-temperature and wet areas as well as in aggressive media. Application Molub-Alloy Paste TA is used as an assembly aid for components at risk of corrosion, temperature and environmental stress, such as screws, bushings, valves, flange and pipe screw connections, form-fitting components, seals, stuffing boxes and packings as well as for metal pairings of light metal against steel. Molub-Alloy Paste TA is used as a base and thin film lubrication for sliding surfaces subject to high thermal loads.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For mounting screwed connections, e.g. at combustion engines, threads on pipe fittings, flange joints and fittings of superheated steam lines, exhaust pipe and combustion chamber screwed connections, gas and oil burner mounting bolts To prevent burning together, seizing or rusting-on of screwed connections at water influence Suitable for brake systems of vehicles Advantages and benefits Excellently suited for preventing binding of threads exposed to high temperatures, corrosive environments and moisture Highly effective due to high level of pressure absorption Excellent corrosion protection Absolutely resistant to fresh water and sea water Extremely adhesive No classification according to (EG) No. 1272/2008 For best adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first (for example, with a wire brush) and then with OKS 2610/OKS 2611 universal cleaning agent. Use a brush, spatula or similar

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembling screw threaded connections subjected to high temperatures and corrosive influences Screwed connections at pipe fittings, flange joints and fittings in superheated steam lines Combustion chamber screwed connections and mounting bolts of gas and oil burners Screwed connections at combustion engines, exhaust systems, silencers and exhaust gas pipe connections Advantages and benefits Allows reliable non-destructive dismantling even after longer operating period under high operating and ambient temperatures Provides an optimal ratio of screw pretension and tightening torque Electrically conductive To achieve optimal adhesion clean the thread or the sliding surface first mechanically and then with OKS 2610/OKS 2611 universal cleaner to remove soiling as well as any lubricant residues. Use a brush, spatula or similar to apply a sufficient amount of paste to the head or nut contact surface and to the thread. Spray on evenly OKS 241 spray. The paste will also act as a sealant.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembling screw threaded connections subjected to high temperatures and corrosive influences Screwed connections at pipe fittings, flange joints and fittings in superheated steam lines Combustion chamber screwed connections and mounting bolts of gas and oil burners Screwed connections at combustion engines, exhaust systems, silencers and exhaust gas pipe connections Advantages and benefits Allows reliable non-destructive dismantling even after longer operating period under high operating and ambient temperatures Provides an optimal ratio of screw pretension and tightening torque Electrically conductive Also available as spray version OKS 241 To achieve optimal adhesion clean the thread or the sliding surface first mechanically and then with OKS 2610/OKS 2611 universal cleaner to remove soiling as well as any lubricant residues. Use a brush, spatula or similar to apply a sufficient amount of paste to the head or nut contact surface and to the thread.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of screw connections of high-strength steel subject to high temperatures, corrosive influences in chemically aggressive environments, e.g. on gas and steam turbines in power plants, combustion engines, threads on pipe fittings, flange joints and fittings in superheated steam lines, exhaust pipe and combustion chamber screwed connections etc. Parting lubrication of materials with a tendency to seize up, e.g. V2A, V4A and high-temperature steels Advantages and benefits Excellently suited for preventing seizing and binding Highly effective against corrosion affects Free of lead compounds, sulphides, chlorides and fluorides For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply paste evenly in sufficient amount onto head/nut support and thread or onto the sliding areas with brush, spatula, etc.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Drop-forgings of carbon and alloyed steel, nickel, duplex, titanium and superalloys like Monel® or Hastelloy®, Inconel®, Incoloy® for pressurized components like forged valves or valve parts like bodies and yokes or bonnets, flanges for boiler systems, fittings for piping, non-corroding parts for shipbuilding, marine technology, slings and lifting gear, hooks, eyebolts, nuts, chain links, military vehicles, transportation and defense. Every nut, bolt, and screw - forgings for harsh environments: forged valve bodies, bonnets, yokes and flanges, pipe connections, pressure applications like boiler parts, hoists, chain links, eyebolts, hydraulic components, corrosion and acid-resistant parts for chemical and fertilizer industries, as well as shipbuilding and drill equipment. Pressure equipment and nuclear power (valves, boilers, piping): PED 2014/68/EU, AD 2000-W0, ASME/ASTM, KTA, RCC-M Shipbuilding and maritime industry ABS, BV Marine & Offshore, DNV, LR Shipping, ClassNK

Request for a quote

BDSENSORS GMBH

Germany

The stainless steel probe LMK 382H has been designed for continous level measurement in waste water, waste and higher viscosity mediums. Basic element is a robust and high overpressure capable capacitive ceramic sensor e.g. for low levels. Features: — nominal pressure range 0 ... 60 cmH2O up to 0 ... 200 mH2O — accuracy: 0.1 % FSO — diameter 39.5 mm — HART®-communication (setting of offset, span and damping) — permissible temperatures up to 85 °C — high overpressure capability — high long term stability Optional Features: — IS-version Ex ia = intrinsically safe for gas and dust — mounting with stainless steel pipe — flange version — diaphragm pure ceramic (99.9 % AI2O3) — accessoires e.g. assembling and probe flange, mounting clamp

Request for a quote

BDSENSORS GMBH

Germany

The stainless steel probe LMK 382 has been designed for continous level measurement in waste water, waste and higher viscosity media. Basic element is a robust and high overpressure capable capacitive ceramic sensor e.g. for low levels easily. Features: — nominal pressure: 0 ... 40 cmH2O up to 0 ... 200 mH2O — accuracy: 0.35 % (opt. 0.25 %) FSO — diameter 39.5 mm — especially for sewage, viscous and pasty media Optional Features: — IS-version Ex ia = intrinsically safe for gas and dust — mounting with stainless steel pipe — flange version — diaphragm pure ceramic (99.9 % AI2O3) — different kinds of cables — different kinds of elastomers

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

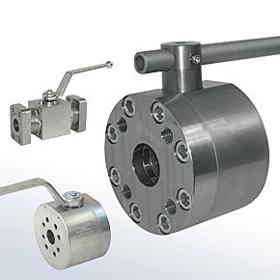

Round Body Ball Valves with ISO Flange Connections BBV2D1/BBV2D2 ▪ Two-way high-pressure round body ball valves designed for use as on/off devices for hydraulic applications ▪ For direct ISO flange connection according to ISO 6164 ▪ Pressure range: up to 400 bar / 5800 PSI (depending on size and material combination of the ball valve) Please note: The final maximum working pressure is determined by flange and pipe/tubing rating.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Round Body Ball Valves with Cetop Flange Connections BBV2Y1/BBV2Y2 ▪ Two-way high-pressure round body ball valves designed for use as on/off devices for hydraulic applications ▪ For direct ISO flange connection according to Cetop RP 63 H ▪ Pressure range: up to 400 bar / 5800 PSI (depending on size and material combination of the ball valve) Please note: The final maximum working pressure is determined by flange and pipe/tubing rating.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Block Body Ball Valves with SAE Flange Connections BBV2E/BBV2S ▪ Two-way high-pressure block body ball valves designed for use as on/off devices for hydraulic applications ▪ With standard and extended SAE mating flange connectors according to ISO 6162-1/2 and SAE J 518 C ▪ Pressure range: up to 420 bar / 6000 PSI (depending on size and material combination of the ball valve) Please note: The final maximum working pressure is determined by flange and pipe/tubing rating. Forged Body Ball Valves with SAE Flange Connection FBV 2E/ FBV 2S ▪ Two-way high-pressure forged body ball valves designed for use as on/off devices for hydraulic applications ▪ With standard and extended SAE mating flange connectors according to ISO 6162-1/2 and SAE J 518 C ▪ Pressure range: up to 420 bar / 6000 PSI (depending on size and material combination of the ball valve) Please note: The final maximum working pressure is determined by flange and pipe/tubing rating. Round Body Ball Valves with SAE Flange...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Block Body Ball Valves with SAE Flange Adapters BBV22/BBV23 ▪ Two-way high-pressure block body ball valves designed for use as on/off devices for hydraulic applications ▪ With standard and extended SAE split flange connectors according to ISO 6162-1/2 and SAE J 518 C ▪ Pressure range: up to 420 bar / 6000 PSI (depending on size and material combination of the ball valve) Please note: The final maximum working pressure is determined by flange and pipe/tubing rating. Forged Body Ball Valves with SAE Flange Adapters FBV22/FBV23 ▪ Two-way high-pressure forged body ball valves designed for use as on/off devices for hydraulic applications ▪ With standard and extended SAE split flange connectors according to ISO 6162-1/2 and SAE J 518 C ▪ Pressure range: up to 420 bar / 6000 PSI (depending on size and material combination of the ball valve) Please note: The final maximum working pressure is determined by flange and pipe/tubing rating.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

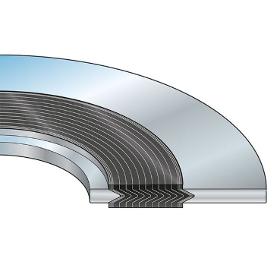

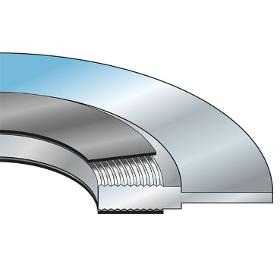

Spiral wound gasket made of crimped metal tape with sealing wraps of non asbestos gasket material. Optional: inner and/or outer metal ring. Characteristics For flange connections in high pressure pipe line construction and fittings Extremely low leakage with PTFE spiral. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance to 550 °C with graphite spiral Media resistance: pH 0 - 14 Max. pressure load: p = 400 bar Temperature range: t = -200 to +550 °C Technical parameters pH 0 - 14 Temperature: t = -200 … +550 °C Pressure: p = 400 bar Main application High temperature and high pressure flanges Piping Pressure vessels Heat exchangers Fittings Suitable for Power plants Petrochemical plants Chemical industry Material Centerring ring OD: Carbon Steel galvanized Spiral: 316L Centerring ring ID: Carbon Steel galvanized Other material combinations on request Product Types SF 11 Spiral wound gasket without any center ring for flanges with tongue and groove connection SF...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 5 Prophit High Temperature Gasket of Expanded Flexible Graphite with and without reinforcements Characteristics Temperature range in inert environment up to +3000 °C (attention: reinforcement inserts cause temp limits) Permanent elasticity, resilience approx. 10 % Non ageing - does not contain binding compounds High pressure resistance Radiation resistance and excellent media resistance Main application Flanges Sight glasses Valve bonnets Pipe flanges Suitable for Chemical industry Petrochemical refineries and steam production Pharmaceutical industry Power plant technology Paper industry Sugar industry Form of delivery Sheets or custom die cut rings With inner or/and outer crimp: mat. 1.4571 0.15 mm thick, seamless pressed Other materials and designs on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Universal ePTFE Gasket Tape HD with higher density Characteristics Very adaptive to surfaces Chemical resistance Simple to install Very high cross section sealability Wide area of applications Does not stick on flanges Easy to remove Universal sizes reduce stock keeping Material 100 % expanded PTFE Chemical resistant against all products with the exception of molten Alcalimetal and elementary Fluor Main application Pipe Columns Separation joints Mixer Pump Housing Machine Housing Glass- and Graphite-Devices Lined vessels Sight glasses Hand- and Manhole covers (Not TRD401) Ventilation and Air Condition Channels Steel and Plastic flanges Pipes and devices with highly aggressive chemicals Gearboxes Suitable for Pharma industry Food industry Approvals FDA21 CFR 177.1550 (PTFE), FDA21 CFR 170.105 (adhesive) EG 1935:2004 EU 10/2011 FDA Dimensions Dimension (mm) Gasket spool 10 m Gasket spool 25 m Gasket spool 50 m Seal area width 3 x 0.3 x x >3 mm 3 x 0.7 x x >3 mm 4 x 1.5 x x >15 mm

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Rectangular braided tube packing Characteristics The elasticity of this gasket tape allows low uneveness of the flange surface The sealant can be reused after opening of flange Low cold flow Sealing of the cutted ends by inserted point lock Main application Metal, glass, ceramic flanges on boilers centrifuges pipe flanges tanklid housings Suitable for Flanges in General service Variant SL 4 from ePTFE Graphite Fiber SL 6 from PTFE Fiber with oil SL 19 from dry PTFE Fiber SL 44 l from expanded Graphite, integrated Inconel reinforcement and adhesive backing SL 44l Dimensions 3 x 12 mm 5 x 19 mm 6,3 x 25 mm Other dimensions and basic materials – on request.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

D 7 ProCor Camprofile Gasket, Rip profiled metal base covered with graphite or PTFE, optional with or without center ring(s). 1] pay attention to the temperature limit of PTFE Characteristics For flange connections in high pressure piping and in fittings Extremely low leakage values with PTFE inlay. Helium leakproof 10 - 8 mbar l/(ms) High temperature resistance up to 550 °C with graphite inlay Technical parameters Covermaterial PTFE Temperature range: -200... +260 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 Covermaterial Graphit Temperature range: -200... +500 °C Surface pressure at 20 °C: min. 20 N/mm 2, max. 500 N/mm 2 Surface pressure at 300 °C 1]: min. 30 N/mm 2, max. 450 N/mm 2 1] pay attention to the temperature limit of PTFE Main application For all flanges inside the main traction line High level of temperature and pressure resistance Suitable for Power plants Petrochemical...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Universal fiber based high pressure gasket Characteristics A perfect selection of gasket material is based on operating conditions like pressure, temperature, media, surface pressure, Nonstick coating assures quick and scaling free disassembling Do not use any surface treatment! Technical parameters Temperature: t = -100 … +200 °C, short term up to 280 °C Pressure: p = 120 bar mainapplication Tube and pipe flanges Vessels Boilers Cylinders Joints Casings Lids Suitable for All Industries Approvals DVGW KTW BAM Form of delivery Sheets 1500 x 1500 mm in thickness of 0.5/0.8/1.0/1.5/2.0/3.0 mm or cut gaskets according to drawing or EN and international Standards Special dimensions and further gasket material styles from recognised manufacturers on request.

Request for a quote

SANHA GMBH & CO. KG

Germany

The installation system consists of high-quality NiroSan® Gas press fittings with yellow moulded sealing rings made of HNBR (hydrogenated nitrile butadiene rubber) and NiroSan® stainless steel system pipes according to EN 10312, DVGW-Arbeitsblatt GW 541 and EN 10312. All NiroSan® Gas press fittings are made of the material 1.4404 / AISI 316L (for moulded fittings) and 1.4408 (for threaded fittings and stainless steel precision castings). The material contains at a minimum of 2.3 % molybdenum and a lower carbon content than the conventional steel quality 316. Thereby these materials are not only of equal value but in addition, material 1.4404 / 316L stands out on account of its considerably higher corrosion resistance. The NiroSan® Gas press system is certified in accordance with and all important European certification bodies.

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Filling and mixing lines: Filling and mixing line, height and laterally adjustable Filling and mixing line, with removable mixing nozzle Mixing tube made of hard PVC, rotatable with 1 pipe clamp Filling and mixing line, galvanised steel, can be rotated using socket spanners, height and laterally adjustable mixing nozzle Mixing tube made of completely from hard PVC with flange connection with 1 pipe clamp Mixing tube made of completely from hard PVC with flange connection, height and laterally adjustable mixing nozzle with 1 pipe clamp Mixing unit completely galvanised, rotatable, height adjustable with clamp bracket and flange connection Mixing tube completely galvanised with flange connection, mixing nozzle, height and depth adjustable Mixing nozzle completely galvanised with flange connection, fixed mixing nozzle Tank filling line completely galvanised, fixed mounting, 360 degrees rotatable with flange connection Coupling parts,...

Request for a quote

ARMACELL GMBH

Germany

BESPOKE HIGH QUALITY METAL CLADDING WITH 40 YEARS OF EXPERIENCE Okabell is a rugged, non-combustible insulating system made of galvanised steel or aluminium for protection of damages of mechanical load. The Okabell system contains pipes, bends, flange and fitting caps, connecting pieces and front caps. The system is quick and easy to install. Standard material available on stock. Specified dimensions and types will be individual manufactured in short term.

BEULCO GMBH & CO. KG

Germany

Flange connector with loose insert pipe for optimum grip and durability. Our flange connectors are optimal for higher dimensions. They have an additional seal and a loose insert pipe. With our flange connectors for the application in water systems you are always on the safe side. The connector consists of various components, which can be assembled quick and simple without any special tool. The fixed insert pipe ensures an optimal form of the PE Pipe and stabilizes the pipe inwards, so the insert pipe holds up internal pressure. The additional seals ensure total security. The model is available in different versions. Pipe diameter: 63mm - 110mm Thread sizes: 2" - 4"

Request for a quoteResults for

Flange pipes - Import exportNumber of results

34 ProductsCountries

Company type