- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- finishing machines

Results for

Finishing machines - Import export

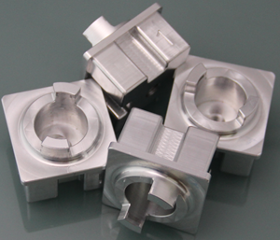

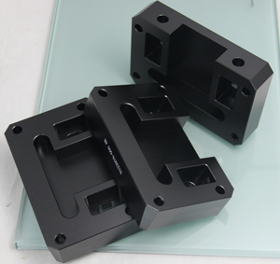

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical p

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining parts, CNC turning parts, CNC milling parts,Aluminium Housing, Flange, Valve Seat, Bush, Sleeve, Mechanical Parts for electronic devices,Mechanical Engineering Service, stamping parts, sheet metal parts, Cnc machining parts from China, Anodized Aluminium Milling part, Stainless Steel shaft, Titanium mechanical parts, Aluminium Enclosure, Aluminium turned lens in black anodize finish,stainless steel valve, copper machined plate, brass bush, brass sleeve, brass nut in nickel plated,copper screws, red anodized aluminium holder, blue anodized aluminium CNC milling plate, anodized mechanical parts, copper gold plating handle, zinc plated screws, custom made CNC turned part,ShenZhen mechanical parts supplier, critical cnc machining parts, precision mechanical parts, mechanical parts for camera, Stainless steel high polishing part, pump and valve mechanical accessories, Optic mechanical products, High quality precision machining parts, Nitrating steel shaft,machined mechanical

Request for a quote

MULTIVAC SEPP HAGGENMÜLLER SE & CO. KG

Germany

Our high-tech equipment starts with the meat tempering of the initial product up to the transfer of the finished portion to the packaging machine.

Request for a quote

ROCHOLL GMBH

Germany

We can offer a wide range of metal test specimens, starting from different grades of steel in various thicknesses and alloys right through to non-ferrous metals. Are you looking for galvanic finishing or machining solutions? Then you have come to the right place. Punching, deburring, and the rounding of corners are an important part of our portfolio. We will be happy to finish surfaces, for example by means of degreasing or sandblasting. Further finishing options are available upon request. We can also provide test panels with a customized serial number or marking if desired. Stainless steel 1.4301, 1.4571, 1.4401, 1.4310, other grades available upon request Test specimens According to A.F.E.R.A. 4001 (old standard), with defined finish With high-gloss finish (according to FINAT, PSTC standard, A.F.E.R.A. standard 5001, EN 1939) Titanium Grade 1 and grade 5, other grades available upon request Automotive grades painted

Request for a quote

WACHSFABRIK SEGEBERG GMBH

Germany

M-100 is a universal- fast cutting mixture of extremely fine and medium fine abrasive particles with outstanding polishing action. Formulated to simplify all normal buffing and mould preparation, and for maintenance and repairs of polyester and epoxy moulds. Recommended for removal of sanding marks and mould imperfections, a oneproduct-system, giving a deep gloss finish, also on finished parts for a final touch-up of hazy or dull finishes. For high temperature machine buffing. Contains no additives harmful to polyester gelcoats or epoxy surfaces. Does not contain silicones or waxes.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

The patented casting resin system ALWA MOULD D consists of two resin components and an aluminium filler. The fast curing of the material allows to produce your own technologically highest quality moulds in just a few hours. As our material is very good castable, compact moulds of any desired volume can be made from our product, such as acrylic baths, boats, etc. (<1 kg – 2500 kg). In comparison to other materials (e.g., glass fibre reinforced plastic), the system is more temperature-resistant, allows castings without air bubbles and does not have to be post-cured. Furthermore, the finished mould is easy machinable (e.g., drilling, milling, grinding, planning, sawing, turning, etc.). ALWA MOULD D moulds can be modified with repair filler, so that a fresh view can be created at an early stage of a new design process and prototypes can be examined at short notice.

Request for a quote

SAMSYS GMBH

Germany

With the MiJET part cleaning system it is possible to keep workplaces clean and workpieces hygienically cleaned with the simplest technology. An electrical connection is not necessary. Only a compressed air connection is required to use the device. Application The actual task of the MiJET is to filter oily air. Chips of the work pieces accumulate in the container. Operators often tend to blow off finished workpieces into the machine. This quickly results in dirty working environments and poor air in the production hall. However, we avoid this by exhausting these fumes. Oils are trapped from the exhaust air and chips and coolants accumulate in the container.

Request for a quote

SAMSYS GMBH

Germany

With the MiJET part cleaning system it is possible to keep workplaces clean and workpieces hygienically cleaned with the simplest technology. An electrical connection is not necessary. Only a compressed air connection is required to use the device. Application The actual task of the MiJET is to filter oily air. Chips of the work pieces accumulate in the container. Operators often tend to blow off finished workpieces into the machine. This quickly results in dirty working environments and poor air in the production hall. However, we avoid this by exhausting these fumes. Oils are trapped from the exhaust air and chips and coolants accumulate in the container.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

CUSTOMIZED SOLUTIONS READY TO USE! – The MFZ series offers endless solutions! INNOVATION THOUGHT THROUGH TO THE END! - Modularity in components takes you to the finish line. - Universal machine with 2, 3, or 4 spindles WHETHER DEALING WITH COMPLEX WORKPIECE DIMENSIONS OR IN SEARCH OF THE OPTIMAL QUANTITY SOLUTION WITH MINIMAL MACHINE INVESTMENT – We have consistently evolved our proven machine tool technology. - Extreme adaptability in dimension, material, accuracy, and capacity of your machining task DESIGNED IN THE PROVEN SAMAG CONSTRUCTION, BUT PERFECTED IN MANY DETAILS! – The modular design has significantly expanded the range of workpiece dimensions. - Unique modular system with optional width scaling and thereby correction possibilities in X-, Y-, and Z-direction LOWEST COST PER PART. – MFZ machines operate particularly efficiently, quickly, and dynamically. - Energy, lubricant, and compressed air consumption are significantly reduced

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik will meet even the most demanding customer requirements SCHMIDT Zerspanungstechnik sets high standards in terms of precision and quality when it comes to turning too: Our modern machinery includes various CNC lathes that boast the latest technology. The features of our high-precision machinery allows us as a machining specialist for large parts to produce work pieces with a swing of up to 1,100 mm and turning lengths of up to 4,500 mm and achieve the required surface finish with ease. Our lathes have roller burnishing and grinding tools so that your work pieces and semi-finished products can be individually customised to your specifications and special finishes realised. As a machining specialist for large parts, we rely on top quality and reliable processes when it comes to turning too.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

SCHMIDT Zerspanungstechnik will meet even the most demanding customer requirements SCHMIDT Zerspanungstechnik sets high standards in terms of precision and quality when it comes to turning too: Our modern machinery includes various CNC lathes that boast the latest technology. The features of our high-precision machinery allows us as a machining specialist for large parts to produce work pieces with a swing of up to 1,100 mm and turning lengths of up to 4,500 mm and achieve the required surface finish with ease. Our lathes have roller burnishing and grinding tools so that your work pieces and semi-finished products can be individually customised to your specifications and special finishes realised. As a machining specialist for large parts, we rely on top quality and reliable processes when it comes to turning too.

Request for a quote

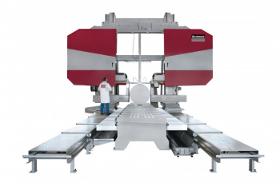

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

In forging mills, rolling and gravity die-casting foundries, and steel finishing works, these machines provide the ideal answer for dealing with large dimensions. They are perfect for preproduction in tool and mold making factories, helping to save valuable milling time. The material support table is recessed in the foundation. Its low-level transition to the hall floor makes for simpler material handling. The moving saw frame can be positioned by axis control precisely at the point of cutting. Where no sawing is taking place, the table is freely accessible. This also allows space for a second piece of material to be loaded while the saw is cutting. This system helps reduce downtime between cuts and enhances productivity. Benefits of the Gantry Machines - Space-saving installation - Durable material support table - Simple positioning of the saw frame - Optional: blade guide with 90° rotation facility for vertical and horizontal sawing to allow notching of materials

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

The planishing hammer GL 2 is the perfect tool to give the best possible surface finish on sheet metal parts already preformed. Even fine laser seams can be quickly and easily smoothed with the GL 2 planishing hammer. The ECKOLD GL 2 comes into play wherever sheet metal needs to be formed by hand. The GL 2 is used in car body repairs, vintage car restoration, appliances production, furniture design and even the arts and crafts sector. The planishing hammer is also extremely suitable to correct warpage after edging. The ECKOLD GL 2 planishing hammer is supplied with special inserts for planishing, stretching and curving. ECKOLD now offers special plastic inserts for forming without damage to the surface, and inserts with flexible shafts for better access to corners and edges. This GL 2 planishing hammer KIT 1 with a handy wall bracket, consisting of: Planishing hammer GL 2 Planishing insert steel Stretching insert steel Curving insert steel Order now!

Request for a quote

ECKOLD TECHNICS GMBH & CO. KG

Germany

The planishing hammer GL 2 is the perfect tool to give the best possible surface finish on sheet metal parts already preformed. Even fine laser seams can be quickly and easily smoothed with the GL 2 planishing hammer. The ECKOLD GL 2 comes into play wherever sheet metal needs to be formed by hand. The GL 2 is used in car body repairs, vintage car restoration, appliances production, furniture design and even the arts and crafts sector. The planishing hammer is also extremely suitable to correct warpage after edging. The ECKOLD GL 2 planishing hammer is supplied with special inserts for planishing, stretching and curving. ECKOLD now offers special plastic inserts for forming without damage to the surface, and inserts with flexible shafts for better access to corners and edges. This GL 2 planishing hammer KIT 3 with carrier case, consisting of: Planishing hammer GL 2 Various planishing, stretching + curving inserts steel + synthetic Order now!

Request for a quote

STRONG MAGNETS GMBH

Germany

Neodymium magnet (aka NdFeB magnet), is the third generation of rare earth magnet, which is composed of Neodymium, Iron, Boron and a few transition metals. With high remanence, high coercive force, high energy product, and high performance /cost, Neodymium magnet is currently the strongest magnet available in the world. Manufacturing Process Neodymium, Iron, Boron and a few transition metals will be mixed into the Neodymium powder, then fine Neodymium powder will be compacted in a die and sintered, fusing the powder in a solid state. There are two ways of pressing die pressing and isostatic pressing. Sintered parts normally need some finish machining in order to meet final tolerances. Machining & Tolerance Generally, Neodymium magnet must be machined using diamondgrinding techniques. Sometimes, machining operations may be performed on Neodymium materials with carbide tools, but surface finishes thus obtained may be less than optimal.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STARRAG GMBH

Germany

With the FOGS NEO series, Droop+Rein has developed a powerful machine concept for complex machining. The range of services covers processes from machining standard geometries and prefinishing contours to final finishing. For dynamic machining with the highest feed rates, the concept caters for the movement and acceleration of constant masses, regardless of workpiece size and weight. Dynamic and flexible With its new, highly flexible and fast Caxis (±400°), the Droop+Rein FOGS NEO highspeed machining centre is ideal for the complete multifunctional machining of very large workpieces. Of course, the series also features automatic pallet or tool change, tool diameter and length measurement and automatic billing of contour deviations. Thanks to a variety of components and peripheral devices from their modular system, Droop+Rein can create an efficient and processoriented overall system that is tailored to the customer.

Request for a quote

RHODIUS ABRASIVES GMBH

Germany

Non-woven disc drum, for use with satin finishing machines. • Consistent finishing • Long lifetime through high-density fill • Open structure, thus less clogging

RHODIUS ABRASIVES GMBH

Germany

Abrasive flap drum, for use with satin finishing machines. • Long lifetime through high-density fill • BW with slotted flaps for optimal workpiece adaptation

RHODIUS ABRASIVES GMBH

Germany

Felt flap drum, for use with satin finishing machines. • High-quality wool felt • Long lifetime through high-density fill • FBW with slotted flaps for optimal workpiece adaptation

RHODIUS ABRASIVES GMBH

Germany

Non-woven cleaning drum, for use on satin finishing machines for the removal of paints and rust. • Open structure, thus no clogging • High grain concentration for great cleaning performance • Manufactured from rings, therefore markedly longer lifetime

RHODIUS ABRASIVES GMBH

Germany

Drum, for use with satin finishing machines. Fill: combination of abrasive cloth and non-woven material. • Strong material abrasion with simultaneous surface finish • Long lifetime through high-density fill • Open structure, thus less clogging

TEST GMBH

Germany

Torsion testing machines by TesT are executed as horizontal machines with torsionally rigid machine bed. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

TEST GMBH

Germany

For measuring ranges up to 600 Nm Torsion testing machines by TesT are also available as vertical machines, equipped with T-slot table and height-adjustable drive. They are individually built as construction kit versions, always in accordance with customer demands. Thus, it is easily possible to incorporate individual preferences and specific customer requirements. Drive and control units, machine tables, frames and data acquisition will be integrated as finished components. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

THE EFFICIENT SOLUTION FOR SMALL PRODUCTION SERIESAre you looking for a solution that is a more economical choice than a larger Trowal system? Then look no further than our E5 mini barrel. It is perfect for deburring and abrasion, above all on small workpieces from the optical and fine mechanics industries. The double-conically shaped rotating barrel body generates an intense rotation to achieve the perfect abrasion result. SOPHISTICATED TECHNOLOGY The mini barrel stands on a steel sheet construction with four pedestals. The barrel bodies are secured to a drive roller and support roller with locking rings. The barrel body is made from polyurethane and the quick-action cap is waterproof. SPECIAL EQUIPMENT It is also possible to attach two additional barrel bodies if necessary. These are driven via a roller system that is fully variable thanks to a three-phase motor. The cover can also be ordered with safety switches.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

EXTREMELY GENTLE PROCESSINGRotating barrels offer a cost-effective and technically ideal solution, particularly when processing small parts in medium batches. This helps you get fine surfaces with neatly rounded workpiece edges, thanks also to the relatively long processing times. Trowal rotating barrels are also excellent for fine finishing and polishing. SOPHISTICATED TECHNOLOGY The barrel body is an octagonal, welded, biconal structure. It generates a triple sliding action in the mass of abrasive media with the workpieces to be processed. The lining consists of tear-proof rubber or PU, with the tight-sealing safety cover made of polyurethane. BARREL BODY WITH LIFTING AND LOWERING DEVICE The automatic lifting and lowering device lets you quickly feed and empty the barrel body. This is a major advantage, especially when processing times are short and when you are operating multiple rotating barrels.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

A HIGHLY EFFICIENT METHOD WITHOUT THE RISK OF WORK PIECES DAMAGING EACH OTHER Compared to standard mass finishing systems the newly developed M-TMD machine range finish high-value components 10 to 20 times more efficiently! By mounting the work pieces individually to workstations, which are part of a rotating carousel, you can process up to 18 work pieces in one single batch without risking part-on-part impingement. Different workstation angles - relative to their vertical position - allow the individual adaption of the machine parameters to your work pieces and guarantee absolutely stable finishing processes with excellent and repeatable results. APPLICATIONS: Orthopedic implants (medical engineering) Turbine blades (for airplanes as well stationary turbines) Precision components, for example, for pumps and compressors Work pieces made from tungsten carbide and other hard metals Fan wheels for turbo chargers (automotive industry) Sintered components, etc.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

INDIVIDUAL SOLUTIONSIf you are searching for a custom solution for your mass finishing processes, the TT...B series is the best choice. The modular system allows you to fit the individual machines with feeders, screening machines and abrasive media return transport systems as required. ELECTROMECHANICAL OR HYDRAULIC SYSTEMS AVAILABLE The work bowl can be pivoted either electromechanically (TT 25, TT 45) or hydraulically. You can also partially automate processing with the respective peripheral devices such as feeding and separating units. THE BENEFITS AT A GLANCE Individual mass finishing solution Modular system Choose from electromechanical or hydraulic system Partial automation possible

Request for a quoteResults for

Finishing machines - Import exportNumber of results

49 ProductsCountries

- Germany (49)

- Bonn, Düsseldorf and North Rhine and Westphalia (19)

- Hannover and Lower Saxony (2)

- Kiel and Schleswig-Holstein (2)

- Leipzig and Saxony (2)

- Mainz and Rheinland-Pfalz (8)

- Munich, Nuremberg and Bavaria (3)

- Saarbrücken and Saarland (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (11)

- Weimar and Thuringia (1)

Company type

Category

- Adjustment - machine tools (6)

- Finishing of surfaces - machinery (5)

- Milling - steels and metals (2)

- Machine tools, metal machining - parts and accessories (2)

- Environmental protection - machines and equipment (2)

- Grinding - steels and metals (2)

- Metallurgy - machinery and installations (2)

- Metalworking - portable power tools (2)

- Packing and packaging - machinery and equipment (1)

- Machine tools - metal machining (1)

- Mechanical surface treatment - machinery (1)

- Bicycle frames (1)

- Machine tools, metal shaping - parts and accessories (1)

- Magnets (1)

- Mechanical transmission - components (1)

- Medical and surgical optics - instruments (1)

- Nuts (1)

- Polishing equipment and materials (1)

- Precision engineering - portable power tools (1)

- Sawing machine tools (1)