- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filter papers

Results for

Filter papers - Import export

R&S PAPIERVERARBEITUNGS-GMBH

Germany

The paper dust filter bag has been produced by us for over 35 years for industrial and commercial cleaning. For cleaning e.g. offices, schools and similarly used rooms, it is still a cost-effective and environmentally conscious choice. Paper double layer, filter bags with dirt flap, plastic connection or sliding closure, paper dust filter bags also in set with motor protection filter

Request for a quote

BÜRKLE GMBH

Germany

The disposable powder funnel has a short, wide discharge and is suitable for transferring powered samples and materials, granulates ans suspension as well as other liquids. The wide opening of the disposable powder funnel prevents the powder or granulates from clogging while dispensing. That makes this practical and hygenic pouring aid a helpful accessory for sampling or in laboratories. In combination with a filter paper the disposable funnel is also well suited for filtering. The sturdy disposable funnel for powdered substances is ideal for use in laboratories and clean rooms or for sampling. It can be used in pharmaceuticals, chemistry and cosmetics and the food and animal feed industries, as well as all areas where special purity is important.

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple filter cartridges enables a large filtration area on limited space Low flow speed guarantees long filter life cycle Area of application For the filtration of coolants with minor impurities Applicable as protection filter For the filtration of oil, water, condensate, chemical products and fuels Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid with Filtration degree 3-5 µm Medium oil, emulsion and water Filter material stainless steel or paper

Request for a quoteFAUDI GMBH

Germany

Advantages Parallel alignment of multiple filter disks enable a large filtration area on limited space Low flow speed guarantees long filter life cycle Area of application For the filtration of coolants with minor impurities Applicable as protection filter For the filtration of oil, water, condensate, chemical products and fuels Flow rate Various filter sizes and the modular design enable any required flow rate. Classification number - Filter aid with Filtration degree 3-5 µm Medium oil, emulsion and water Filter material stainless steel or paper

Request for a quoteFAUDI GMBH

Germany

Advantages Large filtration area; high filtration capacity; long life-cycle Area of application For the filtration of aviation fuel as well as dehydration of oil and diesel Flow rate Various filter sizes and the modular design enable any required flow rate. classification number P45 Filter aid - Filtration degree 1 - 10 µm Medium Kerosene, hydrocarbon Filter material Coalescer elements, pleated paper

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used, partially overhauled three-spindle, horizontal machining center Product name: MFZ 2-3 Update Machine number 53152 Used 3-spindle horizontal 4-axis machining center Year of construction: 2009 The machine produced until October 2020 Sinumerik 840D Powerline control X-axis travel: 300 mm Y-axis travel: 500 mm Z axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z-axis 60000mm/min 3 motor milling spindles GMN, version with HSK63 tool holder Drive power (S1 / S6) 28 KW (constant) Torque (S1 / S6) 63/83 Nm Maximum speed 16,000 rpm Chip conveyor Knoll (scraper belt conveyor in the setting across the machine) Knoll coolant system with paper belt filter Flushing gun • Complete housing Tool storage (3 x 30 tools) Operating voltage 400V 3N ~ Control voltage 24V DC

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center – year of construction: 2007-2008 Product name: MFZ 2-3 Update Used 3-spindle horizontal 4-axis machining center Year of manufacture: 2007-2008 Painted in RAL1002 (sand yellow) or red-white Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (per machine without coolant system and accessories) X-axis travel: 300 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z axis 60,000 mm/min 3 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) Knoll KSS system with paper belt filter and magnetic separator Flush gun Complete enclosure Tool storage (3 x 30 tools)

Request for a quote

1-2-3 FILTER GMBH

Germany

The new pour-over coffee brewer consists of a stylish glass carafe and a unique funnel insert which provides an optimized bloom and flow of your coffee through the paper cone. Made in Germany with machine blown borosilicate glass for improved thermal properties,the BLOOM AND FLOW™carafe can be placed with liquid inside on a stove or over an open flame; it is also microwave-safe. The silicone collar is soft to the touch and is available in red or black, matching the colors of our coffee grinder. To keep your coffee warm, BLOOM ANDFLOW™ comes with a lid that replaces the funnel after brewing. Additionally, the finum® COFFEE WARMER matches the BLOOM AND FLOW™. 1. Choose a v-type paper cone suitablefor 2–5 cups of brew. For a perfect fit, fold the paper cone laterally and insert it into the funnel. 2. Pre-rinse the filter while inside the funnel. 3. Remove excess water after rinsing the filter. 4. Weigh out 10 g per cup (20–50 g).Ground should be coarse in size. 5. Add the ground...

Request for a quote

1-2-3 FILTER GMBH

Germany

Brown paper filters made from biodegradable cellulose. No glue or any type of binding agent. FSC certified – the most rigorous, credible forest certification system. Highlights fits cone shape No. 4 for ground coffee made of unbleached brown paper made without glue or any other type of binding agent Packaging 100 filters / box 10 boxes / master carton 1.440 boxes / pallet 3 languages (EN, DE, FR)

Request for a quote

1-2-3 FILTER GMBH

Germany

Brown paper filters made from biodegradable cellulose. No glue or any type of binding agent. FSC certified – the most rigorous, credible forest certification system. Highlights fits cone shape No. 2 for ground coffee made of unbleached brown paper made without glue or any other type of binding agent Packaging 100 filters / box 10 boxes / master carton 1.620 boxes / pallet 3 languages (EN, DE, FR)

Request for a quote

1-2-3 FILTER GMBH

Germany

The finum Clips are a clever option for closing and holding tea filters. Simply do the following: Open the Clip and place the filter into the clip. Close the clip by pressing it on both sides. Put the filter into the mug or cup and hang the Clip on the rim. After the tea has been brewed long enough, simply remove the Clip and dispose the filter. Highlights made from food-safe PP-plastic for placing at any pot, mug or cup / glass easy-to-use holder works with any filter size Packaging 1 Clip / sachet with eurohole 4 Clips / box 100 sachets / master carton 40 boxes / master carton 7.200 boxes / Palette 3 languages (EN, DE, FR)

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF RFB Return Line Filters are designed as tank top filters. They are mounted directly on the tank top and if 100% of the system oil is filtered they provide the optimum removal of contaminant from the system. This provides the pump with clean oil thus reducing contaminant generated wear. Because of it’s low weight and compact design, the STAUFF RFB Filters are ideally suited for mobile hydraulic applications. A high efficiency of contaminant removal is assured by using STAUFF RE Replacement Filter Elements. The high dirt-hold capacity of STAUFF Filter Elements ensures a long service life and as a result reduced maintenance costs. Valve (available as an option) ▪ Bypass valve Clogging Indicator (available as an option) ▪ Visual clogging indicator or electrical clogging switch Air Filter Element (available as an option) ▪ Filter paper micron rating 10 µm, other filter materials and micron ratings on request Filter Bowl with Threaded Connection (available as an option) Filter...

Request for a quote

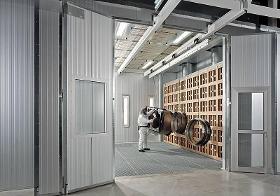

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

With high-quality filter tubes and PTFE diaphragms. Paint dust filters Wet painting also results in overspray. Overspray is the solid portion of the paint that is not taken up by the workpiece. According to the purpose of use, the overspray is moist and sticky immediately after release. It is captured by the exhaust air stream in the spray booth and fed to a filter. This can be, for example, a baffle plate filter, paper filter, fleece filter, glass fibre filter or also combinations of these. The adhesive effect causes the paint particles to adhere to the contact surfaces of the respective filter medium, as a result of which a good degree of separation is achieved. However, all these filters are storage filters, i.e. the filters clog up more and more during operation and cannot be regenerated. A filter exchange becomes necessary if the exhaust air rate of the spray booth falls below the minimum. This can be very time-consuming under certain circumstances and the work process must be interrupted in order to do it. To make things worse, not only must the filtered and bound paint residues be disposed of, but also the actual filter materials. Such tooling times are not justifiable for automatic, continuous or multi-layer painting processes. Continuous procedures such as automatically cleaned filters are likewise required for this. The humidity and the adhesiveness of the particles to be filtered are thereby the problem. In order to solve this problem, the paint particles should be relieved of their adhesive capability as far as possible whilst still inside the paint booth. Our patented ‘RTS-Rotation’ system is outstandingly well suited for this. The system is comprised of slowly rotating brush rollers, which take up the adhesive paint particles on the surface of the bristles and allow them to dry there. The bristles are automatically regenerated at pre-specified time intervals by combing devices that swing in at the rear of the brush rollers. The dislodged paint residues can then be removed and disposed of either manually during work breaks or automatically during operation. The degree of separation of this system is, however, insufficient to satisfy the environmental protection requirements concerning residual dust content in the exhaust air. A further filter stage is necessary for that. It must be assumed that the paint particles arriving here are to a certain extent still damp and sticky. For this we use special paint dust filters with high-quality filter tubes with PTFE diaphragms. If necessary, precoating agents (auxiliary dust) are used in order to neutralise the adhesive capability of the particles and to keep the dust layer on the filter elements permeable to air. The precoating agent is injected into the raw air pipe by means of special dosing units. The filter tubes are cleaned by means of compressed air impulse cleaning. The use of this technology requires special know-how. We have had the appropriate experience for almost ten years. The implemented plants have capacities ranging from 5,000 to 90,000 m³ /h. Because of the large number of different paint systems, individual experiments are usually necessary in our pilot plant in order to find the correct solution for the individual case.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

EXCOR KORROSIONSSCHUTZ-TECHNOLOGIEN UND -PRODUKTE GMBH

Germany

The EMIBO Nature VCI dispenser capsule consists of 100 percent natural raw materials. While the shell is made of tough cardboard, the VCI carrier inside the capsule consists of multi-layered technical filter paper. For faster VCI release and improved circulation, EMIBO Nature uses an innovative VCI chamber system. In addition to a rapid build-up of the VCI protective atmosphere, EMIBO Nature offers a reservoir of active ingredients that maintains its protective function even under extreme climatic conditions. As a handy accessory, the VCI dispenser made of pure cellulose is particularly suitable for one-way packaging. It is simply disposed of as waste paper.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Hybrid braid in W-Profile made of heat conductive ePTFE Yarn with Meta-Aramid fiber reinforcement and Run-In lubricant Characteristics Clean packing with ultimate heat conductivity for abrasive products in pumps and other rotating equipment. Recommended shaft surface hardness: HRC 35 Porosity filling coating increases density and protects the packing in crystallizing mediums. W-Profile Reinforcement reduces shaft wear Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 1 - 13 Density: 1.55 g/cm³ Main application Centrifugal pumps Mixer Agitators Kneader Filter Suitable for Pulp and paper industry Chemical industry Power plant technology Waste water technology Applications with abrasive products and when white packing is required Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbonized synthetic fiber with PTFE impregnation and run in lubricant Practical useful application data: max. temperature: +140 °C Characteristics Good flexibility Rot proof Form stable packing Good value for the money Recommended surface hardness HRC50 Operating range Pressure [p max]: 15 bar, Velocity [v max]: 15 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +200 °C pH: 3 - 12 Density: 1.30 g/cm³ Practical useful application data: max. temperature: +140 °C Main application Centrifugal pumps Mixer Kneader Agitators Refiner Autoclave Gate valves Filter Suitable for Pulp and paper industry Sugar industry Waste water technology General maintenance Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Synthetic Fiber Packing with PTFE Impregnation and Run-In Lubricant Characteristics Elastic and pliable Recommended shaft surface hardness: HRC 50 Resistance against rotting Structural stability Cost effective Operating range Pressure [p max]: 15 bar, Velocity [v max]: 12 m/s Pressure [p max]: 100 bar, Velocity [v max]: 1.5 m/s Temperature: t = -50… +140 °C pH: 3 - 12 Density: 1.30 g/cm³ Main application Centrifugal pumps Mixer Kneader Agitators Refiner Autoclave Gate valves Filter Suitable for Pulp and paper industry Sugar industry Waste water technology Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special length, pre-cut or die formed rings on request. 1 kg of packing of the following cross-sections corresponds to displayed meter lengths: Size mm["] Meter 4 48.1 5 [3/16"] 30.8 6 21.4 6.4 [1/4"] 19.1 8...

Request for a quote

SERIN GMBH

Germany

Testliner Fluting Offset Glassine Filter paper Siliconized paper LWC, SC

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH 2BE5 was developed from the proven NASH 2BE3 and 2BE4 compressors, whose reliable performance has been further improved. The development focused on optimizing performance, higher vacuum capabilities and ease of maintenance. NASH 2BE5 Benefits include: improved efficiency higher vacuum levels (to 100 mbar abs / 3" Hg abs) built-in ECO-FLO™ water saving technology with patent pending gas scavenging drop in replacement for 2BE3 and 2BE4 removable bearing brackets for easier maintenance elimination of tie rods, resulting in improved sealing due to bolted casing joints polyisoprene lining The footprint and connections to the NASH 2BE5 models are identical to its predecessors, the NASH 2BE3 and 2BE4. Therefore, exchanging or upgrading to the more efficient NASH 2BE5 requires no site modifications. The NASH 2BE5 model is available in cast iron, with stainless steel coming soon. The 2BE5 is perfect for use in mining, filter applications, paper mills, power plants, chemical plants, refineries and more.

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

The NASH 2BE5 was developed from the proven NASH 2BE3 and 2BE4 pumps, whose reliable performance has been further improved. The development focused on optimizing performance, higher vacuum capabilities and ease of maintenance. NASH 2BE5 Benefits include: improved efficiency higher vacuum levels (to 100 mbar abs / 3" Hg abs) built-in ECO-FLO™ water saving technology with patent pending gas scavenging drop in replacement for 2BE3 and 2BE4 removable bearing brackets for easier maintenance elimination of tie rods, resulting in improved sealing due to bolted casing joints polyisoprene lining The footprint and connections to the NASH 2BE5 models are identical to its predecessors, the NASH 2BE3 and 2BE4. Therefore, exchanging or upgrading to the more efficient NASH 2BE5 requires no site modifications. The NASH 2BE5 model is available in cast iron, with stainless steel coming soon. The 2BE5 is perfect for use in mining, filter applications, paper mills, power plants, chemical plants, refineries and more.

Request for a quote

CLEVERFILTER GMBH

Germany

SPECIFIC PRODUCTS FOR COARSE FILTRATION Top products of consistently high quality. For industrial applications and as designated pre-filters we classify filter cartridges, filter paper and standard filter bags into the following categories: WOUND FILTER CARTRIDGES • Wound depth filter cartridges for a wide range of applications thanks to their broad chemical compatibility • Numerous combinations of filter materials and dimensions MELT BLOWN FILTER CARTRIDGES • Melt blown polypropylene filter cartridges for nominal and absolute filtration • In all common lengths, materials and adaptations, with core or coreless FILTER PAPER / FILTER DISCS • Filter discs from cellulose and other materials • Different sizes and grammages FILTER BAGS • Sewn or welded single-layer standard filter bags • All common industry sizes as well as special sizes For more information about our Products:

Request for a quote

ASSFALG GMBH

Germany

The trough vibratory finishing machines are ideally suited for elongated individual parts and small series. Their advantages lie in the machining of heavy, bulky as well as long workpieces and in the contact-free working of sensitive individual parts in chambers. A soundproof cover reduces the noise level and makes working in a workshop possible. The clockwise and anti-clockwise rotation as well as the speed control from 1,200 to 1,500 rpm ensure a wide range of machining options. The unmanned working process is rounded off by the programmable timer. The system can be expanded with an optionally available paper filter and separator. For simple and convenient water treatment, we recommend a paper filter or a fully automatic water treatment system. The process water is pumped into the trough in doses and cleaned in the return flow via a filter fleece or the centrifugal force.

Request for a quote

ASSFALG GMBH

Germany

The tub vibratory finishing machine, which has a size similar to a washing machine, with a fill volume of 70 l is our standard machine and is ideal for prototypes and small series. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,500 to 3,000 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. The machine has a modular construction and can be expanded with an optional paper filter and separator. Both are controlled centrally through the control panel on the TV 95-SL. We recommend the PF440 paper filter for simple and comfortable water treatment. The S95 separator simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

The circular trough vibratory finishing machines are ideal for small and large series for different workpieces. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,200 to 1,500 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. We recommend a paper filter or a fully-automatic water treatment plant for simple and comfortable water treatment. The integrated separating equipment simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

The centrifugal plants are suitable for small parts. Due to the higher machining intensity with deburring, they deburr 10-20 times faster than vibratory finishing machines. The centrifugal plant can be planned as a single device up to a fully automatic plant. The grinding bodies and workpieces are accelerated through the rotational movement of the plate washer. Due to the centrifugal force, the workpieces are pressed outward and then transported up on the inner side of the system. Gravity causes these to fall back into the center of the plate washer to be accelerated again. A noise protection cover reduces the noise and makes it possible to work in a workshop. The speed regulation ensures versatile processing options. The programmable timer rounds off the autonomous work process. The machine can be expanded with an optional paper filter and separator.

Request for a quoteResults for

Filter papers - Import exportNumber of results

29 ProductsCountries

Company type

Category

- Finishing of surfaces - machinery (4)

- Mechanical engineering - custom work (2)

- Coffee machines, professional (1)

- Anti-corrosion products, chemical (1)

- Bottling and filling - machinery and equipment (1)

- Cigarette paper (1)

- Coated paper (1)

- Import-export - paper and cardboard (1)

- Vacuum cleaners - industrial (1)