- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling systems

Results for

Filling systems - Import export

MIROMATIC MASCHINENBAU GMBH

Germany

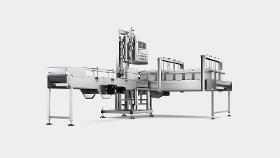

miromatic – With our experience, we offer you the perfect solution for your requirements. With our individually adaptable machine concepts, tailored to your product requirements, we can fill all fluid to paste-like products. 0.5 l – 30 l buckets Having specialised in tubs, miromatic is now the leading manufacturer in this segment. Bucket sizes from 0.5 l to 30 l can be filled with our systems and they are suitable for products with a great variety of different consistencies – even sticky products. Alongside our core area of competence – hygienic, low-germ and sterile filling, we also offer a broad spectrum of products in the non-food sector. 1.0 l – 25 l canisters Thanks to the experience that we have gathered in the hygienic filling of buckets, we are able to take the logical step of applying our expertise to other large containers. We are the first manufacturer to offer LOG3 category disinfection in the canister sector, whilst also achieving tremendous cycle rates.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

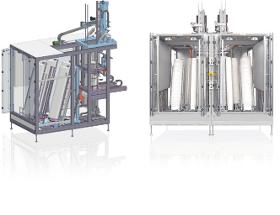

With fully automatic FRICKE filling systems buckets, canisters can be transported, filled, sealed and labeled. With the AFS 20 canisters can be filled directly on pallet fully automatically. Bunghole recognition carried out using camera technology. The AFS series offers you tried and tested single or double position fillers, the benefits of which are convincing at a glance. AIL FRICKE Systems guarantee you: ■ calibrated filling with high précision ■ fast and easy valve cleaning ■ simple one-man operation

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fully automatic filling system with automatic container turntable and integrated cap screwdriver for foaming, gassing or EX products, such as cleaning and care products, solvents, chemical liquids, mineral oils or glazes. For filling open bung hole containers, such as canisters. Undersurface filling coarse / fine, no dripping of the filling material. Product feed from higher storage tanks by gravity or with the help of pumps. Direct connection via product hoses at the valve. The facility offers you: ■ a nearly foam-free, calibratable underfilling ■ a quick cleaning of the valve (the product-contacting area consists of 3 parts) ■ a quick changeover to other container dimensions using format sets ■ easy operation by one person ■ compact, self-contained design.

Request for a quote

BIZERBA SE & CO. KG

Germany

The professional filling system FSL-PRO M for companies where to-the-gram weighing and safe packaging even of flammable, foaming or corrosive liquids as well as gentle dosing are of importance. This semi-automatic machine reliably fills your already palletized containers. With a multi-interval scale you also achieve exact weighing results for large measuring ranges. The professional filling system FSL-PRO M is specifically designed for companies filling large quantities. Canisters, pails and drums are equally suitable. For easy handling, the containers are filled and weighed while standing on a pallet. The FSL-PRO M with optional additive tare allows filling of all containers with a uniform small interval from the first to the last container.

Request for a quote

BIZERBA SE & CO. KG

Germany

Filling system FSL-ECO S is the optimal entry level model for small companies who want to fill high-quality, uncritical and non-flammable liquids. With automatic filling as accurate as 1 gram this practical system lets you save time and money. FSL-ECO S offers particular advantages for companies where filling of liquid products is a firm part but not the main task in their production process. This system is the first step from manual to automatic filling. The semi-automatic system safely and reliably fills all common containers such as canisters, pails, drums or IBCs. Products are handled manually and the automatic filling provides to-the-gram results. You avoid over or underfilling and save valuable time.

Request for a quote

BIZERBA SE & CO. KG

Germany

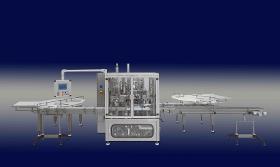

The fully automatic filling system optimizes your product quality by to-the-gram weighing, safe packaging even of flammable, foaming or corrosive liquids and through gentle dosing. By means of a multifunctional offset slide you benefit from maximum flexibility for container types and sizes as well as from efficient handling without retrofitting time. The fully automatic machine FSL-EVO S facilitates quick and reliable filling of high quality and sensitive products in different containers. Products can be fully automatically closed and labeled with variable data, if desired. By means of a set up buffer section the filling system largely works autonomously.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for filling liquids which froth, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. The machine offers you: ■ an almost froth-free, calibratable below Level filling ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 6 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Semi-automatic filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. The filling station has the following advantages: ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 12 enables complex control tasks, MES/ERP connections and remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line at any time, including automatic container conveying, capping and labelling. It is suitable for viscous to pasty liquids such as paints and varnishes and offers automatic container transport options as well as an electronic scale. The station supports coarse/fine over-level filling and can be connected directly to storage tanks via inclines or pumps. The system offers you: ■ a calibratable oversize filling system ■ quick cleaning of the valve (the area in contact with the product consists of 3 parts) ■ quick changeover to other container dimensions and changing products ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fully automatic filling system with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. detergents/cleaning and car products, solvents, chemical liquids, mineral oils, glazes. For filling open bunghole containers, e.g. canisters. Below level filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via gravity or with the help of pumps. Direct connection via product hoses to the valve. The system offers you: ■ an almost foam-free, calibratable below level filling ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the ideal solution for small and medium filling orders ■ simple operation by one person ■ Modular design enables extension by many automatic systems

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

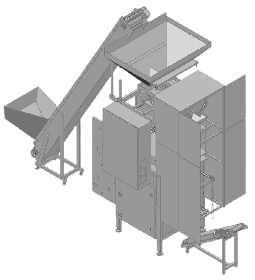

Challenger 100A is fully automatic vertical system designed for filling and packaging of food products (like frozen vegetable) in Nylon film

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

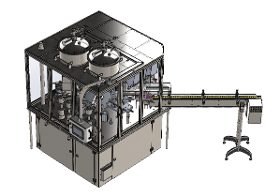

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

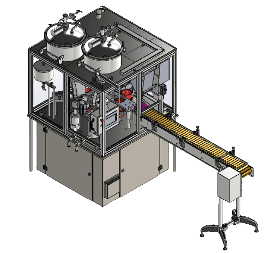

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers you suitable systems for filling and/or emptying tank trucks - both for dry bulk materials and for liquids. For this purpose, screw conveyors, pneumatic conveying systems or pumps are for instance used. We consider your individual requirements and build customised tank filling systems and tank emptying systems for you. We develop holistic solutions that are tailored to your requirements and can be integrated into the control of your production process with the appropriate sensor technology. This enables optimum functionality and operating safety.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers tailor-made plants and systems for the animal feed industry. Our mixing and dosing systems process both liquid and solid components, which are used for the production of animal feed, mineral feed and supplementary feed. To supplement our plant systems, we also offer adapted silo systems and tank systems as well as multifunctional filling systems and bagging or bottling systems for all types of containers. Our animal feed plants and systems are made of high-quality stainless steel and use food-grade materials and FDA-approved (Food and Drug Administration) components. Our focus is on hygiene and the diligence of the respective plant processes. The latest plant technologies guarantee the required degree of accuracy, economy and process reliability.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc (05/20/2021) White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing properties. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and for long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing behavior. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quote

BIZERBA SE & CO. KG

Germany

Mobile and flexible in combination with a fork-lift truck or forklift The verifiable load receptor iL Special 3000U/MP offers you a broad spectrum of weighing ranges: With its compact and practical U-shaped design it weights pallets ranging from 600 kg to 3,000 kg – also as dual interval. Combined with an iS weighing terminal the system reliably fulfills the functions weighing, counting or filling. Specifically for filling systems we are offering you a model with wider dimensions. Benefit with iL Special 3000/MP from time-saving processes, e.g. easy filling. The version with conveying unit allows mobile applications such as via pallet truck – back-friendly and without major physical effort. A battery pack makes you independent in terms of power supply.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

the economical alternative Replacement for STRATE 1DF2 and 2DF2 pump controllers suitable for connection to all STRATE fill level recording systems: contact-based or contactless the 2DF2 plus also handles dual level measurement: Sensor/pilot tube and sensor/contactor for outstanding operational reliability the current level and operating hours are always shown on the display

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

The TOPAZ Partfill is used, for example, in rainwater tanks or in tanks that should generally be filled as little as possible with city water. It ensures that in dry seasons the lowest required water level is automatically maintained with a partial fill. This allows the connected systems to continue operating while the tank has the maximum possible capacity for rainwater collection.

Request for a quote

ELKON GMBH

Germany

The cement stored in the cement silos can be quickly discharged to the cement trailers (bulk carrier) by means of ELKON telescopic cement loading bellow. This system has a special structure with support legs allowing the bulk carrier parking under the discharge point and is equipped with a suitable bellow for feeding the material. ELKON telescopic cement loading bellow is equipped with level indicator to stop loading and lift up the bellow when it is in contact with the cement (material filling process is finalized). The bellow is also equipped with fan filter system to prevent powder during the material filling process. The system includes a control panel as well.

Request for a quote

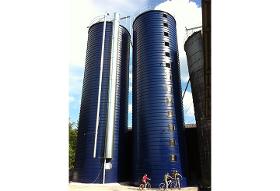

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Efficient on site production enables silos with a variable diameter to be installed quickly and cost effectively at the customer’s site. ACCESSORIES Modules prefabricated at the factory, e.g. filling and draining systems, can be installed and added. THOUSANDS OF PROJECTS REALISED WORLDWIDE The tried and tested LIPP system has been used to construct thousands of systems all over the world for more than 55 years. In particular, customers value the longevity of the tank solutions and the possibility of easily modifying them or fitting a wide variety of accessories during their service life. A selection of the projects carried out using LIPP bulk storage containers is shown below

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

We offer our customers a variety of technical accessories for the optimal handling and effective use of lubricants in your business. In addition to classic hand grease pumps, professional grease filling devices and pneumatic grease systems, our high-quality product portfolio also includes spare parts and workshop equipment for stationary operation. Our specialist advisors will support you in selecting the necessary accessories to make the handling of lubricants more effective.

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

Miromatic – Multiple stacks of tubs and lids can be stockpiled and automatically fed to the separating system, which cycles the tubs into the filling machine individually or places them on a conveyor belt. As a result, the machine operator does not need to re-load the packaging materials as frequently as a stockpiling time of up to 60 minutes is possible. Our systems are flexible and format-independent, from 0.5 kg to 12 kg.Your added value through miromatic stockpiling systems: Your operating personnel can be employed even more flexibly, because the system does not need to be permanently loaded with packaging materials. For one-track and two-track filling – filling possible during the production process Can be retrofitted to all miromatic filling systems Higher degree of automation and thus greater efficiency Lower workload for the machine operator Flexible system, aligned with your requirements Stockpiling of multiple stacks of tubs and lids

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling and closing machine for viscous products Machine performance: 60 cycles/min. max. 3 600 jars/h Special features: Dosing pump with motorised adjustment from 0-500 ml Heatable hopper with agitator Filling nozzle with recovery system (drip-free) Film applicator station (from film magazine or die) Sealing station (conductive system or induction sealing) Capping station

Request for a quoteResults for

Filling systems - Import exportNumber of results

93 ProductsCountries

Company type

Category

- Food industry - machinery and equipment (18)

- Bottling and filling - machinery and equipment (17)

- Packing and packaging - machinery and equipment (10)

- Gas extraction - systems and equipment (4)

- Automation - systems and equipment (3)

- Goods handling systems, continuous (3)

- Lubricants, industrial (3)

- Rolling mills - machinery and installations (3)

- Bag filling machinery and equipment (2)

- Measurement - Equipment & Instruments (2)

- Mechanical engineering - custom work (2)

- Sensors (2)

- Handling - Machines & Equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Concrete mixers (1)

- Construction machinery (1)

- Control boxes - electric (1)

- Fittings, metal (1)

- Paper, packaging - manufacture (1)

- Recycling - machines and installations (1)