- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling machines for liquid products

Results for

Filling machines for liquid products - Import export

FILLPACK GMBH & CO. KG

Germany

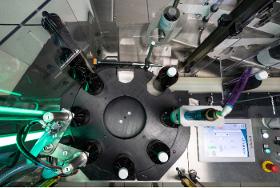

Filling machine for liquid through to viscous products, e.g. ketchup and mayonnaise Object carrier mode e.g. for plastic bottles Machine performance: 10 cycles/min. max. 80 bottles/min. max. 4 800 bottles/h Special features: 8 dosing pumps Immersed filling by programmable fill cams Fully-automatic cleaning

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling machine for liquids and viscous products, e.g. dairy products Tub and glass filling with 2 dosing pumps 5-lane machine Machine performance: 35 cycles/min. max. 4 000 tubs/h for liquids max. 6 000 tubs/h for paste products Special features: 2 dosing pumps with motorised individual adjustment from 0 – 500 ml Fully-automatic central lubrication Sterile air hood Transport plate for 3 formats

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling and sealing systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling - Filling station on the module trolley for a quick change and separate cleaning - Hot filling possible - Multi-component filling with different volumes is possible - Optimized filling process by spinning the container - Agitator systems for preventing product separation are optional Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Insertion nozzle movement/ dosing amount adjustment: freely programmable, adjustable intake and dosing time, adjustable return suction - Different dosing technologies are available - Volumetric dosing with auger filler

OPTIMA CONSUMER GMBH

Germany

- Compact construction - Product contacting parts can be made to customer specifications - Freely programmable filling nozzle movement and filling speed - CIP cleaning of product contacting components - Piston back space rinsing possible as option - Product feed via pressure vessel, pump, gravity or customer’s feeding system - Tool-free, operator friendly format change - In the case of leakages in the container or wet cleaning of the plant, no carryover through preceding transport system - Hot filling possible - Multi-component filling possible for diverse volumes

OPTIMA CONSUMER GMBH

Germany

The OPTIMA MPS is a modular machine specially designed for the packaging of food and chemicals. Liquids dossing or filling systems for powders can be integrated. The two-lane solution for stable, self supporting containers can flexibly fill liquid into formats ranging from cylindrical bottles to canisters. The mass flow filling system is installed on a mobile filling trolley, which allows quick product changeovers while reliably preventing cross-contamination. Additional functions such as handling processes, sealing, flushing, inspection and more can be integrated. The highly accessible system with explosion protection can also be equipped with a CIP unit.

Do you sell or make similar products?

Sign up to europages and have your products listed

OPTIMA CONSUMER GMBH

Germany

- Modular design: common dosing systems can be used - Diving nozzle movement / dosing volume settings: Freely programmable, adjustable suction and dosing time, adjustable drip retraction - Easy and quick cleaning, manually – CIP - Easy and quick format change - Small machine footprint

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling and sealing systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling - Multi-component filling with different volumes is possible - Optimized filling process by spinning the container - Agitator systems for preventing product separation are optional - Synchronization interface for the bottling plant - Adding booklets, leaflets, spoon/spatula or give-aways possible as an option Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Insertion nozzle movement/ dosing amount adjustment: freely programmable, adjustable intake and dosing time, adjustable return suction - Different dosing technologies are available Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-flexofill

OPTIMA CONSUMER GMBH

Germany

- Compact construction - Product contacting parts can be made to customer specifications - Freely programmable filling nozzle movement and filling speed - Fully automatic cleaning process (CIP) Standard - CIP/SIP possible as option - Product feed via pressure vessel, pump, gravity or customer’s feeding system - Maximization of performance through double track container transport with the same number of filling positions - Tool-free, operator friendly format change - Modular design: product guiding components completely exchangeable by means of module wagon simply and quickly (avoiding cross-contamination) - Vapor extraction possible - Explosion-proof execution optional - In the case of container leakages, wet cleaning of the machinery, there is no carryover into the machine sub-structure, due to welded seal, inclined machine cover - Hot filling possible - Multi-component filling possible for diverse volumes

LIQUID-UNIVERSUM GMBH

Germany

filling machines for liquids 550ml and 1001000ml (cbd oil, e liquid, desinfection, cosmetics, nutritions, vitamins)

Request for a quoteResults for

Filling machines for liquid products - Import exportNumber of results

10 ProductsCompany type