- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling and sealing machine

Results for

Filling and sealing machine - Import export

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2400 is a fully automated, linear motor driven, filling, foil application, foil sealing and capping machine, suitable for creamy to liquid filling media. Capacity: 35-40 pcs per minute Available versions: Fill/Seal, Fill/Cap, Seal/Cap, Fill/Seal/Cap machine frame from aluminium profile indexing transport system for jars horizontally working conveyor for jar infeed and discharge position control for jars in indexing rotary transport dosing pump from 1.4404 10 l hopper with level control filling nozzles driven by LinMot-e-motor pick and place system for pre-cut foils from magazines driven by LinMot-e-motor 1 spot sealer to fix the foil at the sealing rim of the jars sealing system with conduction sealing head capping station with LinMot-e-motor infeed conveyor for caps electric cabinet with operation panel manual central lubrication system safety doors with aluminium profile frame and windows from makrolon

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2400 is a fully automated, linear motor driven, filling, foil application, foil sealing and capping machine, suitable for creamy to liquid filling media. Capacity: 35-40 pcs per minute Available versions: Fill/Seal, Fill/Cap, Seal/Cap, Fill/Seal/Cap • machine frame from aluminium profile • indexing transport system for jars • horizontally working conveyor for jar infeed and discharge • position control for jars in indexing rotary transport • dosing pump from 1.4404 • 10 l hopper with level control • filling nozzles driven by LinMot-e-motor • pick and place system for pre-cut foils from magazines driven by LinMot-e-motor • 1 spot sealer to fix the foil at the sealing rim of the jars • sealing system with conduction sealing head • capping station with LinMot-e-motor • infeed conveyor for caps • electric cabinet with operation panel • manual central lubrication system • safety doors with aluminium profile frame and windows from makrolon

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

servo X Form Fill and Seal machines are available in five performance ranges and numerous variants. They cover the broadest possible range of horizontal film packaging applications for various industries – and all this with maximum modularity. The machines can be configured individually and thus meet all requirements for the desired performance or type of packaging. Depending on the machine variant, several packaging styles can be flexibly produced with one machine. Whether chain infeed or infeed conveyor, servo X machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The high-performance and extremely flexible intermittent Form Fill and Seal machine flexo H is particularly suitable for film packaging of wood and similar long parts from 800 mm in length, such as parquet or laminate, mouldings, wood or laminated wood, furniture parts or doors. It takes just five minutes to deal with a pallet of laminate. Similarly, our flexible packaging machines are ideal for similar length products, including skis and snowboards, spirit levels, rolled goods, steel pipes, and many more items.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent film packaging machine flexo 700 scores similarly to the basic modell flexo 500 with maximum versatility and flexibility, but is designed for the packaging of large format products with a width of up to 680 mm. Whether shoe boxes, boards, shelves, ladders, ironing tables, large calendars, pots, tissue rolls, insulating mats, etc., you are instantly equipped for any kind of large format application with this machine – daily changing orders, for example. The flexo 700 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films, dimensions and products.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The name says it all. The flexo 500 film packaging machine scores with maximum versatility and flexibility. Frozen pizzas, biscuits, fruit and vegetables, books, skis, laminates or various household goods, etc., you are instantly equipped for any kind of application with this machine – daily changing orders, for example. The flexo 500 features a side-sealing unit. The transversal sealing unit is designed as an intermittent version and processes a wide range of films, dimensions and products.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The servo X 800 are the most flexible and powerful of film packaging machines in the horizontal large-format segment – and all this with maximum modularity. They can be configured individually and thus meet all requirements. Whether chain infeed or infeed conveyor, servo X 800 machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

The intermittent Form Fill and Seal machines flexo 500/700 Push are pusher-machines that wrap difficult products with ease, such as glass bottles in bundles or salt and pepper shakers. They collect and group the products in order to subsequently push them into the film. In order to ensure that no products tilt over, our machines maintain physical contact with the articles to be packaged until they are safely in the bag. The transversal sealing unit is designed as an intermittent version and processes a wide range of films and product dimensions. The packaging style features a bottom overlap.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 20 form, fill and seal machine enables the production of bags made of polyethylene film from a flat film roll. The film can be neutral or coloured, with continuous printing or centred printing with print mark. The design of the machine and the low loading height allow ergonomic adaptation to a manual feeding station or easy connection to a feeding unit, such as an automatic counter, an automatic weighing system, an automatic assembly machine, an injection moulding machine, a conveyor belt or similar.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper haul-off timing belts are made with polyurethane or neoprene timing belts that are finished with many different kinds of coatings. They are used for conveying foils in bag forming, filling and sealing machines as well as numerous other conveying tasks. The extensive range of designs offers the optimal solution for any transport task and application, e.g. with smooth or vacuum-processed surface, finished according to individual specifications, and with many different coatings. Timing belts - Polyurethane molded timing belts - or neoprene molded timing belts Tension cords - Steel - Aramid - Polyester Coatings - PU yellow - Linatex - Various elastomers - Silicone

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Tecnimodern's slanted or vertical form fill and seal machines with very low loading height allow the production of polyethylene or polypropylene film bags from a flat film roll. The film can be neutral or coloured, with continuous printing or centred with print mark. These TEC30 packaging machines have the advantage that they can be equipped with either a thermal sealing system for heat-sealed films or an impulse sealing system for polyethylene films, depending on requirements. To meet the need for all types of packaging, feeding and product shapes, we offer various automatic feeding systems, such as: - Counting with vibrating or centrifugal trays - Weighing with linear scales - Dosing by augers or volumetric feeders

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

The TEC 06 form fill and seal machine uses standard polyethylene, biodegradable oxo sleeves or biodegradable sleeves (starch-based). The TEC 06 is particularly suitable for the production of display bags. The sealing head simultaneously performs the top seal of the pouch and the bottom seal of the next pouch, a cut is made between the two welds, and at the same time a pre-cut is made across one thickness of the sleeve to form a "kangaroo pocket" that allows the pouch to be filled. As this pocket is firmly connected to the spool, slippage is not possible, so that the weld seams subsequently run perfectly parallel. Due to the functionality and quality of its equipment, the TEC 06 is a very reliable machine that consumes few wearing parts.

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

Volumetric cup fillers enable the volumetric dosing of granular products. They can be fitted to all models of vertical form fill and seal machines and are offered in two series: 6 cups or 12 cups. Both models are equipped with a feed hopper with controlled outlet, a product level sensor, a series of cups made of food-grade material, a fixed lower cup carrier and, in automatic mode, a height-adjustable upper cup carrier with cup level sensor. The product is unloaded by gravity at the inlet of the packaging machine and, for fine products, the unloading system is equipped with a flap that prevents the product from spilling.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

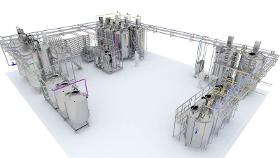

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2500 Variospeed is a fully automated filling, foil application and sealing machine, suitable for creamy to liquid filling media for plastic, tin or glass containers. Available performance versions: 2.500 units/h, 3.000 units/h or 3.500 units/h. all gearboxes are maintenance-free: Lenze main drive, Atek gearbox, Miksch stepping gear various cams on drive shafts of the gearbox: filling cam, control cam for valves, pre-sealing cam, lever arm for driving the metering pump and dispenser drive shafts with prockets for chain drives central lubricating system 8-up turntable with mechanical overload clutch backlog detector and monitor for incoming and outgoing containers filling unit with turntable metering unit 40 liters filling funnel dispenser with pre-sealing thermal sealing unit (conductive) integrated conveyor belt central, stepless height adjustment of conveyors and guides by a handwheel integrated SPS control system Siemens S7

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling and sealing machine – Autotwin → Filler and sealer stand next to each other Machine performance: 25 – 30 jars/min Special features: Film applicator station Sealing station (optional induction sealing system for glasses) Separate dosing unit

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling and sealing machine for viscous products Machine performance: 40 cycles/min. max. 2 400 jars/h Special features: Dosing pump with motorised adjustment from 0-500 ml Film applicator station Sealing station Capping station

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POLY-CLIP SYSTEM GMBH & CO. KG

Germany

Gain in efficiency – sealing and clipping with one machine The TSCA Automatic Sealing/Clipping Machine processes flat film from a roll into a ready-to-fill tube which is securely closed by the integral clipping unit. All commonly used films, coated or uncoated, as well as laminates can be processed. The film rolls used can be up to 3,000 metres long. Subject to technical modifications.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple gallon size, types and shapes Type of metal used S.S 316/304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Pneumomechanical Barrel feeding system Volumetric filling system One head Diving nozzles filling technology Servo conveyor system with multiple speed technology. Low to high viscosity Cut and seal system Multiple roll types can be handled. MechanicPneumatic capping system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, FDA. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION Compact Design. Cups feeder. Diving nozzles. Our machine can handle a large type of cups kind, size and shapes. CIP system. SPECIFICATION 3 filling heads. Servo star rotary system Type of metal used S.S 316 HMI and SCADA system with touch screen integrated user friendly and simplified software. Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple gallon size, types and shapes Type of metal used S.S 316 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION One gallon feeding turn table One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system. 4 heads filling nozzles Sealing and capping star section.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 2 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system UV sterilizer system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

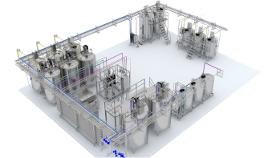

SPECIFICATION Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

CADA and HMI with a touch screen system Scrapers; PTFE food grade Teflon Pneumatic valve pneumatic system Cheese vacuum cooker machine; Double jacket, vacuum, pressure atmospheric system Compact design Capacity depends on the product type Cooker machine is equipped with an Electro pneumatic opening and closing system High homogenization system with steam injection valves Filtration system mechanical filter, to eliminating any unwanted residues. Sterilized Air pressure Transferring system. Buffer double jacket storage tank has been designed to maintain preserve and transfer the product to the filling machine Rotary filling sealing and capping machine sterilizing UV light integrated. Servo conveyor system Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

SCADA and HMI with a touch screen system Scrapers; PTFE food grade Teflon Pneumatic valve pneumatic system Cheese vacuum cooker machine; Double jacket, vacuum, pressure atmospheric system Compact design Capacity depends on the product type Cooker machine is equipped with an Electro pneumatic opening and closing system High homogenization system with steam injection valves Filtration system: mechanical filter, to eliminating any unwanted residues. Sterilized Air pressure Transferring system. Buffer double jacket storage tank: has been designed to maintain preserve and transfer the product to the filling machine Rotary filling sealing and capping machine: sterilizing UV light integrated. Servo conveyor system Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple product viscosity and types Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: Turnkey feature Milk Double jackets cooling collecting tanks Storage feeding tank Processing section Rotary bottles washing system Pasteurizer machines Homogenizer machine Rotary Milk, yogurt and cream cheese filling, sealing and capping machines Compact design Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

1,Specification •,Milk Double jackets cooling collecting tanks •,Chillers. •,Storage feeding tank •,Processing section •,Cheese press to mold machines •,Mozzarella cheese making machines •,Vacuum cooker cream cheese making machines •,Rotary bottles washing system •,Milk, yogurt and cheese filling, sealing and capping machines •,Fermentation room. •,Compact design •,Available certification up on your request UL, CE, GMP, FDA, ASME. •,Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. 2,Description ,High stability on high capacity. ,Can handle multiple ointment viscosity and types ,Type of metal used S.S 316 / 304 ,Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018

Request for a quoteResults for

Filling and sealing machine - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Food industry - machinery and equipment (9)

- Sealing and wrapping - machinery and equipment (6)

- Packing and packaging - machinery and equipment (4)

- Automation - systems and equipment (3)

- Custom packaging (3)

- Package stamping machinery (3)

- Rolling mills - machinery and installations (3)

- Food packaging (1)

- Dairies - machinery and equipment (1)

- Cheese-making machinery (1)

- Conveyor belts (1)

- Dosing - machines and equipment (1)

- Labelling machines (1)

- Weighing and dosing equipment (1)