- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling and packaging

Results for

Filling and packaging - Import export

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

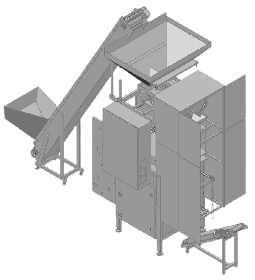

Challenger 100A is fully automatic vertical system designed for filling and packaging of food products (like frozen vegetable) in Nylon film

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

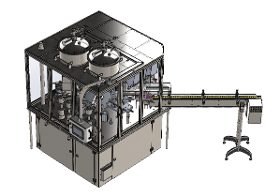

An automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five work stages that start with pulling the empty containers, then filling them, then placing the covers, then welding and taking out through the conveyor belt. It is suitable for high and medium production with a productivity of 3000 packages per hour.

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

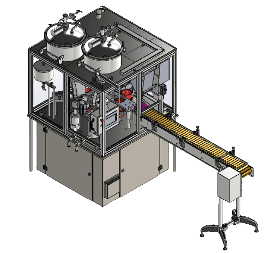

an automatic filling and packaging machine that operates in a circular system to fill liquid or semi-liquid materials with plastic containers of different sizes and shapes on demand. It consists of five stages of work, starting with pulling the empty containers, then filling them, then placing the aluminum or nylon cover, then welding with cutting and taking out through the conveyor belt. It is suitable for medium production with a productivity of 1500 packages per hour.

Request for a quote

JOSEF MACK GMBH & CO.KG

Germany

Our products are unseen aides installed in many electric machines and motors: from huge plants to compact hand-held devices. Are you looking for a entirely specialised solution for current and data transmission? We produce the right carbon brushes and brush holders for the broad range of applications which characterises the field of electrical and plant engineering. This includes filling and packaging machinery, waste water treatment plants or revolving door systems, just as much as the manual electrical appliances which provide professional and hobby craft workers with reliable service. And these are a just a few examples. As we are system suppliers, you can be absolutely sure: MACK supports you throughout the entire development process. MACK supplies first-class OEM quality and durable replacement parts from in-house production. MACK makes your ideas come true!

Request for a quote

WACHSFABRIK SEGEBERG GMBH

Germany

Disinfectant is the all-purpose agent when it comes to protection against bacteria, fungi and viruses. Disinfectants are most commonly found in doctors’ surgeries, clinics, as well as at home. It largely reduces the colonisation of germs on hands and surfaces, thus reducing the probability of infection by germs. The WFS offers you private label solutions for disinfectants: Alcohol-based hand disinfectants and alcohol-based surface disinfectants. In addition, WFS offers various services related to disinfectants, e.g. consulting, manufacturing, filling and packaging

Request for a quote

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

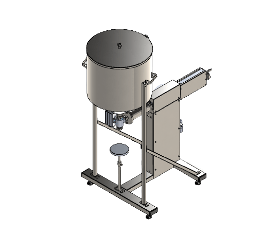

A semi-automatic filling machine for liquid or semi-liquid materials suitable for filling packages of any shape and size from 100 grams to 1000 grams, with a productivity of up to 800 packages per hour, suitable for small production.

Request for a quote

EK-PACK FOLIEN GMBH

Germany

MANUFACTURING PROCESS: » Blown-Coextrusion MAIN APPLICATION: » Lamination of multilayer films for hot filling applications » Modified Atmosphere Packaging FIELDS OF APPLICATION: » Food » Non-Food » Medical/Pharma FEATURES/PROPERTIES: » Very high O2- and CO2-barrier » High seal strength » High transparency » Various tintings possible » Asymmetrical layer structure » Modified sealing-layer especially for hot filling applications

Request for a quote

BIZERBA SE & CO. KG

Germany

Efficient control of packaging and label content in labeling lines The Bizerba LabelSecure vision inspection system automatically checks label position and texts. Bizerba LabelSecure can be integrated in conveyor lines with dynamic checkweighers. Thereby offering a high level of flexibility and adaptability to existing systems. Used with an inline dynamic checkweigher the system will add another level of protection on your production line. Consider the Dynamic checkweigher CWEmaxx. The system will checkweigh and reject any over filled and under filled packages. In addition, the vision inspection system performance is impressive, automatic control of label position, texts and film colour. Any packages that do not conform to the programmed or set criteria will be rejected. Also, package sizes and bar codes are verifiable. All packages that fall outside of the date range set up in the Vision Inspection System will be rejected, Ensuring out of date or short sell by dated products...

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Sealing lubrication of sliding surfaces, e.g. ground-in parts such as taper plugs, dosing plungers, valves, beer taps etc. Maintenance lubrication of plastic and rubber parts, as well as stuffing boxes, lip seals and O-rings Rolling and friction bearing lubrication in slow-running areas, toothing or chains on filling and packaging machines, stirring and grinding mechanisms etc. Advantages and benefits Highly effective due to proven lubricant formula Fulfils most demanding hygienic requirements. Reduced maintenance and lubricant costs due to possible long-term lubrication Resistant to hot and cold water, water vapour, wateryalkaline and acidic disinfectants and cleaning agents Neither hard residues result, nor is there a tendency to soften or drip due to pasteurisation or sterilization Odour and taste-free, and does not affect the properties of beer foam Toxicologically harmless as defined in German LFGB

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

For closed gear units and geared motors, plain and friction bearings even at higher rotating speeds, e.g. on filling and packaging machines For joints, propeller shafts and chains when grease lubrication is specified Advantages and benefits Toxicologically harmless as defined in German LFGB Formula in accordance the FDA guideline 21 CFR 178.3570 NSF H1 registered Long operating times due to good resistance to oxidation and ageing Reduced wear due to highly adhesive, load-bearing lubricating film Excellent corrosion protection Low dynamic viscosity enables use with minimal bearing play and gear unit spaces Good pumpability with central lubricating systems Very high resistance to hot and cold water, watery-alkaline and acidic disinfectants and cleaning agents

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Long-term lubrication of dirt-sensitive sliding points under vibration stresses Particularly suitable for lubricating chucks on tool machines Broad range of uses at stress-loaded parts, also at contact with cooling lubricants Lubrication of control and drive mechanisms Can be used at filling, labelling and packaging machines Advantages and benefits Resistant to water, steam and aqueous cooling lubricants Prevents frictional corrosion reliably Highly effective due to optimum solid lubricant combination Minimal consumption due to formation of highly effective lubricating films For optimum adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply sufficient paste evenly to the functional surfaces with a brush, spatula, etc. The paste will also act as a sealant. Do not use paste instead of grease and mix only with suitable lubricants.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

After every successful filling of a package, it is a basic condition for precise dosing that the thread is defined and breaks off cleanly. This effect usually occurs with water-like materials - with viscous products, so called semi-solids, but often not: Many products such as creams, gels and ointments pull long threads from the tip of the dispensing needle into the respective packaging. The ViscoTec Pharma Dispensers provide a solution: After a dosing shot of the Pharma Dispenser, the product path through the chambers in the rotor-stator system is blocked, thus preventing dripping of the dosing medium. A valve at the dosing needle or at the pump is not necessary. Thanks to the reversible direction of rotation, retraction can be set after the end of dosing: The material is drawn back into the dosing needle in a defined manner.

Request for a quote

GEBR. DÜRRBECK KUNSTSTOFFE GMBH

Germany

FFS film is an interesting alternative to ready-made plastic bags. Form fill seal film is perfect for packaging granulate, powder, grain, feed, wood pellets and more in one quick and easy step. FFS film manufactured by Dürrbeck meets the highest standards, guaranteeing the perfect protection against dust, moisture and other harmful elements. FFS film bags are easy to fill thanks to the power of gravity, and fulfil a variety of demands thanks to the many available options – including, for example, perforation or ventilation to allow moisture or air to escape from the bag, or a higher coefficient of friction (COF) that improves the stability of the load during transport.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber PickRobot stands for the uncompromising automation of slicing applications. Specifically adapted to your application area, it can be used flexibly for all insertion tasks and is available in five different executions: SmartPicker, single, double, triple or quad PickRobot. As powerful and highly efficient automation components with up to 230 picks per minute, the robots integrate perfectly into your line and ensure maximum performance. In combination with the Weber VMAX thermoforming technology, loading portions into an advancing index is possible, which maximizes performance even better than ever before. Advantages Flexible, reduced labor costs, and easy-to-clean Multi-variety and multi-layer packs available for compact spaces (overlapping, 90° rotation, variable portion shapes) Complete filling of the package when portions overlap Virtually eliminates human contact Improves food safety Handles all popular portion shapes and sizes

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Modular dosing system for filling conductive liquids in packaging machinery. Advantages over mechanical systems • no moving mechanical parts • easy cleaning in comparison with piston fillers • easy adjustment of batch quantities • no mechanical forces are applied to the product Special features • short dosing times of up to 100 ms possible • filling quantities from 1ml to DN 10 • small dimensions of the transmitter • wide range of batch quantity with one nominal size • CIP / SIP ability up to 140°C • min. conductivity >1µS/cm • complete system Flexibility • DN 10, 15, 20, 25, 32, 40 • various connections are available e.g.: • aseptic connection according to DIN 11864-1 to 3 • TRI-CLAMP according to DIN 32676 • milk thread according to DIN 11851 • 3A approved MDS completely electronic • different housing for 6/12/18 measuring channels • software for Linear, Rotary and Single Start Machines • connection to operator terminal or PLC • direct control of the dosing valve • 24 VDC...

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The focus is on intermittent sealing of top seals, e.g. of stand-up pouches, despite any product residues present. The vibration of the ultrasonic tool allows for obtaining reliable joint quality despite dusty or pasty filling contents. Burns caused to the packaging material during machine downtimes are safely prevented. The Herrmann SUP module is optimally suited for integration in new machinery or as retrofit in existing machine designs. Designing the module as IP67 variant, the top seal module is also suitable for wash down.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

With the docking station solution, your air cushion machine AirWave1/2 is able to show its performance. No volume is too large for rapid filling. Thanks to the fast and automated operation, the docking station will fill one container after another. Package contents: Mobile table (LxBxH: 50x50x121 cm) Rolling basket (LxBxH: 90x60x140 cm) Infrared sensor for the AirWave1/2

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

Gronemeyer lane bridging increases the accessibility of the various machines in a filling and packaging line. The gripper technology permits space-saving bridging of roads or pedestrian walks. Even large spans can be realised. Technical data: —Conveyor performance: up to 60,000 units/h —Crossing width: up to 6 m —Crossing height: up to 3 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain Optional equipment: —Moving deflecting pulleys in the curves to reduce wear on chains and slide rails —Motorized width adjustment —Complete machine cover made of Makrolon or steel grid with maintenance doors —Independent electrical control system with congestion monitoring —Loading and unloading belts

Request for a quote

WECKERLE MACHINES

Germany

Weckerle’s WP facilitates pouring and pressing of various wet cosmetic powders, such as eye shadows, blushes, and different kinds of face powder. Through the back injection technology and the direct filling into the packaging, the WP assures a maximum efficiency and saves further processing steps. WP Output: up to 3600 pcs/h Linear filling process

Request for a quote

WECKERLE MACHINES

Germany

Weckerle´s FlexFill facilitates to fill a wide range of cosmetic products such as mascara, lip gloss, liquid liner, deodorant sticks, nail polish, etc. Furthermore, this machine offers the possibility to fill into a variety of packaging with different volumes and diameters. Therefore, absolute process control and highest flexibility is ensured. Output: up to 10800 pcs/h Linear filling process

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

SAFE AND SUSTAINABLE – PELASPAN® BIO Developed by Storopack, PELASPAN® BIO is an exceptionally eco-friendly, pourable loose fill padding material. Our PELASPAN® BIO is certified in accordance with the DIN EN 13432 composting standard. The packaging chips are made entirely from cornstarch and can be disposed of with the normal household trash. Due to their tried-and-tested S-shape, the organic packaging peanuts interlock to create a coherent cushion that blocks, braces, and stabilizes your goods and prevents them from knocking against each other. They’re also odorless and attract next to no dust. The benefit of the PELASPAN® BIO packing material is that it automatically fills all the void in a package and as a result keeps your products safe even when exposed to heavy strain. The all-around cushioning consisting of organic packaging peanuts goes into the carton simply and quickly and can be easily integrated into any packing process. Using the intuitive packing material does not...

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

FAST AND PRECISE – FOAMplus® HAND PACKER FOAMplus® Hand Packer is the ideal solution for special challenges, including those posed by bulky and heavy packaged goods as well as products with complex contours. The handy foam gun allows you to accurately fill the carton with foam packaging in mere seconds – for customized blocking and bracing and the perfect transport of packaged goods. Foam pre-molded cushions can also be conveniently formed in advance with FOAMplus® Hand Packer. The microprocessor-controlled foam packaging system is extremely efficient, requires minimal maintenance thanks to the self-cleaning mixing chamber, and ensures seamless, cost-effective foam production in consistently high quality.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

LIGHTWEIGHT AND EFFICIENT – PAPERplus® CHEVRON PAPERplus® Chevron delivers maximum fill with less material. The unique paper cushion system produces crinkled paper tubes that are large in volume and offer exceptional shock absorption. Very little paper is required to fill void in the package, and will block and brace light to medium-weight shipping goods in the carton. The high-quality paper cushioning is flexible, malleable and, thanks to perforation, very easy to separate manually. PAPERplus® Chevron is available in a variety of versions, including free-standing and multiple tabletop models, and can be easily integrated into existing packing processes. Storopack customers can choose between brown and white kraft paper.

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-40

OPTIMA CONSUMER GMBH

Germany

Filling: - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product - Synchronization interface for the bottling plant - Vibrating the containers under the filling positions for product compaction and optimal utilization of the container's volume Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-fc2

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling and sealing systems coordinated to the product - Freely programmable filling nozzle movement and filling speed for below/over or bottom-up filling - Multi-component filling with different volumes is possible - Optimized filling process by spinning the container - Agitator systems for preventing product separation are optional - Synchronization interface for the bottling plant - Adding booklets, leaflets, spoon/spatula or give-aways possible as an option Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Insertion nozzle movement/ dosing amount adjustment: freely programmable, adjustable intake and dosing time, adjustable return suction - Different dosing technologies are available Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-flexofill

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-5

MÜLLER GMBH

Germany

All our drum lifters do not only handle your drums safely, they also meet GMP-standards. All lifting, inverting and swiveling columns work with electric motors which is very low noise level and operator friendly. For all different types of drums we can offer drum lifters with suitable pick up systems. The slim but stable mast offers the operator a safe visibility to the load. You can manage all handling operations like feeding of tablet presses, capsule filling machines, blister packaging machines, sieves or other transferring tasks with a Müller drum lifter. The lifting operation is always done by electric motor, all other operations like clamping, inverting and swiveling can be done either manually or by electric motors. Drum lifters from Müller are known for economic, save and ergonomic drum handling. Drum lifters with universal clamp lift / swivel / invert column Type FTHSK 300 G2 loads up to 300 kg column height 3.6 m Design: motorized lift manual grip, invert and swivel...

Request for a quote

HAVER NIAGARA GMBH

Germany

Price 87.400,00 € Condition Company Feige FILLING GmbH Location Bad Oldesloe Your Process Filling Category Package Drum Year built 2017 Contact person Martina Thomsen thomsen@feige.com 45318909341

Request for a quoteResults for

Filling and packaging - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Packing and packaging - machinery and equipment (4)

- Automation - systems and equipment (4)

- Silicones (3)

- Cosmetics industry - machinery and equipment (2)

- Cosmetics (1)

- Food Industry - Machines & Equipment (1)

- Conveyor belts (1)

- Films, plastic (1)

- Monitoring and control equipment (1)

- Pharmaceutical industry - machinery and equipment (1)

- Trolleys and trucks (1)