- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fastening tools

Results for

Fastening tools - Import export

ZEMO VERTRIEBS GMBH

Germany

Digital Power Tool Tester with Pulse Counter Management of tightening screws begins on checking fastening tools. YET testers are designed for high precision torque control of mainly impulse type tightening tools. Also usable for angle nutrunners, screw drivers, ratchet wrenches etc. However impact wrenches can be tested also, you should not exceed approx. 2/3 of the testers rated capacity. Install the YET torque tester in a tool maintenance shop, test laboratory, or at production lines for effective control of fastening such as acceptance inspection, periodical check and torque adjustment. YET torque testers feature a parallel centronics printer port and a serial RS-232C computer interface enabling simultaneous protocol as well as external data recording. Key Features: High accuracy within R.O. ± 0.5 % (stat. Load) Large digital display (LED) Measuring time can be set by every 0.1 sec within 9.9 sec. Shut-off time can be set 1-2-3 sec.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high-precision torque sensor can be used to perform both static and dynamic measurements on non-rotating parts. The internal and external square drive design make this sensor especially easy to fit in existing or new screw-fitting applications. Quality assurance and monitoring of screw-fastening tools are just two applications that can take full advantage of sensor features such as USB port, built-in amplifier and side-load absorbing bearings. With no rotating parts, this sensor needs no maintenance when used correctly. Available accessories include mounting brackets and flange adapters, which enable quick, easy and practical integration of the sensor into existing or newly developed setups and test benches. The strain-gauge based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Error Proofing Takes a Giant Leap Forward The Exacta Series of Radio Equipped Digital Torque Wrenches is the final piece in connecting all the torque application and data about every hand tool tightened fastener in your assembly. We have different Exacta digital wrenches to work with the Global Series of Process Monitors/Controllers. Learn more about how these nearly indestructible yet sophisticated torque application measuring tools can add value to your assemblies. The 1200 Series Exacta 2 Digital Torque Wrench has earned the reputation of being the hardest working, most accurate, reliable and durable digital wrench on the market. That reputation is built on much more than the ± 1% Indicated Value accuracy. The 1200 Series Exacta 2 pairs with the Global 400 and Global 400mp only. It does not communicate or pair with the Global 8. Note: The 1200 Series Exacta 2 Digital Torque Wrench is engineered to work with the radio in function mode. It will not perform without the radio...

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Rotary Transducer with Angle Measurement Option CheckStar sets the standard for dynamic torque and angle measurement of all continuous drive and impulse tools, with proven reliable performance in thousands of applications worldwide. CheckStar transducers fit in-line between the assembly tool and the fastener, measuring the actual torques applied under production conditions. Whatever the vibration and shock loads experienced, CheckStar's patented contact system ensures contact is always maintained between the readout and the strain gauges. Inferior systems suffer from "brush bounce" that leads to unreliable torque readings. The low inertia design of CheckStar ensures accurate and repeatable measurement of high speed transients, such as the point of shut-off on continuous drive tools and the pulsing of impulse tools.

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The CheckStar Multi is the latest generation of Crane Electronics market leading CheckStar in line rotary torque transducer. It raises the standard for dynamic torque and angle measurement of all continuous drive and impulse tools, with proven reliable performance in thousands of applications worldwide. If angle is specified, the CheckStar Multi rotary torque transducer will include an angle encoder giving 0.125° resolution (720 PPR). It also incorporates a light ring, giving the user visual feedback of the status of a tightening, when used with a Crane readout or data collector. The CheckStar Multi fits in line between the assembly tool and the fastener, measuring the actual torques applied and angular rotation of the fastener, under production conditions. Whatever the vibration and shock loads experienced, CheckStar Multi’s patented contact system ensures a connection is always maintained between the readout and the strain gauges. [...]

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SYSKOMP GMBH - EMICO

Germany

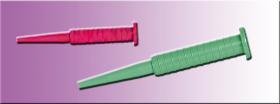

Convenient tool to fasten rivets, type 093. By using this tool the pin of the push rivet is mounted very reliably which speeds up the assembly time and avoids product failure. G = dimension G from series 093 Application: Attach the guide bushing on the rivet pin. Push the tool through completely. Thereby the pin is driven into the rivet.

Request for a quote

APEX TOOL GROUP GMBH

Germany

Compact, light, tough Cleco® updates the product range of pneumatic impact wrenches with a new mini compact model with 1/2" drive. The CV series is a universal impact wrench, designed for industrial production, repair and maintenance. Lightweight, balanced and with a comfortable design, the CV series provides fastening performance at an unbeatable value. All impact wrenches of the CV series are equipped with a powerful twin hammer mechanism. Also available in the common drive sizes 3⁄8-, ¾- and 1 inch. All advantages of the new Cleco® CV-375R-4 at a glance: - High-efficiency air motor - Twin hammer impact mechanism - Variable speed trigger - With ring anvil - No-charge modular muffler system - Max Applied Torque – 560 Nm - Max Breakaway Torque – 690 Nm - Free Speed – 8000 RPM - Lenght 157 mm - Weight 1,3 kg - Impacting Sound Level* 87 dB(A)

Request for a quote

APEX TOOL GROUP GMBH

Germany

The Apex µ-Guard line of Covered Drive Tools is the tool of choice for enhancing operator safety in almost all leading assembly plants. Apex® µ-Guard ™ free-spinning covered drive tools increase operator safety by significantly reducing or eliminating pinch points when operators are wearing gloves. Apex µ-Guard provides a protective barrier between genuine Apex fastener tools and your finely finished workpiece, thereby delivering the proven Apex performance plus the best protection available against in-system damage. The free-spinning design provides maximum protection for polished and highly sensitive surfaces. Apex has solutions for all aspects of safety on an assembly line when it comes to fastener drive tools. In addition to our line of Covered Bits, Bit Holders, Sockets, Extensions, and Universal Swivel Wrenches, as well as µ-Guard Gap Covers to eliminate the gap between a socket and an extension or between the right-angle power tool and a socket / extension.

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

Considerable reductions in time and money can be made by using LocTec® lock fasteners to create lock fastenings. The screw is simply screwed in using the special locking bit - job done. There's no need for any further locking measure - such as driving in steel balls, or using breakaway elements. The special flank geometry on the screw drive allows the screw only to penetrate inwards. Any attempt to drive it out, even using the locking bit that was used to fit it, will result in the fitting tool being automatically driven out. It means that the fastening can be undone only by mechanically adapting the screw head.

Request for a quoteResults for

Fastening tools - Import exportNumber of results

10 ProductsCountries