- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- externals clamping

Results for

Externals clamping - Import export

LEMM MASCHINENBAU GMBH

Germany

Hydraulic version Optional with external clamps for telescoping materials Capacity max. 2.500 kg The LEMM RWS reel turner is, of course, also available in special designs.

Request for a quote

LEMM MASCHINENBAU GMBH

Germany

Mechanical design Automatic load balancing Optional with external clamps for telescoping materials Capacity max. 150 / 250 kg The RWM-L reel turner allows for the problem-free changing of mandrels for various sleeve diameters.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Advantages Salient features and advantages of ELBO couplings: ➜ Modular type ➜ Torque transmission up to 1 300 kNm ➜ Standard shaft-hub connection designed as a keyway connection. Alternative types of connection like internally or externally clamping shrink disk connections available on request ➜ Compensation of axial, radial and angular displacements ➜ Coupling elements available in different stiffnesses ➜ Ease of assembly thanks to the plug-in axial design ➜ Low axial restoring forces due to the slide bearing ➜ Fail-safe ➜ Maintenance-free ➜ Suited for ambient temperatures from -40 °C to +80 °C ➜ Typical applications: Cableways, mills, crushers, large scale compressors

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,2 – 8,0 mm Outside diameter: > 120 mm after consultation All wire profiles feasible Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Clamping rings made of round wire or flat material Clamping rings with a stamp Rings with defined bendings Minimum burr cut-geometry Additional processing available after consultation Customer specific packaging Rapid prototyping

Request for a quote

TAS SCHÄFER GMBH

Germany

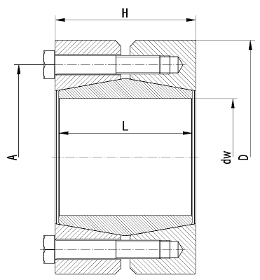

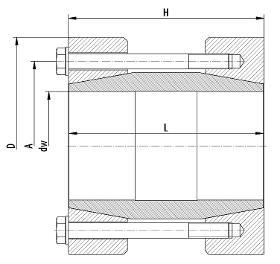

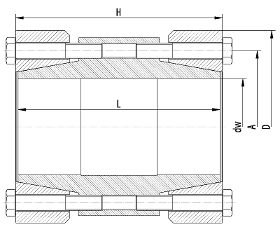

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. The external clamping system does not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean....

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quote

TAS SCHÄFER GMBH

Germany

The main function of the rigid shaft coupling is the safe and backlash-free connection of two shafts by means of friction. For example between a drive shaft and driven shaft and mainly to transmit torque. Shaft couplings consist of a connecting sleeve and two external clamping systems. They are not separable like flange coupling. The external clamping systems generate a backlash-free connection by pressing the connecting sleeve onto the shaft ends. They do not transmit any torque or moments between the shaft ends, they just provide the necessary clamping forces. Those external clamping systems are not part of the flow of forces, but the connecting sleeve is. The couplings have to be installed by moving them onto the shaft ends followed by tightening of the external clamping systems via bolting. To achieve proper operation and a sufficiently high coefficient of friction, the contact surfaces at the shaft extensions must be free of grease, dry and clean. Our rigid shaft couplings...

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-2/90 P=15 kW, n=1,500 RPM, M=500 Nm Construction principle: - Positioning and clamping: manual - SK 50 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1.68 : 1 - Manufactured length (up to spindle centre): 750 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-1/90 P=7 kW, n=3,500 RPM, M=150 Nm Construction principle: - Positioning and clamping: manual - SK 40 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 495 mm / 645 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description NC-single-axis positioning milling head KF-D2/90 P=13 kW, n=1,500 RPM, M=400 Nm Construction principle: - NC positioning lift-off milling head with hirth serration ring - Positioning the main spindle of the machine - SK 50 with automatic tool clamping - with external coolant supply - Lubrication: grease lubrication A-axis / Axis 2 (90°) - Swivel range: n x 360° - Pitch: 144 x 2.5° - Positioning accuracy: ± 3" - Tangential stress: 7,500 Nm Accuracy - Concentric running of the internal cone: L=15 mm : 0.010 mm L=315 mm : 0.030 mm - Centre offset : 0.020 mm

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

When turning outside diameters, it is necessary to consider which clamping system should be used and which components will be made most often. This is because if larger components are to be turned (and therefore with correspondingly greater depths of cut) a different system must be used than when turning smaller components with a finishing pass. Determining the cutting direction and tool holder A turning tool which works from right to left is called a right-hand turning tool because it machines the right-hand side of the work-piece (when looking at the tool point, the main cutting edge of the turning tool is on the right). View of internal and external turning Clamping systems The C Clamping System, P Clamping System, the M and S Clamping Systems. ISO Key image

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

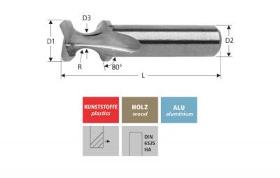

micrograin solid carbide external radius end mill: with double flute or up to four flutes, right-hand cutting, with specially cut edges for the machining of external edges, shank without clamping surface DIN 6535-HA

Request for a quote

MAGON HOCHLEISTUNGS-TOOLS GMBH

Germany

micrograin solid carbide external radius end mill: with double flute, right-hand cutting, with specially cut edges for the machining of external edges, shank without clamping surface DIN 6535-HA

Request for a quoteResults for

Externals clamping - Import exportNumber of results

14 ProductsCountries

Company type

Category