- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- environmental engineering

Results for

Environmental engineering - Import export

IFA TECHNOLOGY GMBH

Germany

As special plant constructors, we develop state-of-the-art environmental engineering plants. At the same time, we consider your individual requirements and build customised environmental engineering plants without losing sight of the economic aspects. We are also happy to support you with prototype plants or new technologies. Industrial processes are subject to increasingly stringent regulations and legal requirements. IFA Technology offers expert support in the field of environmental regulations, both in conceptual and constructive planning and in the manufacture of your plant components and plants.

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Environmental Technology / Mechanical and Plant Engineering / Renewable Energy Technology One-piece body, centric disc Also available as multi-blade version Operating temperatures up to 900°C, depending on material selection Flanged body according to DIN 24193 or customer specification Face-to-face length according to manufacturer’s standard or individual customer specifications Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: HVAC / Environmental Technology / Project Management and Engineering Design Capabilities One-piece body, centric disc Operating temperatures up to 900°C, depending on material selection Wafer type body for flanges according to DIN 24154 or DIN 12220 Face-to-face length according to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: HVAC / Environmental Technology / Project Management and Engineering Design Capabilities One-piece body, centric disc Operating temperatures up to 900°C, depending on material selection Flanged body according to DIN 24154 or DIN 12220 Face-to-face length according to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211

Request for a quote

SCHUBERT & SALZER CONTROL SYSTEMS GMBH

Germany

In contrast to other valve designs, only two diaphragm valve components come into contact with the operating media the diaphragm itself and the valve housing. The long service life, reliability, safety and resistance against aggressive and abrasive media, combined with the excellent control quality of the directly mounted digital positioner result in an ideal control valve with minimal maintenance effort and low operating costs. With its pneumatic actuator and proven Schubert & Salzer positioner, the diaphragm valve 7069 equipped with plastic housing is not only a true control valve alternative for applications in the fields of chemistry, cosmetics, environmental engineering and water treatment, it is also ideal for galvanising technology as well as for the food and beverage industry. A true all rounder.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KROHNE MESSTECHNIK GMBH

Germany

The OPTIBAR LC 1010 is a submersible level probe for water and wastewater, environmental engineering and OEM applications. It is particularly suitable for continuous hydrostatic level measurement in water wells, rainwater retention and overflow basins or tanks. The level transmitter features a robust stainless steel housing and a high overload-resistant ceramic diaphragm for long-term operation. The diaphragm is flush mounted for safe and easy cleaning on site. The level probe comes with pre-configured measuring ranges from 100 mbar / 1.5 psi to up to 10 bar / 150 psi. Customer-specific ranges are available on request. Its corrosion-resistant TPE cable is approved for use in potable water applications. The OPTIBAR LC 1010 features a 4…20 mA output and optional HART®7 for convenient configuration. The level probe can also be provided with an integrated Pt100 temperature sensor.

Request for a quote

DRIESEN + KERN GMBH

Germany

The DKRF417 humidity and temperature transducer ist the best choice for measurements at very high pressure levels. It is pressure-resistant up to 30 bar. Thanks to its small dimensions and M8 thread it is very well suited for applications within compressed air lines with small diameter. The probe’s operating range is 0...100% RH and it tolerates temporary condensation. It delivers highly accurate readings of up to 1.8%RH / 0.3°C. The DKRF417 humidity/temperature probe provides reliable readings even in challenging environmental conditions: · Compressed Air Systems · Engine Test Benches · Industrial Automation Technology We offer the compact, pressure-resistant transducer DKRF417 for relative humidity and temperature as well as the pressure-resistant humidity sensor EXT-D of the DKRF470 Series and the humidity and temperature Probe DKRF400.

Request for a quote

ERC ADDITIV GMBH

Germany

THE EFFECT Coke deposits on the injection jets lead to an increase fuel consumption. Corrosion particles (either in the diesel fuel or formed within the fuel system itself) can put the entire fuel system out of action. ERC System Cleaner for diesel engines cleans contaminated injection jets and helps to prevent residues and corrosion within the fuel system. THE ADVANTAGES AT A GLANCE - Cleans the injection pump and injection jets - Protects against deposits and corrosion - Ensures reduced fuel consumption as well as Environmental-friendly combustion - Restores full engine performance

Request for a quote

SUVIS GMBH

Germany

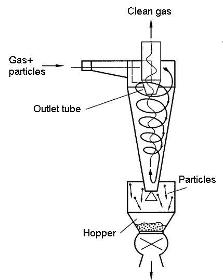

The gas cyclone belongs to the mostly applied technical separators, because it has applicationwise some fundamental advantages. One of them is certainly the fact that its construction does not show any movable components. For the large variety of different kinds of dispersed (particulate) phases (for example dust particles, metal chips, wooden waste, liquid droplets) and different gas conditions (pressure, temperature) the lay out and computation of a cyclone is still a complex task. Suvis has specialised in the development and lay out of cyclone separators and can offer professional solutions and consulting in the area of gas cyclones. Many years of experience gained through numerous cyclone development projects results in optimal solutions for our customers. A cyclone separator applies centrifugal forces and represents an effective apparatus for separating gas, liquid or solid particles from a continuous phase in chemical, process or environmental engineering.

Request for a quote

SUVIS GMBH

Germany

Another working area of the Suvis GmbH is the field of innovative sensor systems applied to particle and flow measurements taking into account microsystems. We develop novel flow and particle sensor systems for the application in environmental technology, process and mechanical engineering, and automotive technology. Important aspects are robustness and economicalness of the complete sensor system in order to create for the above mentioned application fields practical and affordable solutions. The respective sensor system will be developed as a whole solution. This means besides the hardware set up that we also take care of the evaluation of the sensor signals with our own solutions. We develop from scratch up to prototype level including periphery technology development. Please contact us for a not binding offer. We would like to know more about your challenge!

Request for a quoteResults for

Environmental engineering - Import exportNumber of results

11 ProductsCountries

Company type