- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- engineering plastics

Results for

Engineering plastics - Import export

POLYNEO GMBH

Germany

PolyNeo GmbH looks back on decades of experience in polymer trading. A high level of professionalism, both customer and supplier contacts that have developed over the years, in-depth market knowledge, strong cost awareness as well as the extensive technical know-how of our employees constitute the strengths of PolyNeo GmbH. For decades now, we have supported producers and customers all over the world by raw material sourcing, marketing and distribution as well as tailor-made logistics services.

Request for a quote

MICRO-EPSILON

Germany

The confocal chromatic confocalDT measuring system is used for fast distance and thickness measurements. Different sensor models and controller interfaces open versatile fields of application, e.g., in the semiconductor industry, glass industry, medical engineering and plastics production.

Request for a quote

SPIROL

Germany

Moulded-In Inserts are placed over core pins by an operator or a pick-and-place robot prior to the closure of the mould cavity during the plastic injection process. Moulded-In Inserts offer exceptional torque and pull-out resistance due to unrestricted plastic flow around the Insert body, and are often the Insert of choice for thermosets and engineered plastics with a high percentage of filler. The minor thread diameter tolerance is controlled to ensure positive positioning and perpendicularity of the Insert on the core pin during the moulding process. Series 63 is symmetrical eliminating orientation and Series 65 is the same body style in a blind ended version. SPIROL's Moulded-In Inserts are made from 2024 aluminium, a light-weight, lead-free grade. SPIROL’s Series 63 and Series 65 Moulded-In Aluminium Inserts are available in thread sizes ranging from M4 (8-32) up to M8 (5/16-18).

Request for a quote

SPANSET SECUTEX GMBH

Germany

Worm screws, gear wheels, slide rails and other technical mouldings are today made of engineering plastics such as POM (polyoxymethylene), PA (polyamide) or PE (polyethylene). These materials with different property profiles (negative high water absorption with PA, poorer wear behaviour with PE) are supplied as sheets or rods. The required moulded parts are then produced by mechanical processing (turning, milling etc.) in a more or less complex manner. Effective injection moulding is only worthwhile for large quantities together with small component sizes, otherwise the high tool costs cannot be amortized. secutexTechno is characterised by high hardness (70° Shore D) and rigidity over a wide temperature range. It retains its high toughness down to 30 °C, has a high abrasion resistance and a low coefficient of friction. The intrinsic colour is yellow, making it well suited for technical applications. Mechanical processing is simple and comparable with other hard plastics.

Request for a quote

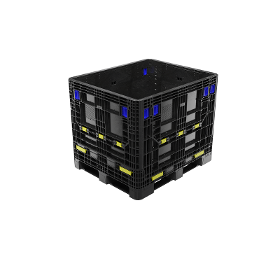

ORBIS EUROPE

Germany

ORBIS reusable bulk containers are designed to protect and transport heavy parts in automotive and industrial applications. Engineered for rugged applications, the plastic bulk containers are extremely robust and offer comprehensive product protection over a long service life. The 1200 x 1000 plastic bulk containers are available in multiple heights for increased packing density. The collapsible design with a return ratio of up to 1 : 3 reduces the shipping of air during return transport to a minimum. Key features: - manufactured from recycled material - multiple heights, access door and bottom configurations - durable all-plastic design - improved workplace safety - easy, on-site repair and part replacement - 100% recyclable

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WILH. KÄMPER GMBH U. CO KG

Germany

With over 125 years of market experience, a network of specialised companies has evolved to serve the wide range of your customers’ requirements with the best possible quality. The focus of these long-standing cooperations is on making the most of available know-how while maintaining fair market prices. Besides bent wire and plastic components, a wide range of industries also require so-called hybrid parts. This combination of metal and plastic is found, for instance, in screw joints, connecting rods, seat elements for lumbar support, and medical engineering, among other areas. We work in close cooperation with specialised partners for plastics engineering. Our great efficiency in wire working technology and plastic injection enables us to create hybrid parts that satisfy the most stringent requirements.

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Effectively reduce pneumatic equipment noise Engineered to provide an optimal balance between noise reduction and acceptable backpressure in the pneumatic system, our porous plastic silencers offer numerous advantages over metal acoustical silencers. Our porous plastic silencers are designed with a significantly lower weight along with greatly improved corrosion resistance and the ability to filter particles and aerosols. This leads to greater durability, assembly speed and cost-efficiency for our partners. Designed with a solid integrated threaded adapter to ensure easy mounting on pneumatic equipment, our silencers: Fit most standard valves – Offered in an extensive selection of sizes designed to fit most standard valves, including NPT, BSP, M5 and “push-in” styles. Enhance equipment longevity – Effectively filters particulates and aerosols. Reduce pneumatic equipment noise – Engineered with a porous plastic structure, offering greater noise reduction compared to metal and...

Request for a quote

SRK SOBERNHEIMER ROHSTOFF-KONTOR GMBH

Germany

Our recylcing machinery can process multiple types of thermoplastic polymers in diverse forms. Important is that the waste is clean, contains one polymer only and is thermoplastic. Our largest polymer is PVC. About 60% of the processed plastic waste is rigid or soft PVC. The reaming 30% are mainly PP and HDPE but also LDPE and multiple engineering grade polymers. The plastic waste can be mixed or single-colour (black, white, grey etc.). We buy plastic scrap of the following polymers: We can process many different types of plastic waste independent of form or size. Our recycling machinery enables a flexible recycling of solid, thin-walled and powdery plastic waste.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO can organize the production of your PEEK finished parts according to your drawing and material specifications. We are happy to advise you and rely on parts of our international network for productions of parts. Due to the integration of raw material sources (granulate and powder) up to the application technology we can recommend you the suitable processing of PEEK. PEEK finished parts can be produced for a variety of applications, for examples, compressor valve plates, fittings or screws. Finished parts can be produced by turning, injection molding, CNC machining or in the 3D printer.

Request for a quote

KLÄGER PLASTIK GMBH

Germany

Plug for medical engineering made of PA6 Plastic parts for machine engineering, medicine and other sectors

Request for a quote

BIEGLO GMBH

Germany

PAI material considers the most efficient fusible thermoplastic in terms of temperature resistance, chemical resistance and mechanical stress. Its mechanical strength at 205 °C surpasses many engineering plastics at room temperature. BIEGLO offers PAI finished parts of the following types: Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF). Each type is best suited for a particular application. Polyamide-imide can be used for a lot of appliations like gears, rollers, plasma chamber hardware and wafer contact fixtures. In addition, PAI material is ideal for high-temperature thermal insulators, burn-in test sockets, valve seats, fasteners, mechanical connections, rollers, labyrinth seals, drive wheels, valve plates, vanes and support gaskets.

Request for a quote

BIEGLO GMBH

Germany

Polyamide-imide (PAI), also known as the brand Torlon® comes in different grades and different shapes. PAI is known to be the highest performing meltable thermoplastic in terms of temperature resistance, chemical resistance and mechanical stress. BIEGLO offers PAI semi finished products, such as rods, tubes and sheets from different PAI types: Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF). Its mechanical strength at 205°C outperforms many engineering plastics at room temperature. The unique performance of Polyamide-imide (PAI) is the result of being transformed from a thermoplastic to a cross-linked thermoset during an extended curing process. Our PAI is processed by experienced engineers and offeres the best possible values a PAI product can have. It is suitable for many applications, such as gears, rollers, plasma chamber hardware and wafer contact fixtures.

Request for a quote

FRÄNKISCHE INDUSTRIAL PIPES GMBH & CO. KG

Germany

Fränkische Industrial Pipes perceives itself as an international partner for developing technical sophisticated corrugated tubes, tubing systems and cable protection tubes as well as fluid systems for the automotive sector, household appliances, machine engineering and apparatus engineering and also for the industrial sector. In the field of agricultural and construction machinery, our offer includes blow-moulded parts made of plastic, drainage systems, fuel line systems, air intake systems, air guidance systems, windscreen cleaning systems and various types of tubes. The tubes and appliances are occasionally being exposed to strains and ambient conditions. That is why FIP sets a high value on product quality for their customized tubing systems.

Request for a quote

HEXPOL TPE GMBH

Germany

Thermoplastic elastomers are bonded to engineering plastics by melt adhesion to the most widely used structural plastics. Since the materials are bonded together at the production stage, no separate adhesive is needed, which makes the process faster and more cost effective than if the two parts were assembled together after each had been produced separately. There are two main processing procedures used to achieve bonding, overmoulding and co-extrusion. When overmoulding with soft components, the surface of the hard component softens and a diffusion of the molecules in the outer layer takes place. A prerequisite for this is that the two materials, i.e. the TPE Compound and the engineering plastic, must be compatible with one another, meaning that they must not reject one another’s molecules. As the molecule mobility increases, the molecules of the two materials will diffuse and this gives rise to so called melt adhesion. The molecules of the two materials form a network at the surfac

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Efficient, accurate material drying is a crucial element in the processing of engineering plastics to ensure impeccable product quality. LUXOR CA A series compressed air dryers with ETA-process® and ETA plus® energy saving technology are specifically designed for supplying dried plastic granulate for many different plastics processing applications, with material throughputs up to 20 kg/h. Dryers can be mounted directly on the throat of the processing machine or on an adjacent support frame.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

Efficient, accurate material drying is a crucial element in the processing of engineering plastics to ensure impeccable product quality. The fully-insulated LUXOR CA S compressed air dryers provide a cost-effective solution for highly efficient continuous drying of all types of plastic granulate with material throughputs up to 25 kg/h. Dryers can be mounted directly on the throat of the processing machine or on an adjacent support frame.

Request for a quote

HEXPOL TPE GMBH

Germany

Overmoulding is a powerful technique that allows the production of finished parts in soft and hard material combinations without trimming or assembly. It offers many design and product advantages, allowing designers to differentiate products while meeting important user and patient demands, including soft-touch and cushioning for greater comfort and non-slip surfaces with improved grip for safety. The 500M Mediprene range bonds very well to polyolefins like polyethylene (PE) and polypropylene PP). However, in several medical applications transparent engineering plastics like ABS, PC, PETG and SMMA (and their blends) are utilised. The Mediprene A2 series has been developed to address demands for medical grade TPEs that bond well to these substrates. Special features Unfilled PVC, silicone & latex free 35 to 65 Shore A Flexibility over broad temperature range Resistant to many fluids used in the healthcare environment Sterilizable with gamma, EtO and steam Production site accredited

Request for a quoteResults for

Engineering plastics - Import exportNumber of results

33 ProductsCountries

Company type

Category

- Plain bearings (11)

- Additives for plastics industry (3)

- Plastics - machines and material for industry (2)

- Plastic products for engineering (1)

- Boxes, plastic (1)

- Chemicals - Basic Products & Derivatives (1)

- Coupling screws (1)

- Fittings, pipe, tube and hose - plastic (1)

- Hoses, pipes and tubes - plastic (1)

- Plastics - industrial raw materials (1)

- SMALL METAL PARTS (1)

- Screw cutting - steels and metals (1)

- Sensors (1)

- Tubs and vats, plastic (1)

- Vehicles - mechanical components and parts (1)