- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- energy technology

Results for

Energy technology - Import export

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik manufactures machines for many different industry sectors With our high-precision machinery and qualified employees, we fabricate custom machinery and plant equipment individually tailored to the needs of the particular industry. We act as dialogue and development partner for industry in the field of mechanical and plant engineering, and our service portfolio encompasses everything from consultancy and development work and implementing precisely tailored solutions to on-time assembly and installation on site. We design and develop machinery and plant equipment for our customers that need to meet very stringent requirements. SCHMIDT Zerspanungstechnik has a very high degree of vertical integration - something that has resulted in us becoming system partner in many branches of industry. We construct machinery and plant equipment for the following branches of industry: Steel processing Automotive Defence engineering Energy technology

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Industrial Combustion Technology / Renewable Energy Technology / Environmental Technology / Industrial Furnaces One-piece body, centric disc Operating temperatures up to 620°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length according to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Industrial Combustion Technology / Renewable Energy Technology / Environmental Technology / Industrial Furnaces One-piece body, centric disc Operating temperatures up to 800°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length according to manufacturer’s standard Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Environmental Technology / Mechanical and Plant Engineering / Renewable Energy Technology One-piece body, centric disc Also available as multi-blade version Operating temperatures up to 900°C, depending on material selection Flanged body according to DIN 24193 or customer specification Face-to-face length according to manufacturer’s standard or individual customer specifications Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Mechanical and Plant Engineering / Renewable Energy Technology / Shipbuilding One-piece body, centric disc Operating temperatures up to 800°C, depending on material selection Wafer type body for flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47 Face-to-face length according to manufacturer’s standard or individual customer specifications Mounting flange for actuators according to DIN EN ISO 5211 Inspection according to DIN EN 12266

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Steel Industry / Industrial Combustion Technology / Renewable Energy Technology One-piece body, tight-closing, centric disc Design for mounting between flanges according to DIN EN 1092-1 or ASME B16.5 Face-to-face length according to DIN EN 558-1-R20. Leakage rate A according to DIN EN 12266-1. permissible operating pressure 5 bar For all gases according to DVGW worksheet G 260 Safety shut-off valve according to EN161 class A (closing time < 1s)

Request for a quote

HERBERHOLZ GMBH

Germany

Applications:Steel Industry / Industrial Combustion Technology / Renewable Energy Technology One-piece body, tight-closing, centric disc With blow-out proof shaft Design for mounting between flanges according to DIN EN 1092-1 Face-to-face length according to DIN EN 558-1-R20 Leakage rate A according to DIN EN 12266-1 permissible operating pressure 10 bar, from DN 350 ≤ 1.5 bar For all flammable gases according to EN 437 and other neutral gases Safety shut-off valve according to EN161 class A (closing time < 1s) Approval according to DIN EN IEC 61511, up to and including SIL 3

Request for a quote

HERBERHOLZ GMBH

Germany

Applications: Steel Industry / Industrial Combustion Technology / Renewable Energy Technology One-piece body, tight-closing, centric disc With blow-out proof shaft Design for mounting between flanges according to DIN EN 1092-1 Face-to-face length according to DIN EN 558-1-R20 Leakage rate A according to DIN EN 12266-1 permissible operating pressure 10 bar, from DN 350 ≤ 1.5 bar For all flammable gases according to EN 437 and other neutral gases Approval according to DIN EN IEC 61511, up to and including SIL 3

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

60 Series Our medium-sized felt roller lubricators are designed for coil gauges up to 2 mm as well as viscosities up to 120 mm 2/sec (recommended guideline values). Fields of application Tool making: components for milling/turning/grinding machines Expanding metals for use in energy technology, chemistry, medicine Stamped parts for household appliances

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Piston Tube Technology Energy capacity 340 Nm/cycle Stroke 23.1 mm True performers: The combination the proven sealing technology from the MAGNUM series including membrane accumulator with the well-known piston tube technology from the SC² family makes the SC33 to 45 absorber models so strong and durable. The increase of the oil volume ensures the maximum braking forces. Short stroke lengths of 25 to 50 mm lead to shorter braking times in combination with a high energy absorption. These dampers safely and reliably decelerate rotary movements without unwanted recoil effects. Assembly close to the pivot point is possible. The low impact speeds with this are managed with ease by ACE's generation of piston tubes.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Piston Tube Technology Energy capacity 155 Nm/cycle Stroke 23.2 mm True performers: The combination the proven sealing technology from the MAGNUM series including membrane accumulator with the well-known piston tube technology from the SC² family makes the SC33 to 45 absorber models so strong and durable. The increase of the oil volume ensures the maximum braking forces. Short stroke lengths of 25 to 50 mm lead to shorter braking times in combination with a high energy absorption. These dampers safely and reliably decelerate rotary movements without unwanted recoil effects. Assembly close to the pivot point is possible. The low impact speeds with this are managed with ease by ACE's generation of piston tubes.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 1,870 Nm/cycle Stroke 48.6 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 370 Nm/cycle Stroke 23.1 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 170 Nm/cycle Stroke 23.2 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 1,870 Nm/cycle Stroke 48.6 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 370 Nm/cycle Stroke 23.1 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 170 Nm/cycle Stroke 23.2 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel Energy capacity 370 Nm/cycle Stroke 23.1 mm The latest damper technology in stainless steel: The self-compensating industrial shock absorbers MC33 to MC64 from the tried-and-tested and popular MAGNUM series is also available with all outer components made from stainless steel (material 1.4404). They are filled in the factory with special oil, which meets the permit conditions (NSF-H1) for the food industry. Just like the standard product family, the MAGNUM stainless steel models are distinguished by their robust, modern sealing technology, high energy absorption in a compact design, integrated positive stop and a wide damping range. Equipped with a PU head, they are available in thread sizes M33x1.5 to M64x2 with damping strokes up to 100 mm.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel Energy capacity 170 Nm/cycle Stroke 23.2 mm The latest damper technology in stainless steel: The self-compensating industrial shock absorbers MC33 to MC64 from the tried-and-tested and popular MAGNUM series is also available with all outer components made from stainless steel (material 1.4404). They are filled in the factory with special oil, which meets the permit conditions (NSF-H1) for the food industry. Just like the standard product family, the MAGNUM stainless steel models are distinguished by their robust, modern sealing technology, high energy absorption in a compact design, integrated positive stop and a wide damping range. Equipped with a PU head, they are available in thread sizes M33x1.5 to M64x2 with damping strokes up to 100 mm.

Request for a quote25-SC(2)190_FA_IMG_Single-01-cut-Labels_RGB-L_EN_36bb092b.jpg)

ACE STOSSDÄMPFER GMBH

Germany

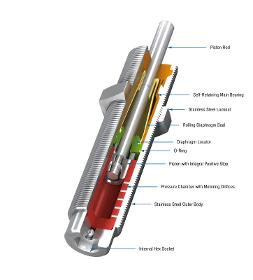

Self-Compensating, Piston Tube Technology Energy capacity 16 Nm/cycle Stroke 10 mm Soft damping, but enormous capacity: The range of 'soft contact' absorbers SC²25 to 190 extends from thread size M10 to M14 and covers effective weight ranges of 1 kg to 1,550 kg. All models are characterised by high energy absorption and they also unite the piston tube technology with the diaphragm seal perfected by ACE. This enables direct installation as end position damping in pneumatic cylinders at 5 to 7 bar or applications where deceleration needs to take placed close to the pivot point. They are maintenance-free, have an integrated positive stop and are mountable in any position. The option of a side load adapter allows impact angles of up to 25°. Thanks to their robust design and their durability, these miniature shock absorbers can be used for a wide range of applications. Designers mainly use them for pick and place systems, pneumatic rotary modules and in automation applications.

Request for a quote25-SC(2)190_FA_IMG_Single-01-cut-Labels_RGB-L_EN_36bb092b.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Piston Tube Technology Energy capacity 10 Nm/cycle Stroke 8 mm Soft damping, but enormous capacity: The range of 'soft contact' absorbers SC²25 to 190 extends from thread size M10 to M14 and covers effective weight ranges of 1 kg to 1,550 kg. All models are characterised by high energy absorption and they also unite the piston tube technology with the diaphragm seal perfected by ACE. This enables direct installation as end position damping in pneumatic cylinders at 5 to 7 bar or applications where deceleration needs to take placed close to the pivot point. They are maintenance-free, have an integrated positive stop and are mountable in any position. The option of a side load adapter allows impact angles of up to 25°. Thanks to their robust design and their durability, these miniature shock absorbers can be used for a wide range of applications. Designers mainly use them for pick and place systems, pneumatic rotary modules and in automation applications.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

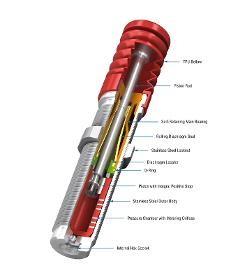

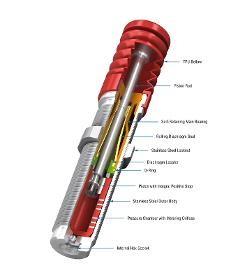

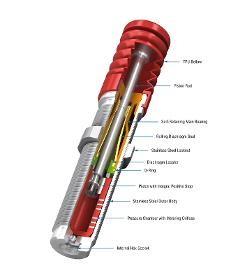

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 136 Nm/cycle Stroke 25.4 mm Hermetically sealed and rustproof: The Protection series PMCN is also available in a stainless steel design. This is or particular interest to the food and packaging industries. Their main special feature is the compact, totally sealed bellow between the body and the cap made of TPU (thermoplastic polyurethane). This protection safely encapsulates the ACE rolling diaphragm from the outside environment. Aggressive fluids don't stand a chance. The PMCN series is an excellent alternative if the accessory option of the SP type air bleed collar cannot be used due to a lack of compressed air. The PMCN series miniature shock absorbers, produced from stainless steel, are primarily suitable for use in the food industry, but are also wherever an elegant look is important e.g. in shipbuilding.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 41 Nm/cycle Stroke 12.5 mm Hermetically sealed and rustproof: The Protection series PMCN is also available in a stainless steel design. This is or particular interest to the food and packaging industries. Their main special feature is the compact, totally sealed bellow between the body and the cap made of TPU (thermoplastic polyurethane). This protection safely encapsulates the ACE rolling diaphragm from the outside environment. Aggressive fluids don't stand a chance. The PMCN series is an excellent alternative if the accessory option of the SP type air bleed collar cannot be used due to a lack of compressed air. The PMCN series miniature shock absorbers, produced from stainless steel, are primarily suitable for use in the food industry, but are also wherever an elegant look is important e.g. in shipbuilding.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 20 Nm/cycle Stroke 12.5 mm Hermetically sealed and rustproof: The Protection series PMCN is also available in a stainless steel design. This is or particular interest to the food and packaging industries. Their main special feature is the compact, totally sealed bellow between the body and the cap made of TPU (thermoplastic polyurethane). This protection safely encapsulates the ACE rolling diaphragm from the outside environment. Aggressive fluids don't stand a chance. The PMCN series is an excellent alternative if the accessory option of the SP type air bleed collar cannot be used due to a lack of compressed air. The PMCN series miniature shock absorbers, produced from stainless steel, are primarily suitable for use in the food industry, but are also wherever an elegant look is important e.g. in shipbuilding.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 136 Nm/cycle Stroke 25.4 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 41 Nm/cycle Stroke 12.5 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 20 Nm/cycle Stroke 12.5 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

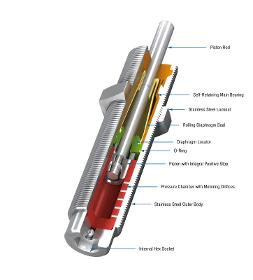

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 136 Nm/cycle Stroke 25.4 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Stainless Steel, Rolling Diaphragm Technology Energy capacity 41 Nm/cycle Stroke 12.5 mm Brilliant in every respect: These high performance miniature shock absorbers in stainless steel are based on the MC150 to MC600 product family and its proven damping technology. This means that these special absorbers offer all of the benefits of the MC standard units such as the proven ACE rolling diaphragm technology for maximum service life and direct installation in a pressure chamber with up to approx. 7 bar. Thanks to perfectly progressive maximum energy absorption and effective weight potential, their use is augmented even further by the outer body and a complete range of accessories made of stainless steel (material 1.4404). Miniature shock absorbers made of stainless steel are mainly used in medical and electro-technology, but also in shipbuilding, packaging and chemicals industry and in the food processing. For the latter, they are filled with a special oil in...

Request for a quoteResults for

Energy technology - Import exportNumber of results

57 ProductsCountries

Company type

Category

- Metallurgy and iron and steel industry - machinery and installations (7)

- Lighting, street, industrial and commercial (3)

- Plastics - machines and material for industry (3)

- Milling - steels and metals (2)

- Automation - systems and equipment (1)

- Cabinetmaking - machinery and equipment (1)

- Cleaning machines, industrial (1)

- Electrical & Electronic Components (1)

- Electricity - production and distribution (1)

- Electronic data processing - microcomputers (1)

- Glass (1)

- Power Stations (1)

- Precision engineering - portable power tools (1)

- Rolling machines (1)

- Shot blasting - steels and metals (1)

- Tanks, metal (1)

- Valves for industrial fittings (1)