- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- dynamic balancing

Results for

Dynamic balancing - Import export

LLOYD DYNAMOWERKE GMBH

Germany

From the project planning stage through to the end of their operating life we offer a range of concepts for economical and fault-free operation of your machines Target-oriented maintenance intervals to match the respective operating conditions Online and offline status monitoring Trend measurements relating to wear behaviour of the mechanical and electrical components Stocking spare parts for shorter downtimes Training for maintenance staff 24 hour service Company-oriented maintenance contracts Modernisation of the machine, controllers and protection equipment Environmentally compatible recyclingTesting of electrical machines and systems, type tests, system tests, heat run tests according to DIN standards Dynamic balancing or rotors Cleaning and oven drying of large machine parts such as stators or rotors VPI impregnation with rotating hardening process in drying oven VPI impregnation of transformers and large coils VPI or resin-rich coil production Manufacture of tooth-wound coils

Request for a quote

KULLEN-KOTI GMBH

Germany

A further variation of the "Throw-Away" system is type 230. It consists of continuously wound DBS-spiral brushes fitted to a thin walled steel, stainless steel or non-ferrous metal tubular shaft. The face width corresponds to the required total brush legth (BLG). The complete "Throw-Away" brushes can be simply assembled onto the customer's existing shaft. This method avoids the costly return of the complete shafts when the brushes have to be replaced. Core systems The complete "Throw-away" brushes type 230 can be supplied with adaptors to reduce the core inside diameter (KD) i. e. brushes with or without collar with suitable arbor holes (AL) for the different core systems WK1 and WK2. Our roller brushes are supplied with a fill surface perfectly trimmed and/or ground for concentricity. The brushes with adaptor or bushes are electro-dynamically balanced at the intended rotation speed according to standard G 2.5 as per ISO 1940

Request for a quote

KAMAT GMBH & CO. KG

Germany

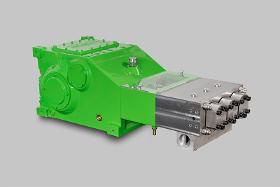

The K18000-3G triplex plunger pump has forced lubrication, making it ideal for continuous operation. Its main application is industrial cleaning. For large ship areas it is advisable to combine the pump with the Magnet Crawler (Ship Hull Crawler) from the Gekko range. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature. - Minimum inlet pressures dependent on fluid being pumped - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Forced lubrication gearbox (> 130 kW with oil cooler) - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Can also be operated vertically - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

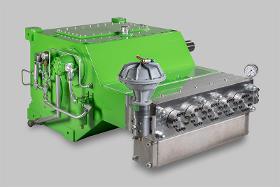

K25000-3G high-pressure triplex plunger pump for 24/7 operation, pipeline tensioning and leak testing of tanks and various pipelines. The K25000-3G is used internationally hundreds of times as a high-pressure pump in hydraulic face construction. With a power of 250 kW, a gearbox with forced lubrication and an optional oil cooler, the pump is perfectly suited to the demands of 24/7 mining operations. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod load - Dynamically balanced gearbox - Forced lubrication gearbox (> 160 kW with oil cooler) - Standard gear ratios i = 3.33 - 3.50 - 4.04 - 4.62 - 5.44 - Can also be operated vertically - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

With 110 kW, the K11000-3G high-pressure pump is a powerful plunger pump that is mostly used in intermittent operation. The reason for this is that this KAMAT high pressure pump has splash lubrication and not oil pressure lubrication. This makes the pump more suitable for intermittent operation, but it is extremely robust and can therefore be used in continuous operation even at 110 kW. Classic applications for this pump are industrial cleaning, blasting and process engineering. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Splash lubricated gearbox - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils etc. on request, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

Working at high pressure and high volume flow with the KAMAT Triplex plunger pump K45000-3G: particularly suitable for pressure tests of containers, pipeline stressing and pipeline testing. The K45000-3G focuses on hydraulic applications and jetting. In jetting, the 450 kW high-pressure plunger pump is often installed in large mobile systems. The K45000-3G plunger pump is particularly suitable when high litre capacities are to be realised at high pressure. SPECIAL FEATURES - Flow rates with 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Forced lubrication gearbox with oil cooler - Standard gear ratios: i = 3.39 - 4.05 - 4.76 - 5.25 - Also available according to API 674, can also be operated vertically - Special media such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

Extremely high flow rates with the UHD K150000-5G quintuplex plunger pump - ideal for fracking and descaling. With a maximum drive power of 1500 kW, the K150000-5G high pressure pump is an extremely powerful high pressure pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows large volume flows without cavitation in the pump. Special Features: Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 0-100% depending on rod force dynamically balanced crankshaft Gearbox with external forced lubrication and oil cooling External gear ratios on request e.g. i = 4.76; 5.72; 6.3 Also available to API 674 Horizontal operation Special fluids such as seawater, glycol, methanol, oils, etc. on request.

Request for a quote

KAMAT GMBH & CO. KG

Germany

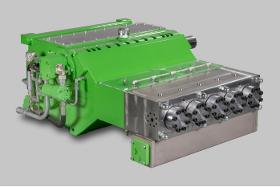

Pumps without upstream pressure: The Quintuplex K55000-5G plunger pump as a 550 kW high-pressure pump with five cylinders for direct as well as indirect hydromechanical descaling, mining and concrete rehabilitation. With five cylinders, the K55000-5G is one of our extremely powerful high-pressure pumps. Its special feature is that it has five cylinders that are precisely calculated and matched to each other: Thus, the K55000-5G achieves high performance without cavitation and with very low residual pulsation. It is even capable of pumping up to 640 l/min without upstream pressure. SPECIAL FEATURES Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force Gear dynamically balanced Gearbox with forced lubrication and oil cooling gear ratios i = 3.30 - 3.95 - 4.66 - 5.63 Also available to API 674, including vertical operation Special fluids such as seawater, glycol, methan

Request for a quote

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

STAIGER

Germany

Proportional regulation and control of high flow rates • Frictionless movement; • High flow rates; • Small footprint and size; • Low power consumption; • Pressure-balanced; • High dynamics; This valve combines the advantages of the Spider-μProp technology with the benefits of a pressurebalanced valve. Due to its large orifice, high flow rates are possible. Furthermore, the valve is distinguished by a high reproducibility of the lift-off point. The electrical power consumption lies thereby in the lowest range of the Plate Armature Technology. The compact design of the valve provides a variety of assembly options for different areas of application.

Request for a quote

FISCHER FORTUNA GMBH

Germany

High-performance grinding spindles with a watercooled asynchronous motor External taper on working side Pre-tensioning of the precision bearing groups using a spring system that does not have to be readjusted Long-lasting grease lubrication Non-wearing labyrinth seal system with air seal Spindles are completely dynamically balanced Taper true running <= 0.002 mm Drive via frequency converter Diameter to length ratio of up to 1:20 possible Further available spindle dimensions are listened in the spindle datasheet below (PDF download 312KB). Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quote

FISCHER FORTUNA GMBH

Germany

High-performance grinding spindles with a watercooled asynchronous motor External taper on working side Pre-tensioning of the precision bearing groups using a spring system that does not have to be readjusted Long-lasting grease lubrication Non-wearing labyrinth seal system with air seal Spindles are completely dynamically balanced Taper true running <= 0.002 mm Drive via frequency converter Diameter to length ratio of up to 1:20 possible Further available spindle dimensions are listened in the spindle datasheet below (PDF download 312KB). Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quote

FISCHER FORTUNA GMBH

Germany

High-performance grinding spindles with a watercooled asynchronous motor External taper on working side Pre-tensioning of the precision bearing groups using a spring system that does not have to be readjusted Long-lasting grease lubrication Non-wearing labyrinth seal system with air seal Spindles are completely dynamically balanced Taper true running <= 0.002 mm Drive via frequency converter Diameter to length ratio of up to 1:20 possible Further available spindle dimensions are listened in the spindle datasheet below (PDF download 312KB). Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quote

FISCHER FORTUNA GMBH

Germany

High-performance grinding spindles with a watercooled asynchronous motor External taper on working side Pre-tensioning of the precision bearing groups using a spring system that does not have to be readjusted Long-lasting grease lubrication Non-wearing labyrinth seal system with air seal Spindles are completely dynamically balanced Taper true running <= 0.002 mm Drive via frequency converter Diameter to length ratio of up to 1:20 possible Further available spindle dimensions are listened in the spindle datasheet below (PDF download 312KB). Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quote

FISCHER FORTUNA GMBH

Germany

Spindles with air-cooled, three-phase, built-on motor Pre-tensioning of the precision bearing groups using a spring system that does not have to be readjusted Long-lasting grease lubrication Non-wearing labyrinth seal system Spindles are completely balanced dynamically Taper true running <= 0.002 mm Drive via frequency converter or direct connection to main power supply Diameter to length ratio of up to 1:20 possible Further available spindle dimensions are listened in the spindle datasheet below ( PDF download 190KB). Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Powerful and service reduced Dome Pressure Regulator applicable for mounting in pipeworks. Benefits: high pressure stability even when subject to fluctuations in withdrawal enables process reliability Pilot Control Tube (PCT) for particularly high constant outlet pressure applicable for almost all gases accurate dynamic regulation high flow rate Balanced Seat Design (BSD) for better control precision complete mounted, inclusive pressure gauge, pilot pressure regulator and fittings working pressure changable at any given moment (readjustable) – e.g. due to temperature fluctuations provides constant working pressure by dynamic control no disperse of pilot gas to the environment – closed system pressure gauges optionally in stainless steel and/or filled with glycerine indoor and outdoor installation connection for wall mounting panel easy installation and removal

Request for a quote

FISCHER FORTUNA GMBH

Germany

Spindles with air-cooled, three-phase, built-on motor Pre-tensioning of the precision bearing groups using a spring system that does not have to be readjusted Long-lasting grease lubrication Non-wearing labyrinth seal system Spindles are completely balanced dynamically Taper true running <= 0.002 mm Drive via frequency converter or direct connection to main power supply Diameter to length ratio of up to 1:20 possible Further available spindle dimensions are listened in the spindle datasheet below ( PDF download 190KB). Spindles are not sold on the Webshop, but spindle inquiries are accepted.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ODDESSE PUMPEN- UND MOTORENFABRIK GMBH

Germany

Submersible motors from oddesse are used as pump drive for applications with special requirements, such as in mining, utilisation of geothermal energy as well as in offshore and marine technology. EXECUTIONS - Three-phase asynchronous motors for 50 or 60 Hz and voltages up to 1,000 V - Water-filled motors with rewindable stators, dynamically balanced and with high resistance to thermal stress High-quality thrust bearings that operate in both rotation directions and possess a high load-bearing capacity - Water-lubricated radial bearings for a horizontal and vertical motor application - Windings for temperatures up to 80° C of the pumped medium available - Speed regulation between 30 and 60 Hz via frequency converter possible - High-quality materials for application in service, industrial and seawater PERFORMANCE RANGE (AT 50 HZ) Up to 45 kW/60 HP with 6" motors Up to 132 kW/175 HP with 8" motors Up to 220 kW/300 HP with 10" motors Up to 400 kW/550 HP with 12" motors

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

The main characteristics of the forced ventilation unit are short assembling measures. The ventilations are static and dynamically balanced, thus, of a high balance quality. The diameter, the length as well as the side punchings can be made to customer´s requirements.

Request for a quote

HAVER NIAGARA GMBH

Germany

The F-CLASS series is a new development based on the successful operational principle of the NIAGARA® Scalper. It is foremost used in the area of classifying, but because of its robust construction, it can be used as a scalper as well. The F-CLASS is a dynamically balanced vibrating screening machine that employs the eccentric design. It has buffered external bearings for optimum protection against high impact loads to the drive shaft and carrier frame. The F-CLASS eccentric screening machine fundamentally operates with a load-independent, constant circular vibration motion. The stable circular vibration effectively prevents material cake-up in the screening box and clogging of the screen. Thus the requirements for increased product quality, defined wrong size particle amount, and maximum good particle yield are fulfilled. The unique HAVER carrier rail system permits the installation and combination of a variety of manufacturer independent screen types. The application area of...

Request for a quote

HAVER NIAGARA GMBH

Germany

The NIAGARA® scalper is the best choice for crushing plants or the classification of coarse and difficult-to-screen materials at high throughput rates and fluctuating material feed rates. The unique NIAGARA® drive system generates a constant circular vibration motion at a fixed amplitude. The amplitude remains unchanged over time, no matter what the material load is. The application area of the NIAGARA® Scalper covers a variety of industries and materials with a length of up to 2000 mm and a cut size of 2 - 450 mm. Advantages reduced loads and energy demands for the subsequent crushing plant increased crusher capacity maximising the quality of the crushed product quick and easy re-balancing is always possible built with long-life bearings maintenance-friendly, modular machine design dynamically balanced construction modernisation of existing plants, performance improvement You’ll find detailed information in our product brochures and specification sheets.

Request for a quoteResults for

Dynamic balancing - Import exportNumber of results

22 ProductsCountries

Company type