- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drive roller

Results for

Drive roller - Import export

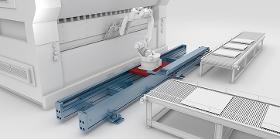

ROLLON GMBH

Germany

Shuttle system for moving robots and heavy loads for long distances with high dynamics. The motion system is available with recirculating ball guides or rollers while the driving system has been designed with rack and pinion. The shuttle is equipped with adjustable ties to achieve alignment even on irregular surfaces. Cable carrier and dampers at the stroke end are included. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

GSW SCHWABE AG

Germany

To serve coil stock thicknesses of up to 15 mm Large diameter entry pinch rollers for smooth and lowwear strip transport Synchronized drive of all bottom work rollers and both entry pinch rollers Rollers are kept perfectly parallel with their penetration shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Enormous potential for performance and straightening quality through absolutely warpresistant head construction; supported by optional backup rollers and allroll drive system Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening as "cleaning stroke" Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Great feeding accuracy of +/ 0,1 mm Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Synchronized drive of all bottom work rollers and both feed rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic full piloting Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable for highstrength steel applications Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

GSW SCHWABE AG

Germany

Most simple threading Short setup as roller adjustment can be maintained with coilchanges Most comfortable maintenance and cleaning Synchronized drive of all bottom work rollers and both pinch rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive Movable base Manual or hydraulic loop bridge... etc.

Request for a quote

BLICKLE RÄDER+ROLLEN GMBH U. CO. KG

Germany

Drive wheels are used to drive appliances and equipment. They use the force generated by a motor within the appliance to get it moving. One area where they are currently used is in the drum systems of wind turbines. Blickle has developed a heavy duty drive roller for the wind power industry. Click here to find out more in our success story. Drive wheels use a hub keyway and key to connect the wheel to the axle. This connection is also used for hub fitting wheels. Hub fitting wheels are also used to drive machinery and vehicles.

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

PU V-belts run individually or alongside one another and convey products on slightly ascending or descending conveying systems without allowing the products being transported, e.g. boxes, tiles, glass slabs, cardboard articles etc., to slip. In addition, PU V-belts are used for driving live roller conveyors. Standard stock program: 75° Sh.A red 80° Sh.A transparent, FDA 80° Sh.A sky-blue, FDA 85° Sh.A green 90° Sh.A white Profiles 6x4 / 8x5 / 10x6 / 13x8 / 17x11 / 22x14 Smooth or notched

Request for a quote

FORBO SIEGLING GMBH

Germany

Siegling Round belts are used for conveying in the textile, wood-working, ceramic, packaging and chemical industries.Siegling Transilon round belts serve as efficient drive elements in both precision tool and machinery manufacturing. Siegling Round belts have also proven their reliability as drive elements for live roller conveyor repeatedly. Their great flexibility and elasticity make any turn possible.

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G1 series (with closed impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern on roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. * Suitable for flow rates up to 30 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

LUTZ PUMPEN GMBH

Germany

The B80 KGK G2 series (with open impeller) is a powerful and robust centrifugal submersible pump with plain bearings, drive lantern with roller bearings and IEC standard motor. The pumped liquid is conveyed from the tank via the radial pump outlet and the vertical riser pipe. Power is transmitted from the motor to the pump by means of a torsionally flexible, positive-locking coupling and is designed for continuous operation. *Suitable for flow rates up to 80 m³/h * equipped with a suction strainer as standard * suction pipe extension up to 2000 mm is possible * available in immersion depths from 500 - 4000 mm Features & advantages * No screws in contact with the medium * Vibration and oscillation-free operation * Long service life and operational reliability * Lifetime grease-lubricated roller bearings * Independent bearings for motor and pump * External flushing to protect the plain bearings with media containing solids

Request for a quote

GUMMIWARENFABRIK EMIL SIMON GMBH & CO. KG

Germany

Robust version for workshops, test-beds etc. Suitable for hose rollers, drive-over proof, long-term loading up to 160°C, short-term to 190°C. Anti-kink finish due to plastic spiral with very good bending characteristics. Construction: Black EPDM tube Fabric inlays Embedded PA-Helix Black cover Interior smooth, exterior rectangular or round and ribbed coupling both ends In fixed lengths with cuffed ends and/or widened hose endings. Other versions and dimensions on request.

Request for a quote

MAHLO GMBH & CO. KG

Germany

When the going gets rough ... The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide materials. The arc of contact of the straightening rollers thereby depends on the desired straightening effect. With products without skews and bows, the straightening rollers are not enveloped unnecessarily. When the straightening rollers engage with the product, the uniform contact of the straightening rollers with the product is ensured over the entire width. This becomes possible through our innovative and unique roller positioning drive.

Request for a quote

BIEGLO GMBH

Germany

PAI material considers the most efficient fusible thermoplastic in terms of temperature resistance, chemical resistance and mechanical stress. Its mechanical strength at 205 °C surpasses many engineering plastics at room temperature. BIEGLO offers PAI finished parts of the following types: Torlon® 4203; 4301; 4275; 4435; 4645; 5030 (30% GF); 7130 (30% CF). Each type is best suited for a particular application. Polyamide-imide can be used for a lot of appliations like gears, rollers, plasma chamber hardware and wafer contact fixtures. In addition, PAI material is ideal for high-temperature thermal insulators, burn-in test sockets, valve seats, fasteners, mechanical connections, rollers, labyrinth seals, drive wheels, valve plates, vanes and support gaskets.

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Transport and drive rollers must provide precise transport of the print media in the digital printing process. This is especially true for wide format inkjet printers. Tracking lines, artifacts on the printout, or paper feeding failures are not accepted by the end-user. Our transport rollers are subject to the highest quality standards in respect to: Perfect, defect-free surfaces Precisely defined surface roughness High friction stability over life Tight tolerances in all dimensions

Request for a quote

HORTON EUROPE GMBH & CO. KG

Germany

Suspension Products Horton Roller Bushings Suspension Product last for hundreds of thousands of miles so they rarely need to be replaced — saving you costly downtime and repair costs. Traditional spring pins and bushings aren't designed to withstand the daily abuses of the road. Roller Bushings from Horton provide a long-term lubrication necessary for a properly maintained suspension system. Now you can eliminate the worry of seized pins and front wheel hop. Benefits - Smoother ride - Improved handling - Less chassis stress - Trouble-free solution Features - Special ribbed casing for easier installation - Patented needle bearings provide maximum lubrication - Dual lip seals keep dirt out Links - Order or View Literature - Roller Bushings Suspension Product Catalog

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Precision Transmission Chains from iwis:Roller chains / Transmission chains

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

Facts: — easily running — low empty weight Different versions — Pipe diameter: 50 mm, 30 mm, 80 mm, 60 mm, 40 mm — Tube material: Galvanized steel — axis diameter: 8 mm, 12 mm — Axle material: steel — Axle type: Female thread, spring axle, rigid/smooth — Load capacity according to design (max. 240 kg / roll) Depending on the model: — suitable for lateral tasks — dished roller floor — antistatic — Splash water and dust protection — suitable for high speeds — suitable for heavy goods to be conveyed

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

Plastic load-bearing rollers, transport rollers and roller lines are light and robust. This will enable you to provide quick and efficient intralogistics. Facts: — easy running — low empty weight Different versions — Pipe diameter: 50 mm, 40 mm, 20 mm, 60 mm — Tube material: grey plastic, blue plastic, galvanised steel — Axis diameter: 8 mm, 6 mm, 12 mm — Axle material: steel, plastic — Axle design: Spring axle, smooth/rigid — Load capacity according to design (10 kg / roll, 14 kg / roll, 20 kg / roll, 200 kg / roll)

Request for a quote

ROS ROLLENTECHNIK GMBH

Germany

We offer you exactly the right conveyor and drive chains to match your transport rollers. Each chain is tailor-made in material and design. This means that you benefit from low maintenance costs and ensure the long-term stability and safety of your goods transport system. The chains are available as yard goods or as ready-to-install, deflected and closed chains. At TRAPOROL you’ll get exactly the right chain and driven wheels to fit your transport rollers on request. We’ll ensure that the material and design of every chain is exactly tailored to your purpose. So you’ll make a big reduction in maintenance costs and gain high performance for your transport system long term. Whether by the metre or ready-to-assemble and enclosed: all the chain wheels supplied are produced in accordance with DIN ISO 606 (ex-DIN ISO 8187) and meet even the highest demands.

Request for a quote

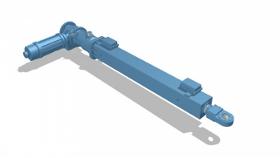

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

In many areas of mechanical engineering, electromechanical drives are replacing hydraulic units in order to avoid the risk of oil leaking into water or the danger to people from burning liquids. Our electric lifting cylinders have been specially developed for use in hydraulic steel construction. They are suitable as drives for contactors and bridge actuation, as well as for lock gates and barrages. With our modular system, various designs such as trapezoidal, ball or planetary roller screw drive can be realized. Limit switches for permanent travel or load measurement can be integrated. The drive systems are equipped with environmentally friendly, biodegradable fat filled to meet the strict environmental requirements. They are characterized by a special design adapted to the intended use, a high level of serviceability and versatility. Our electric lifting cylinders form a reliable and sustainable alternative to hydraulic lifting cylinders in various fields of application.

Request for a quoteResults for

Drive roller - Import exportNumber of results

24 ProductsCountries

Company type

Category

- Metal straightening machines (6)

- Goods handling systems, continuous (2)

- Pumps (2)

- Conveyor belts (1)

- Cylinders, hydraulic (1)

- Fittings, pipe, tube and hose - plastic (1)

- Internal transport systems (1)

- Labelling machines (1)

- Mechanical surface treatment - machinery (1)

- Mechanical transmission systems and components (1)

- Textiles - Machines & Equipment (1)

- Transmission belts (1)

- Transportation chains (1)

- Wheels, castors and rollers (1)