- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- joints

Results for

Joints - Import export

EPOWIT BAUTECHNIK GMBH

Germany

very fast curing, high flexibel, abrasion and UV stable surface protection for concrete

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

The performance of an assembly tool is highly dependent on the conditions of the actual production joint on which it is used, which is where joint kits come in. Joint kits are an essential accessory for accurate off-line testing of powered assembly tools. Tooling engineers are well aware of the "mean shift" term used to describe the different torque delivered by the same tool when applied to a soft or a hard joint as defined by ISO 5393. It is therefore essential in testing and setting up tools off the production line to allow for the joint conditions which the tool will experience on the job. Crane's joint kits satisfy this requirement by using a bolt and suitably configured disc washers allowing free running of the bolt and a subsequent torque gradient to closely match the production joint condition. [...]

Request for a quote

IGUS® GMBH

Germany

igubal® clevis joint, mm With and without pin and circlip igubal® clevis joint, mm igubal® clevis joints with spring loaded pins, mm igubal® clevis joints with spring loaded pins, mm igubal® clevis joint combination, mm Complete knee joints consisting of clevis joint and rod end bearing igubal® clevis joint combination, mm igubal® spring loaded pin, mm igubal® spring loaded pin, mm igubal® pin, mm GBM/GSR Pin and circlip igubal® pin, mm GBM/GSR igubal® clevis joint, detectable, mm igubal® clevis joint, detectable, mm igubal® clevis joints with spring loaded pins, detectable, mm igubal® clevis joints with spring loaded pins, detectable, mm igubal® spring loaded pin, detectable, mm igubal® spring loaded pin, detectable, mm Most important features: Very low weight High tensile forces Combinable with rod end bearings of the dimensional series E vibration dampening Noise dampening Available for left-hand and right-hand threads igubal® clevis joints are solid polymer made of igumid G according to DIN 71752, which can be combined with the rod end bearings of the dimensional series E as counterpiece. They consist of clevis joint, pin and circlip, or alternatively with spring loaded pin. igubal® spherical bearings application examples When to use it? When high stiffening is required When freedom from corrosion is desired When lubrication should not be used When you want to save weight When maintenance-free dry operation is desired When the easiest installation should be implemented When combinations with pneumatic cylinders and gas struts should be implemented When not to use? When temperatures above +200°C prevail When dimensions over 20 mm are needed igubal® clevis joint, mm With and without pin and circlip igubal® clevis joint, mm igubal® clevis joints with spring loaded pins, mm igubal® clevis joints with spring loaded pins, mm igubal® clevis joint combination, mm Complete knee joints consisting of clevis joint and rod end bearing igubal® clevis joint combination, mm igubal® spring loaded pin, mm igubal® spring loaded pin, mm igubal® pin, mm GBM/GSR Pin and circlip igubal® pin, mm GBM/GSR igubal® clevis joint, detectable, mm igubal® clevis joint, detectable, mm igubal® clevis joints with spring loaded pins, detectable, mm igubal® clevis joints with spring loaded pins, detectable, mm igubal® spring loaded pin, detectable, mm igubal® spring loaded pin, detectable, mm

Request for a quote

IGUS® GMBH

Germany

robolink®-2-axial joint: Weight: 400 g max. load: pivoting 12 Nm, rotating 5 Nm Pivot angle: 180° (+180°/0°) Rotation angle: 340° (± 170°) Material: Fine polyamide PA 2200, VA screws, Dyneema ropes, aluminum HC bearing (alternativ iglidur® J) A = rotating ±270° | B = pivoting ±180° - 0° C = rope run

Request for a quote

IGUS® GMBH

Germany

robolink®-based joint: Bearing ring rotation on the basis of PRT-01-50 iglidur® J gliding elements rotating on aluminium HC Weight: 1.250 g max. load: privot 20 Nm, rotate 10 Nm Pivoting angle: 180° (± 90°) Rotation angle: 180° (± 90°) Material: Fine polyamide PA 2200, VA screws, Dyneema ropes, aluminum HC bearing (alternativ iglidur® J) A = privoting ±90° B = rotating ±90°

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IGUS® GMBH

Germany

Oscillatory robolink® joint - optional with angle sensors material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) Balls: Oscillatory robolink® joint - optional with angle sensors material: robolink® joint: Fine polyamide PA 2200 Screws: stainless steel VA Ropes:Dyneema Bearing: Alu HC(alternative iglidur® J) Balls:

Request for a quote

IGUS® GMBH

Germany

igubal® - WGRM Angle joint for rotating and pivoting motions igubal® - WGRM igubal® low-cost angle joint Low-priced connection, many combination options igubal® low-cost angle joint igubal® axial joint AGRM For all mechanical combinations igubal® axial joint AGRM igubal® AGRM LC, AGLM LC Many combination potentials igubal® AGRM LC, AGLM LC igubal® removable angle joints Easy assembly and disassembly of the ball pins by defined forces igubal® removable angle joints adjustable Fixed position spherical bearings, clearance- free movement of the ball pin adjustable Replaceable Reduce costs and time with removable ball pins Replaceable igubal® - WGRM Angle joint for rotating and pivoting motions igubal® - WGRM igubal® low-cost angle joint Low-priced connection, many combination options igubal® low-cost angle joint igubal® axial joint AGRM For all mechanical combinations igubal® axial joint AGRM igubal® AGRM LC, AGLM LC Many combination potentials igubal® AGRM LC, AGLM LC igubal® removable angle joints Easy assembly and disassembly of the ball pins by defined forces igubal® removable angle joints adjustable Fixed position spherical bearings, clearance- free movement of the ball pin adjustable Replaceable Reduce costs and time with removable ball pins Replaceable

Request for a quote

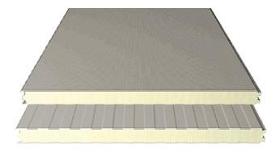

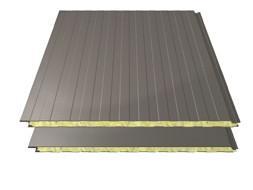

PANEL SELL GMBH

Germany

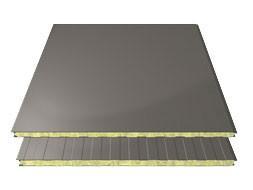

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

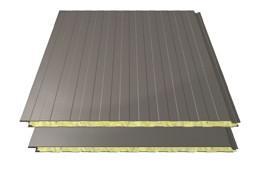

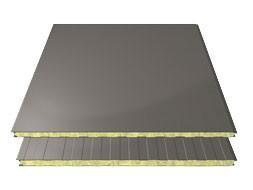

PANEL SELL GMBH

Germany

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

PANEL SELL GMBH

Germany

We can deliver at last-minute rockwool panels (A-grade production and B-grade surplus stock) for sound insulation and fire protection. Rockwool or mineral wool panels are sandwich panels whose sheets are connected firmly with rockwool insulation. These panels are therefore highly resilient composite panels that have both load-bearing and insulating functions. The panels insulation are made of around 95 - 99 % molten rock, and pulled into threads to obtain a fibrous structure. The fibres are evenly distibruted to ensure that the shear strength is kept constant. Rockwool panels are used in areas where fire protection requirements are needed. The rockwool panels can be installed either as an internal / external firewall, suspended ceiling, and as a roof structure. These panels can be laid vertically and horizontally due to its end joints. These panels can also be used for basic insulation of existing buildings. Building material classification according to EN 13501-1 A1 or A2 for a non-combustible material B, C, D, E for a combustible material, where B is lowest combustibility. A1 is the highest class and is not combined with any additional class. The other classes are always combined with the following additional classes which indicate the product's ability to produce smoke and flaming droplets and particles. s1 – the structural element may produce a very limited amount of combustion gases s2 – the structural element may produce a limited amount of combustion gases s3 – no requirement for limited production of smoke d0 – flaming droplets and particles may not be produced by the structural element d1 – a limited amount of flaming droplets and particles may be produced by the structural element Panels with rockwool insulation can also ensure peace in operation. With its core material properies, the panels can offer first-class sound absorption values, and good themal insulation The acoustic perforations on the flat inner surface of the panels means that they should only be used for inside walls, as the outside sheet is not air-tight. On request we can offer you a range of fire protection or acoustic panels made to your requirements in length, thickness and most RAL-colour tones. We are also able to offer special price products and cancelled orders.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

EPOWIT BAUTECHNIK GMBH

Germany

surface protection for concrete, crack filling, hydrophobic impregnation

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

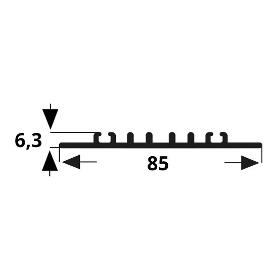

Shape: grooved butt connector, perforated Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, not completely artificially aged Surface: mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Width (mm): 85 Length (mm): 6,000

Request for a quoteResults for

Joints - Import exportNumber of results

16 ProductsCountries

Company type