- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- guides

Results for

Guides - Import export

CIC - KLAUS CZERWONKA

Germany

Guide units for attaching cylinders according to ISO 6432 and VDMA 15552. For moving heavy loads with high speed and positioning accuracy.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The compact, guided cylinder CC is a linear drive with a lot of power and minimal dimensions. Generously dimensioned guide rods on plain bearings or ball bearings open up a wide range of application options in variable positioning with and without sensor queries.

Request for a quote

CIC - KLAUS CZERWONKA

Germany

The compact, guided cylinder CC is a linear drive with a lot of power and minimal dimensions. Generously dimensioned guide rods on plain bearings or ball bearings open up a wide range of application options in variable positioning with and without sensor queries.

Request for a quote

IGUS® GMBH

Germany

drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration

Request for a quote

IGUS® GMBH

Germany

Maintenance-free, compact, quiet and cost-saving complete system - the alternative to the busbar system. For the safe guidance of energy, data, air and liquids in ONE system. - Easy to clean - No particle pollution due to abrasion - Quiet, lubrication-free, and easy to install - Operating speeds of up to 6 m/s in high-acceleration applications - Data rates up to 10 Gbit/s. Safely guides FOC and bus cables - Low space requirement

Request for a quote

IGUS® GMBH

Germany

DryLin® telescopic rails Total extensions Partial extensions Over-extensions DryLin® telescopic rails DryLin® telescopic rails with locking function Detent in start, medium and end position Freely selectable locking position DryLin® telescope - wth locking mechanism Completely lubricant-free linear extensions in continuous stroke lengths of 100mm to 600mm - maximum pulled-out length: 1200mm. The telescopic systems consist of anodized aluminum guide rails and a gliding block made of the proven iglidur material. By the incompounded solid lubricants, iglidur tribopolymers enable dry operation in every application. The advantage - besides being maintenance-free - is the carefree use in clean hygienic environments. No oil or fat can be transmitted to other products, clothing or people. Applications even in cleanroom air showers were already implemented. But the dry operation also has advantages in the dirt accumulation area. Dirt particles do not stick to the guide and do not become a sticky mass. As an option, all telescopic guides can be delivered with a detent in start-medium-end position. Requirements for individually positioned locking positions can be met. Detailed view: DryLin® telescopic rail in a guard door adjustment. DryLin® telescopic rails Total extensions Partial extensions Over-extensions DryLin® telescopic rails DryLin® telescopic rails with locking function Detent in start, medium and end position Freely selectable locking position DryLin® telescope - wth locking mechanism

Request for a quote

IGUS® GMBH

Germany

drylin® Q Square linear guides Square section tube made of hard-anodized aluminum Torque resistant without 2nd guidance Tolerates moments up to 10 Nm drylin® Q square section tube drylin® Q - bearing housing, adjustable Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually drylin® Q - bearing housing drylin® Q - bearing housing, adjustable with hand clamp Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually With manual clamp drylin® Q - bearing housing with manual clamp drylin® Q - housing bearing Q20 enclosed, anodized aluminium housing short design or tandem housing Torque resistant without 2nd guidance drylin® housing bearing Q20 drylin® W - flange bearing Flange pillow block made of anodized aluminum Round flange (01 version), square flange (02 version Standard type or tandem housing Torque resistant without 2nd guidance drylin® W - flange bearing drylin® Q - housing bearing Q10 Solid polymer bearing made of iglidur® J Very light Tolerates moments up to 3 Nm Space saving drylin® Q - housing bearing Q10 drylin® Q - accessory Based on a torque resistant square guide with 7.5 mm edge lengths Hollow chamber for supply lines (media, compressed air,cable) drylin® Q - accessory drylin® Q - gripper axis Toothed, hard-coated and corrosion protected square-hollow profile Move loads up to 500 g at speeds of up to 0.7 m/s Bearing made of iglidur® J Drive: NEMA11 stepper motor with gear wheel drylin® Q - gripper axis Move linear torque resistant, completely lubrication-free. The drylin® Q linear construction kit offers the user maximum flexibility in the design Individual housing options such as solid plastic bearings and adjustable complete housings with and without manual clamp are available. Due to the hollow chamber design, the rugged hard-anodised aluminium profile is very light and is suitable for the simultaneous conducting of supply cables. The mounting options are highly variable, among others, using slot nuts; installation size 20 can also combined with all 20/20 aluminium construction profiles. 1. Profile made of hard-anodized aluminum 2. Main body of the carriage made of aluminum 3. Customized clearance adjustment 4. Cover made of solid plastic 5. Gliding elements in high-performance polymer iglidur® J serve as a guide bearing and guarantee optimum running properties drylin® Q Square linear guides Square section tube made of hard-anodized aluminum Torque resistant without 2nd guidance Tolerates moments up to 10 Nm drylin® Q square section tube drylin® Q - bearing housing, adjustable Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually drylin® Q - bearing housing drylin® Q - bearing housing, adjustable with hand clamp Carriage version for all unsupported solutions Force absorption from all directions Anti-rotation Clearance is continuously adjustable manually With manual clamp drylin® Q - bearing housing with manual clamp drylin® Q - housing bearing Q20 enclosed, anodized aluminium housing short design or tandem housing Torque resistant without 2nd guidance drylin® housing bearing Q20 drylin® W - flange bearing Flange pillow block made of anodized aluminum Round flange (01 version), square flange (02 version Standard type or tandem housing Torque resistant without 2nd guidance drylin® W - flange bearing drylin® Q - housing bearing Q10 Solid polymer bearing made of iglidur® J Very light Tolerates moments up to 3 Nm Space saving drylin® Q - housing bearing Q10 drylin® Q - accessory Based on a torque resistant square guide with 7.5 mm edge lengths Hollow chamber for supply lines (media, compressed air,cable) drylin® Q - accessory drylin® Q - gripper axis Toothed, hard-coated and corrosion protected square-hollow profile Move loads up to 500 g at speeds of up to 0.7 m/s Bearing made of iglidur® J Drive: NEMA11 stepper motor with gear wheel drylin® Q - gripper axis

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

IGUS® GMBH

Germany

DryLin® R - Installation videos System selection & service life calculation DryLin® R - Introduction and technical information Special info on DryLin® R linear plain bearing L1 series drylin® igus® test method Liners and pressfit bearings Open and enclosed DryLin® R liners Linear Bearings Open, enclosed, split and self-aligning DryLin® R linear plain bearing Housing bearing Enclosed linear bearing, adjustable, split, in tandem design and as floating bearing DryLin® R housing bearing Flange housing Linear bearing with round or angular flange DryLin® R flange housing Carriage and linear housing Open or enclosed in several long designs DryLin® R carriage and linear housing Shaft end supports and shaft blocks Fixed and moving shaft end supports, shaft blocks in several designs DryLin® R shaft end supports and shaft blocks Shafts and supported shafts Shafts made of aluminum, steel and carbon fiber DryLin® shafts and supported shafts Linear round guide DryLin® R linear plain bearings are based on extremely wear-resistant polymers specially developed for the linear technology. The dimensions are compatible with standard ball bearings. The special geometry guarantees ruggedness even in extreme environments. DryLin® R - Installation videos Advantages: 100 % lubricant-free Dimensionally interchangeable with (recirculating) ball bearings Large variety of choice in housing shapes Shafts, shaft blocks and accessories available from stock 8 different shaft materials Replaceable liners VA stainless steel housing available When not to use it? When little installation space is available drylin® N drylin® W When twist-protection is required for single-axis systems DryLin® T DryLin® N Liners and pressfit bearings Open and enclosed DryLin® R liners Linear Bearings Open, enclosed, split and self-aligning DryLin® R linear plain bearing Housing bearing Enclosed linear bearing, adjustable, split, in tandem design and as floating bearing DryLin® R housing bearing Flange housing Linear bearing with round or angular flange DryLin® R flange housing Carriage and linear housing Open or enclosed in several long designs DryLin® R carriage and linear housing Shaft end supports and shaft blocks Fixed and moving shaft end supports, shaft blocks in several designs DryLin® R shaft end supports and shaft blocks Shafts and supported shafts Shafts made of aluminum, steel and carbon fiber DryLin® shafts and supported shafts

Request for a quote

IGUS® GMBH

Germany

E4Q energy chains have been developed to provide the best possible solution for unsupported and long travels. Based on the robust E4.1 energy chain standard, which has proven itself over 12 years, the new series brings a long service life and high modularity. - Tool-free opening and closing - Reduced protrusions in the interior, for easier filling when the e-chain® is open - 15 % more pull-out force of the opening webs compared to the E4.1 system - 10 % less weight due to material recesses compared to system E4.1 - Optional 17 dB(A) quieter due to noise-reducing parts made of material optimized for noise level - 40 % less installation time compared to system E4.1 - Up to 35 % savings possible when used in the limit range - 36 months warranty - Predictive maintenance - optional with the isense add-on module Typical applications: Machine tools, crane systems, automation systems

Request for a quote

IGUS® GMBH

Germany

Safely guide many different cables in a confined space with e-spool. e-spool uniquely combines two different energy supply systems: one standard energy chain is guided by a roller, providing the correct length and tension of the energy supply system through an integrated spring. In the home position, the energy chain is completely rolled up to save space. The twisterband connects the roller with the shaft end block, serving as an interface to the supply side cables. - According to DIN EN 17206 and DGUV principle 315-390 - No tensile strain on the cables - Energy supply is possible in all directions (horizontal, vertical, diagonal) - Space-saving, no "chain station", as the energy chain is rolled up in the starting position, ensuring the paths remain clear - Cables can be retrospectively added or changed - Maximum extension and retraction speed 1m/s

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Guide rail brackets galvanized Item-no.: FS1 0000 A0 000 000

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Spring lock washers acc. to DIN 127

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

US-type guide rail anchors galvanized surface Please find results of calculation of stability in our download area:

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Sliding clips type RC galvanized surface

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Hexagon head screws with thread to head acc. to DIN 933-8.8 (ISO 4017) galvanized surface

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SÜTHER & SCHÖN GMBH

Germany

Clamping clips according to DIN 3568 hot-dip galvanized surface Please find results of calculation of stability in our download area:

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Clamping clips for the structural steel engineering for I and IPB beams galvanized surface Please find results of calculation of stability in our download area:

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Clamping clips similar to DIN 15313 with hexagon socket suitable for hexagon head screws acc. to DIN 933 galvanized surface Please find results of calculation of stability in our download area:

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

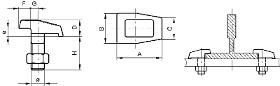

Clamping clips for guide rails acc. to DIN 15313 galvanized surface * not acc. to DIN 15313 Type W (only on inquiry): Please find results of calculation of stability in our download area:

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Attachment screws for fastening guide rails forged /galvanized surface quality of material 6.8 Please find results of calculation of stability in our download area:

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Hexagon nuts acc. to DIN 934-8 (ISO 4032) galvanized surface

Request for a quote

HEINZE & STRENG GMBH

Germany

For our carbon fibre bows, we offer wire guide elements for custom equipping made of: ceramic- carbide- tempered steel and special roller designs

Request for a quote

HEINZE & STRENG GMBH

Germany

Best quality, grinded and polished with an excellent surface

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has been a successful innovator and manufacturer of ball guides for linear motion technology for decades. SCHOCK ball guides are known for their precision, high load capacities, and long lifespan. Key features of SCHOCK ball guides include: Excellent running properties High operational reliability Long lifespan without maintenance Custom connection options Based on individual customer requirements, we develop and manufacture ball guides as runner guides, partial extension, full extension, or over-extension. In collaborative project planning with our customers, we define the product requirements for the ball guides. Our customers benefit from a wide selection of rail profiles, mounting systems, comfort features, and high-quality surface finishes, such as SCHOCK powder coating. We supply powder-coated ball guides in any desired RAL color, offering you unique design possibilities.

Request for a quote

WAELAG WÄLZLAGER VERTRIEBS- GMBH

Germany

AL/BL sliders with light-(Z) or medium (H) preload are standard stock items with prompt delivery AL:Normal length, low height-square type slider with tap holes on top BL:Long length, low height-square type slider with tap holes on top

Request for a quote

WAELAG WÄLZLAGER VERTRIEBS- GMBH

Germany

EM/JM sliders with light- (Z) or medium (H) preload are standard stock items with prompt delivery EM:Normal length, low height flange slider with tap/trough holes JM:Short length, low height flange slider with tap/trough holes

Request for a quote

WAELAG WÄLZLAGER VERTRIEBS- GMBH

Germany

EM/GM sliders with light- (Z) or medium (H) preload are standard stock items with prompt delivery EM:Normal length, low height flange slider with tap/trough holes GM:Long length, low height flange slider with tap/trough holes

Request for a quoteResults for

Guides - Import exportNumber of results

36 ProductsCountries

Company type