- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting tools

Results for

Cutting tools - Import export

CUPASO DEUTSCHLAND GMBH

Germany

Available in different sizes and for film webs from 310 mm to 610 mm. Optionally with roller knife cut for soft blisters or die-cutting tool for hard blisters. Additional equipment options for online printing, vacuum, MAP, automatic loading system and much more.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

During re-machining, a cutting tool is used to remove material from a workpiece in order to shape or surface it as required. We offer re-machining (turning, twisting) as wage work. The following machining operations we offer: Turn thin stem, pins and tips Screw punctures, approaches and undercuts Heads of screws / cold shaped parts machining process (turning) further machining operations are possible on request. Our curve-controlled automatic Audrema lathes offer you further possibilities of finishing cold-moulded parts. These automatic lathes are designed to achieve maximum precision and reproducibility at high throughputs. Short loading and unloading times permit economical production of medium-sized and large series.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

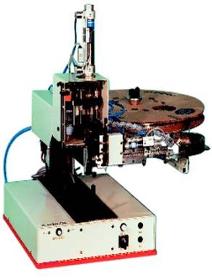

TYP A 040/B Solder lug inserting with tape feeder Description The solder lug inserting device Type A 040 B, was constructed for a mechanised insertion of solder lugs. Fixed cycles of less than one second are within easy reach. A Foot pedal controls the individual stroke sequence. The taped solder lugs are automatically fed into the machine. Therefore, no additional material and wage costs for threading the solder lugs on leads will arise. The device is able to process all kind of taped solder lugs with standard forms. After a slight alternation, solder lug strips, which deviate from standard, can also be processed. To do this, you simply have to replace the insertion head with stripe guide and the cutting tool, which is fast and easy to do. All driving elements and electrical switches belong to the main machine and therefore, they do not have to be moved. The bearing pedestal for the material bin can hold coils up to 500 mm ø. An adjustable conical ring centres the coil on the bearing pedestal. Working with this device is very easy and save. Components

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cutting tools - Import exportNumber of results

4 ProductsCountries

Company type