- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylindrical roller bearings

Results for

Cylindrical roller bearings - Import export

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

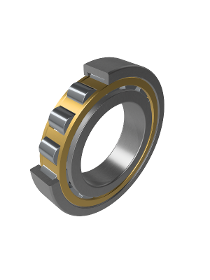

When it come to cylindrical roller bearings, at SLF we produce only the highest quality and precision. Our cylindrical roller bearing come in a verity of styles and sizes. They range from 30 to 1600mm We manufacture these bearing in standered and specialy materials, special lubrication, special heat treatment and higher levels of precision. are produced in single-row, double-rowed, multiple-rowed and fully complement versions, with a wide range of radial load-bearing capacity We offer multiple types of cage and roller materials

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Single row cylinder roller bearings with retainer are available as loose bearings, support bearings and fixed bearings. In the range of single row cylinder roller bearings are the model types N, NJ, NU and NUP, whereas the model series NN includes the double row cylinder roller bearings.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

We offer our KIS cylindrical roller bearings in various designs and sizes. In addition to the number of roller rows and the design of the cage, the flanges on the inner and outer rings are also considered. Due to their low friction and high rigidity, our cylindrical roller bearings are the perfect, durable solution for applications with high radial loads. They can also compensate for axial displacements (e.g. due to thermal expansion) and are available in sealed designs. Sealed cylindrical roller bearings are protected from dirt, water and dust. The seal prevents the ingress of contaminants and keeps the lubricant in the bearing. Together with you, we will be happy to develop a customised KIS solution for your requirements.

Request for a quote

WAELAG WÄLZLAGER VERTRIEBS- GMBH

Germany

High Rigidity Series

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

double row cylindrical roller bearings ball bearings spherical roller bearings cylindrical roller bearings specified by UIC double row cylindrical roller bearings standardized by UIC single and double row tapered roller bearings standardized by UIC axle box transmission traction motors B-asymmetrical rollers C-symmetrical rollers R-bearings without inner rings M-machined brass cage, roller centered MA-machined brass cage, outer ring centered TN-injection moulded cage of glass fibre according with ISO 281:2007 W33-annular groove and three lubrication holes P6-according with ISO tolerance class 6 No code-standard C3-greater than standard C4-greater than C3 K-tapered bore ratio 1:12 No code-cylindrical

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

require high precision, large rated moving load, and high maximum rotation speed. By adopting the new technology of material processing, KFB has successfully manufactured bearings of long service life that are highly fatigue resistant and impact resistant. The types of bearings made by KFB for the metallurgical roller mills are: split bearings; unit rollers; support roller bearings; single row, double row, three row, four row cylindrical roller bearings, fully-loaded cylindrical roller bearings, spherical roller bearings. The use of split bearings appreciably facilitates assembly and repair operations compared to the use of nonsplit (conventional) bearings. It does away with the need for the disassembly and subsequent reassembly of intermediate parts and mechanisms, which is required when replacing conventional bearings. It also reduces costs and production losses. If provided with efficient cooling, reliable lubrication and proper sealing, split-bearing components can be used...

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

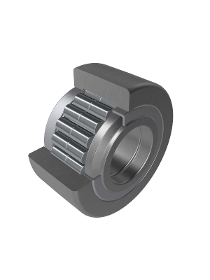

Similar in design to yoke type track rollers with axial guidance, our KIS cam rollers are based on needle roller or cylindrical roller bearings. Instead of an inner ring, they are equipped with a solid bolt. This serves as an inner ring replacement and is provided with a fastening thread. They are ideal for applications that require high rigidity, load carrying capacity and guiding accuracy. Our stud type track rollers are used, for example, in conveyor technology, machine tools and medical technology. Depending on the application requirements, the KIS range offers a wide variety of designs. We are happy to advise you on the right solution for your application!

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

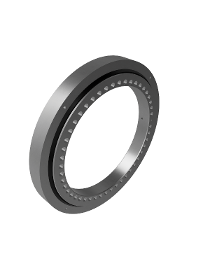

Designed to efficiently support axial and radial forces and tilting moment loads, crossed roller bearings are suitable for applications subject to high loads and speeds. Due to the special crosswise arrangement of the cylindrical rollers in crossed roller bearings, designs with two bearing positions can often be reduced to one. Due to their high rigidity and running accuracy, they offer enormous precision and are used, for example, in robotics, medical technology and lathes. Depending on the application requirements, we at KIS manufacture cross rollers in different configurations. We are happy to advise you on the optimum solution for your application.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our yoke type track rollers are available as single or double row needle roller or cylindrical roller bearings. Depending on the application requirements, the KIS range offers different ready-to-fit variants. Equipped with particularly thick-walled outer rings, our yoke type track rollers can support high radial loads and tolerate axial loads from minor misalignments, skewed running or short-term start-up shocks. Yoke type track rollers are mounted on axles and supported on a flat raceway (mating track). To meet specific requirements, we offer a wide range of different variants. Together with you, we develop the customised KIS solution carefully considering the use of cages, rib rings, seals and the profile of the outer ring running surface.

Request for a quote

FÖHRENBACH GMBH

Germany

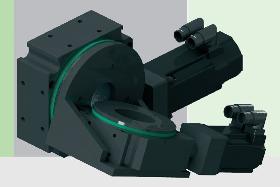

The new designed rotary swivel unit RT2A is the ideal solution for retrofitting your machine with a 4th and 5th axis. It is based on the proven and robust rotary tables of the RT2A series. The design is kept very compact to ensure the best possible use of space with high load capacity. The rotary tables are equipped with an integrated precision roller bearing, which ensures high torque capacity, radial and axial run-out accuracy. The rotary swivel unit RT2A is available in the size variants RT2A150/200 and RT2A100/150. Various stepper or servo motors can be used as drives. In addition, various types of end or reference point switches are available. The swivel range of the swivel axis can be individually defined, the rotary axis can be rotated without limit. Thus the RT2A rotary swivel unit combines all the advantages of a field-proven standard product with the flexibility of a special version.

Request for a quote

FÖHRENBACH GMBH

Germany

A lever clamping permits a simple, fast and exact adjusting of different working levels, without any efforts to adapt the devices. The swivel unit is available for the rotary tables RT2A075, RT2A100, RT2A150 und RT2A200. Field of applications: Assembly technologies, measuring and testing equipments, laser writing, welding, cutting, as well as special mechanical engineering. Features (RT2A100, RT2A200): Individually adjustable swiveling range from -5° to +95°. Fixed stop iin the 0° and 90°. Other positions possible by customer request. Clamp and locking effect through laterally installed, adjustable clamping lever. On one side appropriate scaling in 1° steps. Fixing of the swivel unit through four countersinking holes in the base plate.

Request for a quote

FÖHRENBACH GMBH

Germany

Rotary tables with direct drive series RT3 The rotary tables with direct drive are available in different types: RT3A100x100, RT3A100x155, RT3A080x130, RT3A150x100, RT3A150x130, RT3A250x170, RT3A200x060 und RT3G630x225 Rotary tables RT3G630 – high dynamics, high precision, high loading capacity This direct driven rotary table RT3G630 has particularly been developed for machine tool industry and assembly machines. It is characterised by its high precision, highdynamics and its high loading capacity. The rotary table is driven by a permanently excited 3-phase synchronous motor. The rotary plate and the housing are made of gray cast iron.

Request for a quote

FÖHRENBACH GMBH

Germany

While the conventional drives are dependent on an external controller unit, for the compact drives no additional controller is needed. The complete electrical parts, including the drive controller and encoder, are integrated on the motor board. Programming is done via standard PC using free software. The operation can be done without a PC, the created driving programs are stored in the compact drive and can be accessed via a separate input. Compact design Integrated motor controller and encoder RS485 or CANopen Interface Operating modes: positioning, speed, flag-position, clockdirection, analog, analog position, torque Position monitoring with automatic error correction up to 0,9° Step resolution max. 1/64 Integrated temperature monitoring Step frequency 0-50 kHz at clock-direction-mode and 0-25 kHz at the other modes

Request for a quote

FÖHRENBACH GMBH

Germany

The series of RT2A distinguishes by compact design with integrated precision roller bearing and worm drive. The rotary tables are sealed, IP 50 and can be driven in all fitted positions. For the mounting, standard drilling plans and special mounting flange and clamps can be used. Different limit switches are available: Standard: reference impulse, PNP-NC, 2 channel.

Request for a quote

FÖHRENBACH GMBH

Germany

This multisided applicable precision rotary table is available in installation size of 300 mm of rotary plate diameter. The rotation plate is stored by a tempered roller-bearing. This enabled high moment rigidity within the radial and axial range as well as free positioning at less friction moments. The drive takes place alternatively via stepper- or AC servomotors by a hardened and polished precision worm with a worm wheel of bronze. The rotary table is horizontal and vertically applicable by standard drilling plan and bolting face.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GURTEC GMBH

Germany

A roller with a solid shaft as standard, hollow shaft as option Bearing seats formed as an integral part of the shell, the opposing bearings are therefore accurately aligned The formed bearing holders improve bearing performance leading to lower failure rates Dimensions: Roller diameters 152 – 219 mm (6” to 8-5/8”) Shaft diameters up to 62 mm (2-1/2”) Bearings 6306, 6308, 6310, 6312

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

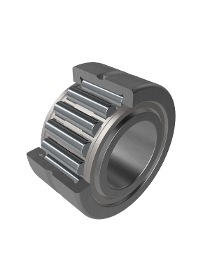

KIS needle roller bearings are ideal for applications that require space-saving rolling bearings with high load carrying capacity. We offer needle roller bearings in both radial and axial designs as well as in combined designs. In bearing technology, cylindrical rolling elements are referred to as needles if the rolling element diameter is ≦ 6 mm and the ratio of rolling element diameter to rolling element length gives a value Dw/lw < 1:3. Radial needle roller bearings are intended exclusively for use as non-locating bearings. The given axial displacement path for bearings with an inner ring allows axial movements between the shaft and the housing. If necessary, wider inner rings are available to allow larger axial displacement paths. Our combined needle bearings are characterised by particularly high precision and efficiency. By integrating both bearings into one unit, combined needle roller bearings are often easier to press in and easier to handle than individual solutions.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

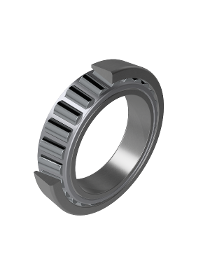

We manufacture our KIS tapered roller bearings in both single and double row designs. Since they can support both axial and radial forces, they can also withstand high loads. Due to their high precision they are suitable for shafts that are to be guided axially precisely (locating bearings) or if the bearing Tapered roller bearings are easy to adjust and disassemble, making them easy to mount and maintain. Tapered roller bearings are the perfect choice for applications where high loads or high precision are required. Our KIS tapered roller bearings are used in a wide range of applications, such as motors, compressors, construction machinery, machine tools and gearboxes. We will be happy to advise you on possible variants with different properties.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

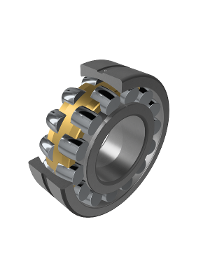

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quoteResults for

Cylindrical roller bearings - Import exportNumber of results

22 ProductsCountries