- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cycling shorts

Results for

Cycling shorts - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

Sharpener KSG processes the blades gently with short setup times thanks to its intelligent sharpening technology. The sharpening unit is positioned via a visor. Sharpener KSG guarantees rapid, reproducible sharpening and has a long service life thanks to the sharpening disks which are not actively driven. A counter is integrated for individual specification of sharpening cycles. Advantages Long service life thanks to non-actively driven sharpening discs Sharpening unit positioning via sighting tool Gentle processing due to clever sharpening technology Quick, reproducible sharpening Counter for the individual specification of sharpening cycles Short set-up times Simple operation Clear, robust technology

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Short loading times are a key feature of the Weber Slicer 702. It masters the special challenges when slicing short products with short cycle times and an endless product flow. The involute blade system reaches performances of up to 1,500 slices per minute in idle cut operation. Options: Loading arm feeder Trimmer End piece management

Request for a quote

HOCHRAINER GMBH

Germany

Selection of sample parts from a wide variety of industries Send us your part, and we'll show you how to reduce your costs. Short cycle times are guaranteed with 2-shift operation. Scheduled work is possible at any time thanks to flexible production conversion. Our comprehensive materials store keeps production times short. From individual part to series.

Request for a quote

KIRSCH KUNSTSTOFFTECHNIK GMBH

Germany

Folding is a method used for linear transformation of plate material. The material is selectively heated in certain areas and then cooled in special devices in ordert o stay in shape. The warming with quartz spotlights allow very short cycle times. Additionally we have a variety of folding benches that allow up to 4 bends per coat on a maximum working length of 2000 mm.

Request for a quote

FORBO SIEGLING GMBH

Germany

The Siegling Blizzard HC is a new benchmark in quality and speed when heating splices for Siegling Extremultus belts in the aramide and polyester lines as well as narrow Siegling Transilon belts. It’s easy to handle and has very short cycles. Automatic heating and cooling in one single tool prevents mistakes made during handling saves having to put the belts and splicing guide into a cooling clamp after heating is highly efficient due to short cycles delivers excellent splicing results with superior repeat accuracy

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

▪ Hygienic design for food, cosmetic and pharmaceutical applications ▪ Easy integration into automated processes due to compact design ▪ Length and weight savings compared to existing pumps ▪ Short cycle times ▪ Non-destructive dosing of solid containing materials with diameter of up to 20 mm ▪ Volumetric dosing and filling, regardless of viscosity ▪ For low to high viscosity materials ▪ Long service life even with abrasive and shear sensitive materials ▪ Continuous dosing, pulsation free ▪ Precise filling with high repeatability ▪ Linear relation between dosing volume and rotational speed ▪ Programmable suck-back prevents dripping or stringing of product ▪ FDA compliant elastomers ▪ Wetted components are autoclavable ▪ Stainless steel ▪ Optional flushing connection for optimum results with CIP ▪ Easy cleaning and maintenance due to quick assembly and disassembly options

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 420 - for tube-Ø from 4-20 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 660- for tube-Ø 6 - 60 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Accurate forming with fast tool change. Our type REB axial t form forming machines, with their compression power of up to 1,300 kN are particularly wellsuited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step userfriendly and fully programmable individually. We offer the option to equip our systems with electric or hydraulicnumerical drives. These forming processes can be completed stepwise in transfer system to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 645 - for tube-Ø 6 - 45 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Use by industry in robot-controlled applications Both versions of the GAV 8000 can be integrated into robot systems. Industrial robots are used almost everywhere in the production environment. They can be programmed to carry out various movements and can therefore be used highly effi ciently in combination with the GESIPA® rivet equipment. With the controlled, fast and secure production processes it is possible to achieve the following benefi ts by using a fully-automatic GAV combined with a multi-axle robot: • First rate precission • High effi ciency • Short cycle times • High fl exibility

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

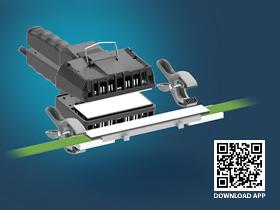

Technical information The Crimper-LS is an electropneumatic and flexible benchtop crimper for loose insulated Z+F ferrules in the cross-section range from 0.5 – 2.5 mm² (AWG 20 – 14) and crimping length from 6 – 12 mm. Additional tool kits are available optional for 0.34/4 mm² (AWG 22/12). The machine is characterized through a short cycle time and an easy tool change. A stripped wire can be fed in the ferrule directly. The crimping process is started by a footswitch.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

Technical data The AM 03 C is an electropneumatic, modular stripper-crimper for rapid and reliable processing of small, loose male and female contacts and for small cross-sections. The contacts are automatically fed by a feeding bowl. The adjustment of the stripping and crimping depth is manually. 50 different programs can be stored. Adjustment and programming is done with the touch display. The touch display shows all important data, functions and status. The machine may be adapted to different contacts and wires using the corresponding tools. Options Especially for short, turned contacts and cross sections Cost-effective entry-level model Fast cycle time Compact design Short infeed length

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The flexible PC-controlled high-performance circular sawing system PSU 450 A is designed for the utmost cost-effective production of small and large quantity runs. • The PSU 450 A features up to three servo-motorized axis to ensure a precise positioning with regard to length, mitre angle setting and output gripper unit • The material to be cut off is held by means of the output gripper unit. After the cut, the cut piece is removed from the working area in axial direction and put at a defined place. • Extraordinarily short cycle times due to the hydraulicallycontrolled saw stroke • A standard feature in the saw is an innovative, dynamic saw drive technology that ensures premium cutting results.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 22 ensures the precise, cost effective and efficient production of parts. The numerous automation solutions enhance its range of application; individual configuration is easy thanks to the modular design. The Hermle engineers have essentially designed and created this machine with space in mind. With the most efficient footprint possible, the C 22 offers maximum efficiency. And it goes without saying that large components can be machined, too. Nonetheless, the C 22 is ultra compact and ensures the necessary clearance for 5-side/5-axis machining. Short process cycles, quick workflows and the highest possible machine dynamics: The C 22 is designed to machine complex geometries with high accuracy and small tolerances. The circular tool magazine is integrated into the base body of the machining centre and can house up to 65 cutters; additionally, it is possible – as with almost all HERMLE machining centres – to adjust the operating system to the user.

Request for a quote

RUHLAMAT GMBH

Germany

Different aspects such as productivity, assembly operations, material flow, type variety, setup times and space conditions influence the concepts of linear transfer systems and form the foundation for many flexible automated solutions and linear transfer systems of modular construction. A high level of accessibility and the resulting low-maintenance design can count as additional advantages. ruhlamat offers varying base modules that can be adapted individually to the relevant circumstances in order to accommodate a wide range of requirements. Since production space is also becoming increasingly scarce and the assembly of products is becoming ever more challenging, ruhlamat offers a variety of solutions to maximise the spatial potential of the linear transfer systems. For example, the integration of the control cabinet in the base frame of the assembly cell, or the flexible back-pack variant on the "spine" of the cell, or as a stand-alone solution next to or above the linear...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IAI INDUSTRIEROBOTER GMBH

Germany

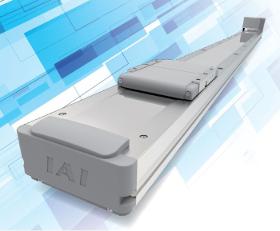

Toothed belt linear actuators from IAI are particularly suitable for high speeds, rapid accelerations and strokes between 200 mm and 3,200 mm. All actuators have a compact frame geometry and optimised cross section for maximum rigidity and load bearing capacity, making them resistant to twisting and deformation. IAI linear actuators with toothed belt drive are ideal for fast handling and positioning tasks in which high repeat accuracy with short cycle times are vital. The double slider option of the IF and the new IFA series gives the possibility to vary the distance between the two sliders. This increases the overhang load capability and allows a wide variety of configurations. Advantages at a glance ▸ High speed and acceleration ▸ High bending stiffness ▸ Long strokes ▸ Low maintenance ▸ Low noise

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

EleCylinder are electric cylinders with motor, encoder and integrated controller. These energy-saving actuators are extremely easy to use and operation via data input requires no complicated programming. Start and end points can be set to any position. Due to the high-speed movements, EleCylinders are ideally suited for short cycle times. Unlike pneumatic cylinders, they can also perform slow uniform speeds over the entire stroke. Even gentle starting or braking are no longer a problem. EleCylinder are repairable easily and have only a few maintenance parts.

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Temperature- and density volume conversation for liquids and gases. The UR06 is used to collect energy and material flows for gaseous, vaporous and liquid media. It can be connected to different types of volume, mass, flow, pressure, temperature and densitymeter. From the measured values ??and the parameters set by accepted rules of technology, the media properties are formed. For further processing of the measured and calculated values ??can be passed through variably configurable standard interfaces. Application • continuous measurements of pipeline liquids (mineral oil / Liquid gas) and gas • fuel consumption measurements of motors with supply and return acquisition including the temperatures • measurement of mineral oils used for accounting purposes • measurement in multi-product operation Characteristics • modular construction • Ethernet integrated • MBus and Modbus • simple operation • substantial data logger function • 24 Bit AD-converter • 2 metering points • short cycle...

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The travelling circular knife machine CCM 6 cuts rigid profiles and tubes accurately to length. The CCM 6 achieves very long processing times of several seconds for excellent "final trim quality" thanks to a standard servo linear drive for the tool carrier, and at the same time extremely short cycle times of less than one second for machining short parts at high line speeds. Added to this is the servo linear drive for circular knife feed with different feed speeds for different material sections, e.g. a gentle material penetration or knife exit with low feed to reduce burr formation. High speed ranges As far as the knife speed is concerned, we offer you outstanding possibilities of alternatively 2,000 – 6,000 rpm or 4,000 – 12,000 rpm. This means that there are no limits to the use of various types of circular knives, including clamping and grinding in continuous operation. Our product videos will give you an insight into the machining process.

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfunction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Interface for automatic components: optional Stud counter

Request for a quote

KÖSTER & CO. GMBH

Germany

Particularly suitable for short-cycle-stud welding Particularly suitable for thin work-pieces Stepless, exact adjustment of welding current and time Ideal for mobile tasks Designed for welding on building sits Plain text on LC-display Operating interface: choice between 4 languages: German, English, French, Italian Shielding gas equipment: standard Self-diagnosis: overheating, short circuit control, failure and malfuction of pilot arc Microprocessor controlled Constant current regulation Repeat cycle lock Steel housing, powder-coated Shielding gas equipment Interface for automatic components: optional Stud counter

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Profiles and sealing systems often require ventilation holes or mounting holes. Drilling equipment from Metzner carries out these tasks. We provide the following solutions adapted to your specific requirements: - In-line as an eccentric drilling station for regular drilling at equal distances - In-line as travelling drilling station for drilling at the same or variable distance - In-line as "drilling beam", which carries out all drillings for an entire sealing profile with variable distances in one operation - Off-line for drilling in combination with final trimming The machine is equipped with drilling spindles with very high speeds of up to 60,000 revolutions per minute. An exact drill hole is thus achieved in a short cycle time. The geometry of the drills ensures that the waste falls to the outside.

Request for a quote

AERO-LIFT VAKUUMTECHNIK GMBH

Germany

Be it bags, drums or boxes, the FLEX-LIFT from AERO-LIFT is able to transport almost everything. Loads weighing up to 35kg can easily be lifted, transported and rotated. That makes work quick, simple and ergonomically correct. Previous Next Benefit and features - ideal for loads up to 35 kg - back-friendly and ergonomically correct posture - one-handed control lever that supports the natural movement of the hand - short cycle times and quick stacking thanks to simple repetitive movements - quick-change coupling for split-second replacement of the suction cup - „Quick-Release“ function for a simple and quick release - integrated vacuum meter - integrated radio control (optional) Versions There are three handle versions to offer you the ideal handle solution for your handling. FLEX-LIFT standard version FLEX-LIFT Ergo Plus with angled handle FLEX-LIFT Variable adjusted variably Technical Data max. load bearing capacity: 35 kg max lifting...

Request for a quoteResults for

Cycling shorts - Import exportNumber of results

51 ProductsCountries

Company type

Category

- Cleaning machines, industrial (6)

- Metallurgy - machinery and installations (4)

- Automation - systems and equipment (2)

- 3D scanner (2)

- Food Industry - Machines & Equipment (2)

- Mechanical engineering - custom work (2)

- Metalworking - portable power tools (2)

- Wood veneer - machinery and equipment (2)

- Applicators for adhesives and glues (1)

- Dosing pumps (1)

- Drilling machinery (1)

- Electric and electronic components - machines for manufacturing (1)

- Gas extraction - systems and equipment (1)

- Lubricants, industrial (1)

- Machine tools - metal machining (1)

- Mechanical transmission - components (1)

- Metal industrial presses (1)

- Monitoring and control equipment (1)

- Pipes and tubes - ferrous metal (1)

- Presses, hydraulic (1)