- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting solutions

Results for

Cutting solutions - Import export

ZINSER GMBH

Germany

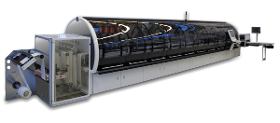

ZINSER GmbH offers leading bevel cutting technology known for its precision and reliability. Our systems are ideal for cutting mild steel, stainless steel and aluminum and offer customized solutions for different industrial applications. With the latest technology and high-quality workmanship, our bevel cutting machines ensure the highest efficiency and quality. ZINSER 4125B / 4026B / 4126B These premium bevel cutting machines offer excellent cutting quality and are perfect for demanding applications. They enable precise bevel cutting and are ideal for thick and thin materials. ZINSER 2315 / 2325 / 2425 / 2426 Our economical bevel cutting machines offer a cost-effective solution without compromising on quality. These models are ideal for companies that require precise cuts and high flexibility. ZINSER 1225 This compact cutting system combines the advantages of bevel cutting with a space-saving design.

Request for a quote

RIEDEL COMMUNICATIONS GMBH & CO. KG

Germany

The Tango TNG-200 is Riedel’s first fully-networked platform based on the AVB and RAVENNA/AES67 standards. With its own dedicated Intercom application, it can be turned into a cutting-edge and flexible solution for a variety of communications scenarios. Riedel’s Tango TNG-200 offers powerful processing capabilities, 2 integrated Riedel Digital Partylines, 2 RAVENNA/AES67 and AVB compatible ports, 2 Ethernet ports, 1 option slot, and redundant power supplies. Tango TNG-200 is 1.5 RU high and features a low mounting depth and a low noise design. Most Riedel current and legacy Intercom panels, including the new 2300 Smartpanel, are fully compatible with Tango.

Request for a quote

RIEDEL COMMUNICATIONS GMBH & CO. KG

Germany

The Tango TNG-200 is Riedel’s first fully-networked platform based on the AVB and RAVENNA/AES67 standards. With its own dedicated Intercom application, it can be turned into a cutting-edge and flexible solution for a variety of communications scenarios. Riedel’s Tango TNG-200 offers powerful processing capabilities, 2 integrated Riedel Digital Partylines, 2 RAVENNA/AES67 and AVB compatible ports, 2 Ethernet ports, 1 option slot, and redundant power supplies. Tango TNG-200 is 1.5 RU high and features a low mounting depth and a low noise design. Most Riedel current and legacy Intercom panels, including the new 2300 Smartpanel, are fully compatible with Tango. The sunlight readable, high-resolution, full-color TFT display ensures perfect readability at all times, extending the range of possible applications and providing maximum ease of use. The intuitive front panel controls enable users to easily recall presets and adjust audio levels. Riedel’s Tango TNG-200 is an efficient...

Request for a quote

WEBER ULTRASONICS AG

Germany

For agile cutting tasks in close quarters, small lots or prototyping, the HSM Hand Cutting Module is the perfect solution. This ergonomically shaped tool is splash-proof and convinces with durability. The HSM is always configured to your specific needs and comes with a Sonotrode tailored to your task.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers advanced pipe cutting technology known for its precision and efficiency. Our systems are ideal for cutting cylindrical and polygonal pipes made of mild steel, stainless steel and aluminum. With the latest technology and high-quality materials, our machines ensure the highest cutting quality and reliability for industrial applications. ZINSER 1304 / 1306 These specialized pipe cutting machines offer precise and fast cuts. The ZINSER 1304 and 1306 models are perfect for processing pipes with complex geometries and different materials. They offer excellent results for breakthroughs, recesses and end processing. Advantages of ZINSER pipe cutting machines Highest precision: Exact and repeatable cuts thanks to the latest control technology. Versatility: Suitable for different pipe materials and diameters. Efficiency: Cost-effective cutting solutions thanks to innovative technology and robust construction. Durability

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers you top-class CNC cutting systems that impress with their outstanding quality, reliability and efficiency. Our systems include oxy-fuel, plasma and laser cutting technologies that are optimized for mild steel, stainless steel and aluminum. With customized solutions and innovative technology, our machines are ideal for demanding production requirements. Premium cutting systems 4000 series The ZINSER premium series (models 4025B, 4125B, 4026B, 4126B) stands worldwide for excellent cutting quality and machine reliability. These machines are perfect for oxy-fuel, plasma, laser, bevel cutting as well as drilling and threading. Economical cutting systems 2000 series Our economical models (ZINSER 2315, 2325, 2425, 2426) are powerful and robust. They offer precise cuts and high flexibility for various applications, including simple and bevel cuts and pipe processing.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers comprehensive software solutions for flame cutting machines that are known for their user-friendliness and efficiency. Our software is designed to optimize the entire cutting process, from the creation of the CAD drawing to the finished flame-cut part. With the latest technology and practical functions, our software solutions improve the productivity and accuracy in your production. ZINSER MCC 20 The ZINSER MCC 20 is our latest cutting software that offers easy operation and a wide range of functions. With this software you can import DWG and DXF files and choose from over 140 standard figures. The MCC 20 enables automatic nesting, drilling with ZINSER Hole technology, as well as the use of a calculation module and an extensive database.

Request for a quote

ZINSER GMBH

Germany

High-precision plasma cutting machines from ZINSER - efficient cutting solutions for all applications ZINSER GmbH offers a wide range of high-precision plasma cutting machines that are known for their outstanding cutting quality and efficiency. Our systems are specially designed to cut mild steel, stainless steel and aluminum with the highest precision. Thanks to the latest technology and a robust design, our plasma cutting systems ensure maximum productivity and reliability in industrial production. ZINSER 4025B / 4125B / 4026B / 4126B These premium plasma cutting machines offer excellent cutting quality and reliability for demanding applications. They are ideal for cutting thick and thin materials and are suitable for both simple and complex cutting tasks. ZINSER 2315 / 2325 / 2425 / 2426 Our economical plasma cutting machines offer a cost-effective solution without compromising on quality.

Request for a quote

ZINSER GMBH

Germany

As a pioneer in autogenous welding, ZINSER has been offering cost-effective solutions for the use of acetylene and other gases for over 120 years. Our autogenous CNC cutting machines are known worldwide for their reliability, cutting quality and robustness "Made in Germany". As an innovation-oriented company, ZINSER is constantly evolving to offer its customers individual cutting solutions. We therefore offer combined flame cutting and plasma machines in 3 ranges (compact, economical, premium) as well as many options for our autogenous cutting machines: beveling with triple torch, drilling, marking, pipe cutting, etc.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers an extensive range of accessories to optimize your flame cutting machines. Our accessories are designed to maximize the efficiency and performance of your cutting processes by allowing you to optimally adapt your machines to your specific requirements. Plasma systems Our plasma systems offer precise and fast cutting of metals and are ideal for various applications. With our plasma systems you can achieve clean and precise cuts with minimal material loss. Cutting tables with and without extraction Our cutting tables offer an effective solution for air purification and dust extraction during the cutting process. They are available in different designs to meet the requirements of different cutting applications. Extraction systems Our extraction systems are specially designed for plasma, oxyacetylene and laser cutting. They offer high filtration performance and help improve air quality and reduce maintenance costs.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers first-class environmental technology solutions to complete your cutting systems. Our extraction and filter systems have been specially developed for applications such as plasma, oxyacetylene and laser cutting and set new standards in filtration performance and productivity. We offer you tailor-made solutions for systematic air purification to maximize the efficiency and safety of your cutting processes. Extraction and filter systems ZINSER extraction systems offer the highest performance and effectiveness. Our filter systems are available in various sizes and can be tailored to your specific requirements. They offer plug-and-go functionality, a closed design, quiet operation and high-performance filter cartridges that ensure improved cleaning efficiency and energy cost savings. ZINSER cutting tables Our cutting tables are the optimal solution for air purification during the cutting process.

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

MiniCut - The flexible solution for precise cutting to length of PIK trunking The MiniCut offers the ideal solution for mobile use thanks to its compact design and practical transport handles. The manual drive enables energy-saving work, while the machine can be converted to hand-hydraulic or mains or battery-powered drives for maximum flexibility. Advantages: Versatile processing: For PIK trunking 15/15 to 60/60 made of steel and stainless steel. Economical: Time and cost savings thanks to precise work and reduced material waste. Safety: Effortless handling and burr-free cutting for safe application. Flexibility: Mobile use, regardless of location. Durability: Regrindable cutting plates for a long service life. Compatibility: Can be extended with manual hydraulic or electric hydraulic units. Precise alignment: Including infeed aid for precise work with 90° cuts.

Request for a quote

RUHLAMAT GMBH

Germany

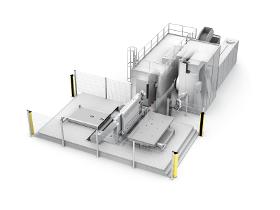

The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest accuracy and unmatched productivity at an unbeatable price-performance ratio. The system can be designed to perfectly match your needs: sheet to sheet (S2S), reel to sheet (R2S), or reel to reel (R2R). This flexible solution offers the most economical way to produce RFID inlays for ID documents in large quantities. You get unrivalled real-world throughput: up to 4,050 antennas/hour as antenna embedding machine and up to 2,000 finished RFID inlays/hour as inlay manufacturing line. The WCE2000 is available in virtually unlimited configurations. Wire coil embedding, module pick & place, soldering, and testing are the main features that can be integrated to build a tailor-made solution. Punching, sheet cutting, handling and collation of additional layers, and other features complement the system to a complete inlay manufacturing line. The possibility to combine all of...

Request for a quote

RUHLAMAT GMBH

Germany

With the ruhlamat FILUS and the WCE2D, you can achieve large-area and precise wire-embedding results. In addition to wire embedding, pick-and-place handling and cutting, this 2D wire-embedding solution is also precise at soldering and dosing. 3D Wire embedding technology The WCEvario3D captivates through its flexible application options: From flat surfaces to concave and convex contours, the flexible robotic arm with a state-of-the-art wire-laying head and constant pressure-force control can handle all dimensions. 2D Wire embedding technology 2D Wire embedding technology With the ruhlamat FILUS and the WCE2D, you can achieve large-area and precise wire-embedding results. In addition to wire embedding, pick-and-place handling and cutting, this 2D wire-embedding solution is also precise at soldering and dosing. 3D Wire embedding technology 3D Wire embedding technology The WCEvario3D captivates through its flexible application options: From flat surfaces to concave and...

Request for a quote

STARRAG GMBH

Germany

In the aviation industry, there is an increasing trend towards larger and larger monolithic structural components. The ECOSPEED series, featuring a horizontal spindle and a vertical pallet arrangement, has been specially developed for highspeed machining of these large structural aluminum components. A pallet transport system feeds pallets to the machine, the storage station and the loading/unloading station. The innovative Sprint Z3 parallel kinematic machining head, provides the user with the optimum 5axis simultaneous machining process. At a maximum cutting volume of up to 8,000 cm3/min, the machine concept is the world's most productive solution for cutting aluminium structural components, drastically cutting both production times and costs.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp's continuous saws are a tried-and-tested solution for plants with highest outputs. The saw throughput does not depend on the number of cuts and is therefore superior to other cutting solutions, particularly for large master boards. Continuous saws also permit in-line quality grading. This means that the combined sanding and saw line is able to deliver sorted stacks of nished boards from the master boards in a single stage of work. This allows investment and operating costs to be minimised. The cut-to-size saws may be combined in-line with a sanding machine or set up separately just as a cutting system Features and functions Continuous saws for longitudinal and horizontal cuts Scoring unit and main saw blade for top-quality edges Reliable guiding of the board using chains and/or rollers to ensure accurate cutting Trimming of the edges directly by the tool, no additional conveyors and follow-up work required

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

The coating of the newly developed CopyMax®2 insert from LMT Kieninger is Nanomold Gold, which is already an indication of top performance in mold and die making. The copy milling insert itself has a new construction design. It has improved cutting and material properties as well as a fully functional second cutting edge. When the first cutting edge is worn, the insert can be turned over and re-used with the same long tool life. Benefits: Identical geometry to the highly efficient WPR-AR copy milling insert. - The stable cutting edge and proven Nanomold Gold coating double the service life per cutting edge - 4 times higher tool life possible by using the 2nd cutting edge. - Highly economic solution for more than 70 % of your applications in forming technology, energy technology and mechanical engineering.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAVER NIAGARA GMBH

Germany

The NIAGARA® M-Class constitutes the optimum solution when many cut points in the fine and very fine range are required and, in addition to that, most accurate cuts are of decisive importance. There are various fields of application that exist for the linear motion swinger. To be precise, the screening system can be employed for the classification of industrial minerals, food, chemical products, ores and metals. The dynamic loads of the machine are reduced to a minimum by an isolating frame. As a result the vibrations transferred into the structure can be prevented. Depending on the required application, the exact adjustable rotation speed and amplitude ensures an optimum screening result. Accelerations are possible between 2 g for the production of abrasive materials - or up to 4,5 g for the dry mortar or silica sand industry. The multiple-deck screening machine NIAGARA® M-Class is offered in eight different sizes, the number of decks and technical specifications depends on the...

Request for a quoteResults for

Cutting solutions - Import exportNumber of results

19 ProductsCountries

Company type