- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting of pipes

Results for

Cutting of pipes - Import export

SCHELLEN & FLACK GMBH

Germany

Applications of structural steel hollow sections include hoists, frame structures, and beams and columns. With structural steel hollow sections, you can significantly reduce the weight of your steel structures and achieve savings in material and manufacturing costs – without limiting freedom in design.

Request for a quote

SCHELLEN & FLACK GMBH

Germany

Tubes made of aluminum offer various advantages, such as corrosion resistance, low weight and high stability. Aluminum tubes are very durable and can be recycled without loss of quality. A wide variety of constructions can be realized with tubes made of aluminum.

Request for a quote

SCHELLEN & FLACK GMBH

Germany

Whether chassis applications with high dynamic stress and safety-relevant functions or lightweight solutions for the highest crash requirements. Our claim is to find the technically and economically best solution for your individual requirements

Request for a quote

SCHELLEN & FLACK GMBH

Germany

Stainless steel tubes have become an indispensable part of everyday life. We hold onto them on the bus or use them as railings in houses. In the furniture industry, stainless steel tubes are used as wardrobe rods and as components for furniture. In their largest form, they serve as pipelines for oil and gas.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Clean, efficient, versatile. transfluid's knife cutting method is ideal for postbending cuts. Even with extreme geometries it is possible to have perpendicular cuts with sharp edges. In both cases both chips can easily be detected in the process. Extreme requirements are also not a problem, as up to two blades can be used. An internal mandrel can also optimise the process.

Request for a quote

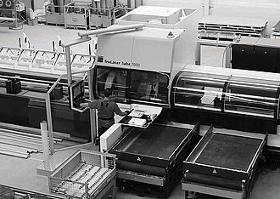

ZINSER GMBH

Germany

ZINSER GmbH offers advanced pipe cutting technology known for its precision and efficiency. Our systems are ideal for cutting cylindrical and polygonal pipes made of mild steel, stainless steel and aluminum. With the latest technology and high-quality materials, our machines ensure the highest cutting quality and reliability for industrial applications. ZINSER 1304 / 1306 These specialized pipe cutting machines offer precise and fast cuts. The ZINSER 1304 and 1306 models are perfect for processing pipes with complex geometries and different materials. They offer excellent results for breakthroughs, recesses and end processing. Advantages of ZINSER pipe cutting machines Highest precision: Exact and repeatable cuts thanks to the latest control technology. Versatility: Suitable for different pipe materials and diameters. Efficiency: Cost-effective cutting solutions thanks to innovative technology and robust construction. Durability

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 80 x 3 mm Shortest separation length: - 70 mm (without pull apart) - 100 mm (with pull apart) Cycle time: 5-10 sec. (depending on material, diameter, wall thickness and cutting length)

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 105 x 3 mm Shortest separation length: - 100 mm (without pull apart) - 170 mm (with pull apart) Cycle time: 5-10 sec. (depending on material, diameter, wall thickness and cutting length)

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 50,8 x 2,5 mm Shortest separation length: - 25 mm (without pull apart) - 55 mm (with pull apart) Separation efficiency: up to 2,000 pcs per hour

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

The advantages to you: no more deformation of roundness when cutting bends on site easier extension-pipe/tiered pipe bend construction appealing visually pickled surface All of our pipes and pipe bends (both unannealed and annealed) are made of the following material: stainless steel pipe, material no. 1.4301 (AISI 304) longitudinal seam welded pipes hot rolled & cold rolled coils, unannealed, with or without pickling (W1) Make: IltaInox and/or Marcegaglia

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers an extensive range of mobile equipment for cutting and welding metal. Our products are designed to offer the highest precision and flexibility wherever they are needed. From pipe cutting devices to hand-held flame cutting machines to portable oxy-fuel technology - we have the solution for your requirements. RSV pipe cutting devices Our mobile pipe cutting devices enable the simultaneous cutting and beveling of steel pipes. Thanks to the quick-clamping device, they can be fixed in any position, offering maximum flexibility and efficiency. The cutting torch can be rotated by 45°, adjusted in height and sideways and can optionally be motorized. Hand-held flame cutting machines ZINSER's mobile hand-held flame cutting machines are designed for daily use. They offer precise and reliable cuts with maximum user-friendliness. ZINSER oxy-fuel technology ZINSER has been involved in the economical use of acetylene and other gases for over 100 years.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers you top-class CNC cutting systems that impress with their outstanding quality, reliability and efficiency. Our systems include oxy-fuel, plasma and laser cutting technologies that are optimized for mild steel, stainless steel and aluminum. With customized solutions and innovative technology, our machines are ideal for demanding production requirements. Premium cutting systems 4000 series The ZINSER premium series (models 4025B, 4125B, 4026B, 4126B) stands worldwide for excellent cutting quality and machine reliability. These machines are perfect for oxy-fuel, plasma, laser, bevel cutting as well as drilling and threading. Economical cutting systems 2000 series Our economical models (ZINSER 2315, 2325, 2425, 2426) are powerful and robust. They offer precise cuts and high flexibility for various applications, including simple and bevel cuts and pipe processing.

Request for a quote

ZINSER GMBH

Germany

As a pioneer in autogenous welding, ZINSER has been offering cost-effective solutions for the use of acetylene and other gases for over 120 years. Our autogenous CNC cutting machines are known worldwide for their reliability, cutting quality and robustness "Made in Germany". As an innovation-oriented company, ZINSER is constantly evolving to offer its customers individual cutting solutions. We therefore offer combined flame cutting and plasma machines in 3 ranges (compact, economical, premium) as well as many options for our autogenous cutting machines: beveling with triple torch, drilling, marking, pipe cutting, etc.

Request for a quote

F.E.S. GMBH

Germany

Vacuumfilters are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Compact size Excellent filtration results Low installation effort Low maintenance requirements Affordable price Optional configuration without consumable filter fleece, with continuous filter belt, and washing device Significantly lower consumption of filter fleece compared to gravity filter systems during challenging filtration tasks and fleece operation Operating Principle: The contaminated cutting fluid flows through a piping system (1) and an inlet distributor (11) into the dirt chamber (2) of the underpressure filter tank.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

Universal, precise and fast - these are the performance features of the PSU 450 H semi-automatic mitre saw for cutting metals. Designed for cutting profiles, pipes and solid material in metal and comparable materials, this machine is specifically designed to address the needs of locksmiths and metalworking shops. The mitre setting is equipped with convenient fixed stops at 90°, 45° and 30°. The 450 mm diameter saw blade used offers a wide cutting range - also for mitre cuts. The heart of the PSU mitre saw unit is the worm gear unit with EISELE shock-absorbing feature, produced in-house. It is heavy duty and provides for a smooth, low-vibration running of the saw, which, of course, has a positive impact on the quality of the cutting surface and the blade life.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ORBITEC GMBH

Germany

A precise 90° saw cut is a basic requirement for orbital weld preparation. Robust saws for all wall thicknesses Powerful drive motor Uniform and easy feed control by means of handwheel Different chamfering blades mountable Right-angled saw cut 4, 5 or 6 clamping jaws made of stainless steel as well as reducing jaws Due to concentric clamping no deformation with thin-walled pipes Also for cutting off pipe bends Quick-release fastener for easy changing of saw blades Chip removal during cutting by means of integrated brush Convenient adjustment of plunge depth by means of feed wheel Technical Data: Size range in mm: OD 6 – 220mm Size range in inch: 0.236″ – 8.661″ Wall thickness: 1 – 8mm Electric drive: Single-phase AC motor Mains voltage (input): 200/220VAC (50/60Hz) Power: 1000W / 4.5A Protection class: II Speed control: 6-step control Weight: 47 - 77kg Package includes: Tube saw with electric drive One saw blade One bottle of saw blade lubricating oil

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTISONIC 6300 P is a portable, battery-powered ultrasonic clamp-on flowmeter for temporary flow measurement of (non-)conductive liquids. It can be used at virtually any location and without process interruption or need to cut pipes. Due to its flexibility, the meter is equally suited for comparative measurements on stationary measuring equipment (e.g. pumps, flowmeters etc.) or for use as a short-term replacement of faulty devices. The OPTISONIC 6300 P consists of a combination of one or two clamp-on sensors and one handheld electronic signal converter. The robust clamp-on rail can be easily attached to almost any pipe up to DN1500/160". The readings of the meter are shown on the handheld LCD and are stored in the integrated memory for data logging. In addition, all readings can be transferred to a PC via the included USB stick in order to further analyse or store the data.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Cellular wheel sluices Cellular wheel sluices are used as discharge devices under filters, cyclones and silos, as well as for channelling materials into pneumatic conveying systems. In a special tested version, however, these can also be used at the same time for the explosive decoupling of complex plant systems in the sense of the ATEX regulations. Multi-cutter The multi-cutter is ideally suited for the chopping up of paper or plastic waste strips as well as veneer residues in extraction pipes. It works with a set of fast-rotating, but air-permeable blades. The connection diameter is DN 160 and the motor has a rated drive power of 0.75 KW. In order to be able to definitely assess the usability for the application, it is advisable to provide us with representative material samples. The assessment is also often proven by pilot plant trials. The advantage of this is that the degree of chopping can also be determined. ATEX non-return valves (EX) Non-return valves are passive decoupling elements in pipelines for preventing dust explosion effects from running in the opposite direction to the conveying direction. The non-return valves are type-tested protective systems in accordance with directive 94/9/EC, better known under the synonym ATEX 95. Function In normal operation, the top-mounted flap swims on the air stream in the housing of the non-return valve and in this way is held open. At a standstill the valve flap closes under its own weight and rests on the diagonally cut inflow pipe. If an explosion occurs behind the non-return valve, the air flow direction is reversed due to the increased counter-pressure. This causes the flap to close. The valve flap is additionally pressed against the inflow pipe by the pressure of the explosion, thus reliably sealing the pipeline against an explosion backdraught. These non-return valves function without external energy. The RSK and BPF-M series are available in the sizes DN 160, 200, 250, 280, 315, 355, 400, 450, 500, 560, 600, 630, 710, 800, 900 and 1,000. The two series differ in that they have different versions and application possibilities. The non-return valves, as type-tested protective systems, are sold through Brilex Gesellschaft für Explosionsschutz mbH, Hinterm Gallberg 15-17, D-59929 Brilon; www.brilex.de

Request for a quote

ANT APPLIED NEW TECHNOLOGIES AG

Germany

The mini MACE is suited for, for example, the cutting and opening of pipe bombs, hand grenades or potentially hazardous objects such as unconventional explosive devices in the form of fire extinguishers and cases. mini MACE combines an abrasive mixing unit and a high-pressure pump in a single casing. The working pressure of the unit, which is driven by an internal combustion engine, is 6525 PSI (450 bar). The mini MACE was developed as a mobile penetration and cutting tool. An autarkic complete system equipped with internal combustion engine, abrasive mixing unit (AMU) and high pressure pump for accessing and deactivating IEDD (Improvised Explosive Device Disposal). It could be also used in the industrial sector for e.g. opening tanks.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Technical plastics for industry are a further speciality of IBK. We produce plastic parts to your specifications (ISO, CAD, drawing) for all temperature ranges and with specific chemical resistance. Whether unusual, complex or just simple forms – we turn, inject, saw, drill or mill, whatever you require. We supply semi-finished products as round bars, plates, pipes, rods, profiles or individual cuts, rolls, rollers or wheels with or without coating. Furthermore finished parts, such as protective systems for safety at the workplace in electronic applications. We process all types of plastic, from polyamide to hard PVC through to GRP/FRP. Semi-finished parts: Plates, Blocks, Full rods, Hollow rods, Pipes, Cut pieces Finished parts Cut and processed (turned, milled, drilled etc.) to drawing, sketch or sample, such as - Wheels, Rollers, Bearing bushes, Thrust rings, Bands, Sleeves, Strips

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 161i neo is the latest high-precision plasma cutting system for the cutting range between 0.5 mm and 50 mm. Equipped with the soft-switch inverter technology, it offers a wide range of possibilities for cutting and marking thin and medium-sized sheets. It meets the requirements of the metal and container construction industries, the engineering and automotive industries and many other sectors. The HiFocus 161i neo can be combined with 2D as well as 3D CNC-controlled guiding systems, i.e. gas cutting systems, robots and pipe cutting systems.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 360i neo is one of the most flexible and most powerful high-precision plasma cutting units. Its wide cutting range from 0.5 mm to 80 mm means a considerably higher flexibility. The latest inverter technology allows the highest marking quality and functionionality on the market. The HiFocus 360i neo is ideally suited for steel service centers, steel producers and distributors because it can be combined with 2D or 3D CNC-controlled guiding systems like gas cutting machines, robots and pipe cutting machines. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 280i neo is one of the most flexible and most powerful high-precision plasma cutting units. It covers a cutting range from 0.5 mm to 70 mm. The latest inverter technology allows the highest marking quality and functionality on the market. The HiFocus 280i neo is ideally suited for steel service centers, steel producers and distributors.It can be combined with 2D or 3D cnc-controlled guiding systems like gas cutting machines, robots and pipe cutting machines. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient. The HiFocus 280i neo is available as standard with the Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

Request for a quoteResults for

Cutting of pipes - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Cutting - machine tools (4)

- Pipes and tubes, cast iron (4)

- Plasma cutting machines (3)

- Shearing machine tools (3)

- Machine tools, cutting - parts and accessories (2)

- Pipes and tubes - ferrous metal (2)

- Sawing machine tools (2)

- Flowmeters (1)

- Industrial equipment hire (1)

- Plastics - industrial products (1)

- Pneumatic tubes - systems (1)

- Power saws, portable (1)