- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting fluid

Results for

Cutting fluid - Import export

F.E.S. GMBH

Germany

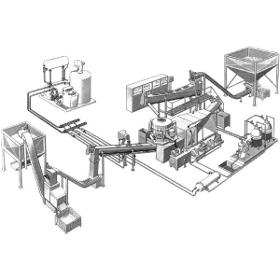

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

F.E.S. GMBH

Germany

Vacuumfilters are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Compact size Excellent filtration results Low installation effort Low maintenance requirements Affordable price Optional configuration without consumable filter fleece, with continuous filter belt, and washing device Significantly lower consumption of filter fleece compared to gravity filter systems during challenging filtration tasks and fleece operation Operating Principle: The contaminated cutting fluid flows through a piping system (1) and an inlet distributor (11) into the dirt chamber (2) of the underpressure filter tank.

Request for a quote

F.E.S. GMBH

Germany

Pressure belt filters are used for cleaning contaminated cutting fluids in metal processing and rolling mill applications. Cleaned cutting fluids have longer lifespan, improve surface quality, and contribute to heat dissipation at the processing or forming point. Advantages: High throughput capacity No backwashing during regeneration Easy discharge of filter cake Short regeneration time Compatible with various plastic filter belts High and low-pressure rinsing system Affordable price Operation: The F.E.S. pressure belt filter addresses the need for filtration without disposal issues by utilizing a standard feature of a circulating plastic filter belt. A filter belt cleaning device is integrated into the head section of the belt filter. The closing mechanism of the sealing flaps, lowered pneumatic cylinders, and movable protective covers ensure a low height for easy installation and operation.

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

50 lint-free, highly absorbent wipes for cleaning plastic surfaces and screens. • Lint-free, highly absorbent fleece wipes • For cleaning plastic surfaces and screens • Ideal for use with DURABLE cleaning fluids • Cut to size individually in 145 x 197 mm format • Contents: 50 wipes

Request for a quote

F.E.S. GMBH

Germany

Automatic Precoat Filter are used for the cleaning of contaminated cutting fluids in metal processing and rolling mill applications. Clean cutting fluids lead to longer tool life, improved surface quality of workpieces or rolled goods, and efficient heat dissipation at the processing or forming point. Advantages: Fully automatic operation Excellent filtration results Compact size Low maintenance requirements Full-flow filtration Dry cake discharge with minimal carryover of cutting fluid No fleece consumption Maximum lifespan of cutting fluid Operating Principle: The cleaned cutting fluid is supplied to the filter system pump (1) from the clean tank (2) of the processing machine. The contaminated cutting fluid is introduced into the dirt tank (3) of the cake filtration system through inlet channels or lifting stations. The internal processing of the system consists of four steps: “Cake Formation,” “Filtration,” “Regeneration,” and “Sludge Treatment.”

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Suction Pumps are self-priming following the initial priming, and operate according to the bypass duct principle. We recommend pump models featuring bronze body elements for pumping water without anticorrosion additives. The dimensions are based on standard specification EN 12157. Impellers: open Fluids: coolants, cooling/cutting oils, fuel oil, water (with anticorrosive additive) Volumetric delivery: up to 52 l/min Delivery head: up to 16 m Please contact us for delivery quantity

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Series V 600 - 1100 IS The HEINKEL Vertical De-oiling Centrifuge V 600 – 1100 IS is designed and built for the separation of cutting fluids and coolants from steel, cast and metal chips. Special properties for the customer’s benefit: Recovery of liquids and oil from chips produced by processing centres and from plastic pellets Simple and rugged design

Request for a quote

FIBALON GMBH

Germany

The use of filtration materials and systems in the field of industrial applications and the use of filter in the producing industries claim filter as well as filter systems on the highest degree. New fiber types with different surface modifications in a new combination, united in the innovative polymer fiber filter FIBALON®tool, offering unique and outstanding filtration results. By optimizing our developed dynamic fiber fixation DyFix® and a particle-dependent fiber geometry, we can now also offer our worldwide unique polymer fiber filter for the industrial use. For example in metal band saws to protect the pump or for the treatment of cooling lubricants and also for cutting fluids (e.g. in CNC machines) is FIBALON®tool with its highly durable special fiber combination an inexpensive alternative with improved filtration efficiency compared to conventional systems such as centrifuges or belt filter systems.

Request for a quoteResults for

Cutting fluid - Import exportNumber of results

9 ProductsCountries

Company type