- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- condensation separators

Results for

Condensation separators - Import export

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed air preparation helps to prevent malfunctions on pneumatic components and increases their service life. Machine failures and downtimes are reduced. Whether compressed air preparation, regulation or cleaning, we have multi-part service units, from pressure regulators, filter controllers, oilers, condensate diverters and oil-water separators to system expansions and various accessories as well.

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Explosionproof/flameproof gas preheater EEx d -ATEX und IECEx zertifiziert In general a cooling down takes place at expansion of gases whilst a heating takes place at compression. Typical gases are carbon monoxide, natural gas and air. The temperature change, which occurs at expansion of gas or gas mixture from a high to low pressure i.e. after a gas pressure control is called Joule-Thomson effect. In order to prevent the effects of Joule-Thomson as icing or condensate separation, the gas will be heated up before expansion. The gas pre heaters are suitable for all kind of gaseous media (i.e. air, natural gas, technical gases, fuel gas) and low flow process applications, suitable for pressures up to 300 bar. The “Cast electric heaters” type flameproof electrical gas pre heaters are certified for use in zone 1 or 2 hazardous area, custom built to meet client specification. The gas pre heater consists of a process tube coil and an electrical heating bundle, casted in aluminium. The process gas flows through the tube coil and is heated by the aluminium block that provides the heat transfer. This indirect electric heating gives an accurate control of the process and eliminates pressure vessel design and associated costs.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

OSMO MEMBRANE SYSTEMS GMBH

Germany

Condensate polishing During the production process of basic organic chemicals, very often condensates occur as byproducts, which have to be treated before dumping or recycling into production process. The condensate occurring at the product process of caprolactame contents for example ammonium sulfate and caprolactame. The loss of these products instead of recycling would not only mean a reduction of the process recovery, but also very high costs for waste water treatment. These condensates can be concentrated by a reverse osmosis plant. Because of the high salt retention rate of the reverse osmosis membrane, nearly all contents of the condensate are separated and can be brought back to the production cycle. The filtered permeate can be dumped into the municipal waste water system without hesitation. In some cases, the recirculation of the separated contents is not appropriated. In this context, reverse osmosis helps reducing the volume of the accruing condensate. The remaining conden

Request for a quote

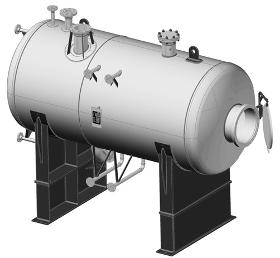

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Pressure vessel design Volume according to customer requirements OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement ACCESSORIES on demand level indicators condensate drainage systems sump heating GENERAL & FUNCTION The condensate tank type VKAB collects liquids and condensates, which are generated during the cleaning of gas in liquid separators. The condensates are discharged from the separators into the tank and serve for pressureless intermediate storage. The design is carried out as a steel welded construction in a horizontal design and is designed as a pressure vessel with 3 bar. QUALITY MANAGEMENT DIN EN ISO 9001 certified

Request for a quoteResults for

Condensation separators - Import exportNumber of results

13 ProductsCountries

Category