- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- condensate systems

Results for

Condensate systems - Import export

BEKO TECHNOLOGIES GMBH

Germany

The generation of compressed air is always connected with the formation of condensate. In most cases, this condensate contains oil, is contaminated with dirt particles and spreads out in the entire compressed-air system. A system problem which can result in damage and additional costs. The BEKOMAT drains condensate in the compressed-air system in an electronically level-controlled manner. More than 3,000,000 installations worldwide make it the industrial standard for reliable and cost-effective condensate drainage.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

INOX VERTRIEBS GMBH

Germany

INOX fuel system cleaner can be used for all gasoline engines. It dissolves dirt and resin buildup in the entire fuel system and reliably removes all coking residues and soot deposits. This increases the service life of the engine. optimizes emissions values binds condensation Dissolves contamination and gumming in the entire fuel system Reliably removes all coking residues and soot deposits ensures clean and powerful combustion removes moisture and condensation from the entire fuel system lubricates and protects the upper cylinder area increases the lifespan of the engine

Request for a quote

INOX VERTRIEBS GMBH

Germany

INOX Petrol Power is suitable for all normal and premium petrol engines. It dissolves dirt and resin buildup in the entire fuel system and reliably removes all carbon residues and soot deposits. The service life of the engine is increased. Dissolves contamination and gumming in the entire fuel system clean combustion more gasoline power for all normal and premium petrol engines Reliably removes all carbon residue and soot deposits ensures clean and powerful combustion regulates the PH value in the fuel system improves exhaust emissions removes moisture and condensation from the entire fuel system lubricates and protects the upper cylinder area increases the lifespan of the engine

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— Secure use of condensate in steam boiler systems — Decreases in energy and water consumption due to reduced quantities of make-up water — Minimisation of flash steam losses, desalting and blowdown quantities; reduced consumption of chemicals — Reduced corrosion potential in the steam condensate system when using high-pressure condensate systems

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the cooling of blow-down water and the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Rigorous compliance with official requirements thanks to automatic operation — Fast and easy assembly, requires just a small number of connections before it can be used

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For the recovery of heat from desalinated water/condensate — Increase in system efficiency of up to 2% — Reductions in fuel, cooling water and waste water costs — Fast and easy assembly, requires just a small number of connections before it can be used Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

You require a mobile steam plant or you want to install a steam plant outside your plant building? Then the complete installation within a container is the ideal solution for you. The container steam plant contains all the required components – from the water treatment plant through to the steam trap. - CERTUSS steam generator - CERTUSS CVE supply unit - Feed water treatment - Steam distributor - Pressure reducer station - Clarification valve - Steam dryer - Condensate elevating system - Steam trap - Interior lighting of the container - Insulated pipe installation in the container - Emergency-off switch - Steel door or uPVC door - High-quality stainless steel wall with insulation - Outside coating as required The installation and commissioning of the container plant at the customer is on request either carried out completely or only partially (if an external installation company is used) by our customer service.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The H2Smart™ is an integrated sampling system designed to measure hydrogen content with high accuracy in nitriding and nitrocarburizing atmospheres and to calculate the parameters necessary for process control. Its unique measuring cell design and advanced electronics eliminate the need for a reference gas cell, thus simplifying the installation and usage. Moreover, the measuring cell is maintained at a set temperature to protect the system from condensation and contamination during nitrocarburizing and post oxidation processes. An integrated sampling pump with variable output insures reliable flow through the measuring cell. The sampling flow is continuously measured via an integrated mass flow meter, and, if necessary, the flow is adjusted by changing the pump output. In this manner, the closed-loop flow control assures reliable H2 measurement and thus accurate nitriding and nitrocarburizing control.

Request for a quote

DELTA TECHNIK FILTERSYSTEME GMBH

Germany

Our mobile ultra fine filter system M 120 is the processing machine for larger oil volumes. Its two hard chrome-plated housings can filter up to 2.100 liter per hour of flow. The robust construction, the easy operation, and the possibility of using it in continuous operation without supervision makes it an ideal tool of a preventive maintenance strategy for large units. Even while filling new oil in larger systems it eliminates condensed water and foreign particles reliably. The high flow guarantees a short amortization time due to cost savings in fresh oil, oil changes, and repairs. 230 V-alternative 400 V motor, robust and reliable, stable gear pump Manometer for flow- and element control Pressure switch for selection setting in unattended operation 24/7 – unattended operation Pumping without filtration Flow regulation for high viscosity oils Element lifter for simple and fast element exchange

Request for a quote

KASPAR SCHULZ BRAUEREIMASCHINENFABRIK & APPARATEBAUANSTALT GMBH

Germany

Make SCHULZ your choice for both building and brewing: Every detail of your brewery project is in good hands with our outstanding team. Whether it’s the building design, part manufacturing, or installation, every detail is ironed out according to the customer’s wishes. In our mind, success lies not only in state-of-the-art brewing technology, but in the ongoing dialogue with the client as well. Dimensioning (layout) and delivery of: Malt milling equipment, brewhouses, energy-saving systems (e.g. vapor condenser, vapor compressor, and Gentle-Boil System SchoKo 2.0), water tanks, wort cooling treatment, lactic acid plants, fermentation and storage tanks, yeast storage cellar incl. purely cultivated yeast, CIP systems, filtration, pressure tanks, keg and bottle filling equipment (in cooperation with reputable suppliers), consumption and waste figures, refrigeration systems, compressed air systems, power and heating supply.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

To conform to market requirements, widely differing machines for painting/coating mouldings, window parts and other profile components were developed. The type and number of guns depends both on the paint system and on the quality envisaged. Air, Airmix or Airless spraying systems can be used for this purpose. The individual machine types can be configured with all conveyor systems of our portfolio and combined with the respective drying systems. The difference between the VEN SPRAY MOULD (LT) and (LW) variants is their type of extraction. LT stands for dry extraction, LW for water-backed extraction. VEN SPRAY MOULD COOLAC is exclusively designed for processing water-based paints. The overspray is constantly collected and condensed in chilled collector systems. The condensation of the controlled air humidity keeps the collector devices and chilled conveyor systems permanently wet. This reliably prevents paint particles from drying during operation. The strip painting plants can be supplemented by further Venjakob plant technologies specifically tailored to the process such as brush sanding/denibbing machines, dryers or conveying equipment.

Request for a quote

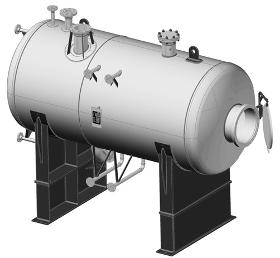

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Pressure vessel design Volume according to customer requirements OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement ACCESSORIES on demand level indicators condensate drainage systems sump heating GENERAL & FUNCTION The condensate tank type VKAB collects liquids and condensates, which are generated during the cleaning of gas in liquid separators. The condensates are discharged from the separators into the tank and serve for pressureless intermediate storage. The design is carried out as a steel welded construction in a horizontal design and is designed as a pressure vessel with 3 bar. QUALITY MANAGEMENT DIN EN ISO 9001 certified

Request for a quote

KRONSEDER TROCKENTECHNIK GMBH & CO. KG

Germany

KET energy-efficient dryer with heat pump and buffer 20 m³ - 60 m³ stacking space The KET has an energy-saving heating system. The heat pump is the heart of the plant, it heats and cools. The cooling system condenses the moisture escaping from the wood and uses the heat this produced to heat the system. The system is supplemented by a buffer which makes use of the stored heat to heat up the vacuum dryer. Increases energy efficiency by 25 % Surplus energy from drying is used for heating The heat pump is used in the heating up phase for heating and demoisturizing No water connection required No heating connection required Areas of application: Sawmills, lumber and hardwood trade, wood industry

Request for a quote

ARMACELL GMBH

Germany

THE STEP AHEAD PIPE SUPPORT FOR FAST INSTALLATION AND CONDENSATION CONTROL WITH AF/ARMAFLEX Armafix pipe supports are recommended for use where thermal bridging may occur. This is particularly important on refrigeration and chilled water pipes where there is a possibility of condensation taking place, between the pipe and its fixing. In heating installations the use of pipe supports will generally improve energy conservation. Insulating the entire pipework system – inclusive pipe hangers - ensures effective de-coupling from supporting and structural elements as well as other service installations. This prevents acoustic bridging, often responsible for the majority of pipework noise within the building. The flexible insulation system for reliable condensation control, trusted for 40 years

ARMACELL GMBH

Germany

THE FLEXIBLE INSULATION SYSTEM FOR RELIABLE CONDENSATION CONTROL, TRUSTED SINCE 40 YEARS AF/Armaflex is the professional flexible insulation for reliable continuous condensation control. Its unique microcellstructure makes the product easy to install. The optimal combination of a very low thermal conductivity and extremely high resistance to water vapour transmission prevents long-term energy losses and water vapour ingress and reduces the risk of under insulation corrosion. The built-in Microban ® antimicrobial protection and the excellent fire performance make the product especially suitable for use in public buildings and process industries. The complete AF/Armaflex system family offers a secure and complete solution for all areas of application. The step ahead pipe support for fast installation and condensation control with AF/Armaflex

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

For over half a century, NASH systems have been the products of choice for air removal systems in steam cycle power plants throughout the world. By reducing the energy loss due to air leakage into the condenser, our vacuum systems save millions of dollars worth of energy every day.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Condensate systems - Import exportNumber of results

17 ProductsCountries

Company type