- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- compressed gases

Results for

Compressed gases - Import export

RIEGLER & CO.KG

Germany

Compressed gases are removed from gas cylinders using RIEGLER flange pressure controllers, which are used during welding, cutting or other related processes. We offer flange pressure controllers according to DIN EN ISO 2503 for flammable and non-flammable gases up to 200 bar and up to 300 bar. All flange pressure controllers are each equipped with a pressure gauge for the display of the cylinder contents and the working pressure. In addition you can also get flange pressure controllers with a flowmeter. Our flange pressure controllers can be used for oxygen, compressed air, nitrogen, carbon dioxide, argon, acetylene, hydrogen, methane, illuminating gas and natural gas.

Request for a quote

RIEGLER & CO.KG

Germany

Compressed gases are removed from gas cylinders using RIEGLER flange pressure controllers, which are used during welding, cutting or other related processes. We offer flange pressure controllers according to DIN EN ISO 2503 for flammable and non-flammable gases up to 200 bar and up to 300 bar. All flange pressure controllers are each equipped with a pressure gauge for the display of the cylinder contents and the working pressure. In addition you can also get flange pressure controllers with a flowmeter. Our flange pressure controllers can be used for oxygen, compressed air, nitrogen, carbon dioxide, argon, acetylene, hydrogen, methane, illuminating gas and natural gas.

Request for a quote

APROVIS

Germany

What you can expect from an APROVIS process gas heat exchanger: - Suitable for low and high temperature ranges - Operating pressures up to 160 bar - Compact design for use in confined spaces - Suitable for a wide range of gases - Implementation of customised solutions

Request for a quote

OHMEX INDUSTRIELLE ELEKTROWÄRME GMBH

Germany

Explosionproof/flameproof gas preheater EEx d -ATEX und IECEx zertifiziert In general a cooling down takes place at expansion of gases whilst a heating takes place at compression. Typical gases are carbon monoxide, natural gas and air. The temperature change, which occurs at expansion of gas or gas mixture from a high to low pressure i.e. after a gas pressure control is called Joule-Thomson effect. In order to prevent the effects of Joule-Thomson as icing or condensate separation, the gas will be heated up before expansion. The gas pre heaters are suitable for all kind of gaseous media (i.e. air, natural gas, technical gases, fuel gas) and low flow process applications, suitable for pressures up to 300 bar. The “Cast electric heaters” type flameproof electrical gas pre heaters are certified for use in zone 1 or 2 hazardous area, custom built to meet client specification. The gas pre heater consists of a process tube coil and an electrical heating bundle, casted in aluminium. The process gas flows through the tube coil and is heated by the aluminium block that provides the heat transfer. This indirect electric heating gives an accurate control of the process and eliminates pressure vessel design and associated costs.

Request for a quote

PFEIFFER VACUUM GMBH

Germany

turbomolecular vacuum pump, hybrid bearing, ceramic ball bearingCompact yet powerful turbopumps with pumping speeds of up to 67 l/s for N2 Product description * - Compact design for minimum footprint * - High pumping speed and maximum compression for all gases * - Integrated drive electronics, suitable for industrial environments - Protection class IP54 * - Semi S2 and UL/CSA certification * - Ideal for all standard applications * - Patented laser balancing™ technology * - Maximum reliability through monitoring of operating data

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BDSENSORS GMBH

Germany

The DMD 341 is a differential pressure transmitter for non-aggressive gases and compressed air. Because of its compact and robust aluminium housing it is suited for machine and plant engineering. Basic element is a piezoresistive stainless steel silicon sensor, which features high accuracy and excellent long term stability. In combination with our display and switching unit ASM 430 the user has a 4-digit LED-display for representing the differential pressure as well as up to 2 freely configurable contacts. Features: — differential pressure 0 ... 6 mbar up to 0 ... 1000 mbar — accuracy: 0.35% / 1% / 2% FSO — piezoresistive silicon sensor — compact and robust aluminium housing — suited for non-aggressive gases and compressed air — current and voltage output signals in 2- and 3-wire systems Optional Features: — display and switching module with up to 2 contacts — customer specific versions

Request for a quote

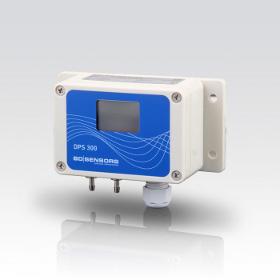

BDSENSORS GMBH

Germany

The pressure transmitter DPS 300 was developed for the differential pressure measuring for dry, non aggressive gases and compressed air and can be used for several HVAC applications. The DPS 300 is a multi range transmitter with up to three adjustable ranges. The device is equipped with a two-line LC display optionally and can simply parameterised. Values, status of the contact and the unit are shown on the display. Features: — differential pressure 0 ... 1.6 mbar up to 0 ... 1.000 mbar — accuracy: 0.5 % FSO BFSL — current and voltage output signals in 2- and 3-wire systems — adjustable ranges — adjustable damping Optional Features: — LC-display, two-line — automatic zero adjustment — contacts (only in combination with display) — square root extraction (only in combination with display)

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTISONIC 7300 is a universal 2-path ultrasonic gas flowmeter for process and utility gas measurements in oil and gas refineries or the chemical or petrochemical industries. It is also suitable for non-custody transfer natural gas applications or applications with (compressed) air, mixed or flue gases (up to +180°C / +356°F). Using the transit time differential measuring principle, the OPTISONIC 7300 delivers high performance over a wide flow range (up to DN600 / 24", turndown ratio: 100:1). The measured volume flow can always be calculated to standard conditions using the input of temperature and pressure sensors, which can be directly connected to the device. Following the initial calibration, the device provides accurate measuring results (±1% error of measured value). The OPTISONIC 7300 does not have the limitations associated with turbine or other traditional gas flowmeters like periodical recalibrations, maintenance, pressure loss and a limited flow range.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Application specific ring sets Improved properties are: Extrusion resistance, if high pressures have to be sealed and/or bigger gaps than the normally recommended max of 25 of the packing size are found. Wiper function, if any micro scaling is found on the stem and at reciprocating movement with control valves Blow out safety, when sealing high compressed gases and fumes Pliability, with low gland forces as well good reset and adaptability for example in applications with temperature cycles. Ring Set 3335 For Control Valves up to 400 °C. Ring Set 6655 For Control Valves and staem applications up to 600 °C steam. All rings are delivered as standard in skive cut. Ring Set 6660 For Valves up to 650 °C steam. This ringset offers minimal volumeloss. The rings in the sealing zone are split as standard in 2 halves or as option delivered with a skive cut. Top and bottom ring are delivered with skive cut. Soot Blower Ring Set For soot blower applications with steam temperature up to...

Request for a quote

EISELE GMBH

Germany

- One interface for compressed air, gases, fluids, vacuum, electrical and electronic signals - Maximum modularity due to freely configurable connections - Integrated coding in the housings prevents incorrect connections - Easy, tool-free mounting and dismounting - Locking lever reduces the force needed for assembly - Machine set-up times are reduced - Fits to Eisele adaptive inserts - Coupling and slotted nut material: Chemical nickel-plated aluminum - Lever materials: anodized aluminum / 1.4301 (304) stainless steel - Other materials: 1.4404 (316L) stainless steel / A2 / POM - Knurled screw with retaining cable

Request for a quote

EISELE GMBH

Germany

- One interface for compressed air, gases, liquids, electrical and electronic signals - Fits to Eisele Adaptive insets - Can be assembled as bulkhead - Material Al nickel-plated or stainless steel - Temperature range -20 to +120 °C - Working pressure range -0,8 to 0 bar or 0 to 24 - Up to max. 14 connections

Request for a quote

BLUESENS GAS SENSOR GMBH

Germany

The robust BCP-CH4 methane sensor is based on infrared gas measurement techique and is available in 2 different wavelengths. Minimum flow is not needed and it can be integrated directly into the gas pipe. A gas cooling is no longer required. Monthly adjustment can be done with fresh air. The sensor is longterm stable and IP65 accredited. The production of methane in biogas plants (methane digester) can be monitored by the BCP-CH4 sensor which helps to optimize the process control. By using BCP-CH4 in block heat and power plants the actual efficiency can be determined.

Request for a quoteResults for

Compressed gases - Import exportNumber of results

13 ProductsCountries

Company type