- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coil winding

Results for

Coil winding - Import export

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Fast and accurate measurements of the smallest resistance values are possible with the milliohmmeter RESISTOMAT® model 2316. Due to the rugged aluminium injection moulding desktop housing with membrane keypad it is suitable for use in laboratory and industrial environment likewise. Wires and coils can be measured with temperature compensation. The temperature of the sample is measured with a Pt100 or pyrometer and the resistance is then corrected to the equivalent at e.g. 20 °C (adjustable) in the instrument. The application range is very wide such as the measurement of: — transformer motor coil windings — coils of all kind — cables and wires on the drum or as meter samples — switch and relay contacts — heating elements — fuses — connections and transitions at power rails and many more Specific characteristics: — Autorange — Temperature compensation for all materials — Thermal e.m.f. compensation — Input voltage protection up to effectively 400 V rms

Request for a quote

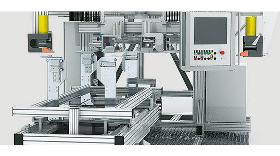

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Coil winding - Import exportNumber of results

4 ProductsCountries

Company type