- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coil material

Results for

Coil material - Import export

GSW SCHWABE AG

Germany

Special Reels are a longtime part of the GSW lineup Our Horizontal Reels (also called “Pallet Decoilers”) for instance, are helping to unwind lying coiled materials. They are best suited for thin strip which often is loaded together with the carrier pallet. GSW Tilting Reels make sense where normal coil loading is difficult or the materials don’t allow that process. Instead, the coil is loaded horizontally and uncoiled vertically afterwards. Paper Winders help to safely process paper interleaf or film coatings innovative expansion and clamping units help for quick and simple handling. Performance Data up to 3t coil weight and max approx. 2mm thickness max crosssection 300 x 2mm max winding or payoff speeds approx. 20 – 100m/min

Request for a quote

SPIROL

Germany

You can rely on SPIROL to be a design partner that helps solve unique problems. Because we supply many customers with similar products in similar industries, we are able to meet most needs with our standard products at no additional cost. When the solution falls outside the normal requirements, we have the expertise and engineering personnel to solve those problems. By working with SPIROL in the design stage of your project, we will develop a solution that lowers your overall product cost, improves product quality, increases the robustness of your manufacturing process, and gets you to market faster. There are a number of common special Coiled Spring Pins that SPIROL has designed over the years to meet specific performance requirements. This includes making Coiled Pins from special materials such as 316 stainless steel, beryllium copper, and Inconel, or designing Coiled Pins to meet unique application requirements resulting in custom diameters, custom lengths, special features, etc.

Request for a quote

SPIROL

Germany

The Series 500 Extra Light Duty Coiled Pins were specifically designed for use in soft or fragile materials. The 1½ coil formation ensures that the radial force exerted against the hole wall does not exceed the strength of the hole material to prevent deformation. These pins are also an economical solution where pin strength is not a major design consideration. Typical applications for Series 500 Extra Light Duty Pins include: hinge pins in plastic or ceramic assemblies, alignment pins, and fastening applications where the hole is close to an edge of an assembly component.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

LESJÖFORS INDUSTRIAL SPRINGS & PRESSINGS GMBH

Germany

Volute Springs are used as compression springs and made from flat material coiled to a volute. The coils of the material overlap each other and are guided radially by each other during compression, thus giving the spring a stability against buckling that cannot be achieved with conventional compression springs.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

X2000NC for producing door strikers Modular tool set on an X2000NC line for the production of door strikers from 8 mm wire. Striker sprinter tool, 3 stations, 2 m back wall, feeding of coil material via NC roller infeed, cycle output: approx. 60 pcs/min, ready-to-use, weight approx. 10 t Door striker production With these specifications, our X2000NC is the world’s fastest system for the production of door strikers for the automotive industry. With tool changes, different striker shapes can be achieved, as well as processing details such as upsetting or tapering at wire ends. Our one-of-a-kind production model enables cycle times of more than 60 pcs/minute. For this reason, we’d prefer not to share the technical details of our strategy online. If you’re interested, please arrange a meeting with a member of our field sales team. Incidentally, we also build assembly systems for coupling door strikers to striker plates.

Request for a quote

GSW SCHWABE AG

Germany

Paper Unwinder with a mechanical drag brake and conical clamping system, available in different sizes and versions for all types of coil reels and for all material widths Paper Recoiler, for all types of coil reels and for all material widths, with air motor or with electromotor

Request for a quote

GSW SCHWABE AG

Germany

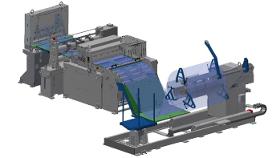

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

GSW SCHWABE AG

Germany

For onesided loading, GSW has five product series – and can thus answer basically any need in coil size, weight or width LHD, the light Coil Reel for up to 1 ton coil weight, with bevel gear expansion; LMHD, the light Coil Reel of our mid series for up to 1,5 ton, with lever arm expansion; MHD, the medium Coil Reel for up to 6 ton, with mechanical or hydraulic lever arm or key wedge expansion; SHD, the heavy Coil Reel for up to 25 ton, with hydraulic key edge expansion and SHZ, the twosided Coil Reel to handle heaviest and very wide coils. Performance data up to 30t coil weight and max 16mm material thickness max crosssection approx. 2000 x 5 mm max pulloff, decoiling or recoiling speed approx. 80 – 150 m/min

Request for a quote

KULLEN-KOTI GMBH

Germany

The STS-spiral coil is the only brush type that can be produced with very small diameters starting at an overall diameter of 17 mm. Offering an enormous choice of dimensions and fill material qualities this brush has almost unlimited applications in light or medium work. The long period of development of this brush type has left its mark and appears in every detail of the brush. The diagram below shows how the STS coil is constructed: the fill material is fixed with a locking wire inside the backing tape. Available backing tapes We manufacture the STS-brush in eight different coil widths (WB) from 2.5 mm to 13.5 mm. As material we use mild steel, stainless steel (1.4301, 1.4571) or brass. STS-spiral coils can be supplied for self installation, as well as a complete roller brush with shaft. Variety The STS-spiral brush offering an enormous choice of fill material, fill arrangements and fill densities. Depending on the fill material and dimension we can also increase the density by...

Request for a quote

GSW SCHWABE AG

Germany

high accuracy for feed repeat of +/ 0,05 mm high clamping force to serve even large material crosssections serving a wide variety of materials, such as coil, band, bar or profile stocks or even wires, cardboards, papers and fabrics operation in push or pull mode or combined in pushpull mode special air cylinder design for reduced air consumption feed length adjustment via finethreaded spindle

Request for a quote

SPIROL

Germany

The Coiled Spring Pin was invented by SPIROL in 1948. SPIROL offers Coiled Pins in three duties, light, standard and heavy, to provide a variety of combinations of strength, flexibility and diameters to accommodate different host materials and applications. Standard duty (sometimes called "medium" duty) Coiled Spring Pins are generally recommended for use in nonferrous and mild steel assemblies and provide the optimum combination of strength and flexibility in these materials. Standard duty Coiled Pins are also preferred in hardened components when there is enough space to accommodate the larger diameter to withstand the applied force because of their ability to absorb shock and vibration. SPIROL's standard duty Coiled Spring Pins are offered in both metric (conforms to ISO 8750 and ASME B18.8.3M) and inch (conforms to ASME B18.8.2) sizes.

Request for a quote

GSW SCHWABE AG

Germany

material sparing uptake and deposit of coils coil uptake in standing and lying position handover to vertical or horizontal coil reel It is possible to singularize coil stacks as well as to temporarily store them at the production machine in upright or horizontal position. suitable for material widths of up to 500 mm the automatic positioning of the tilt nose guarantees a straightford uptake of the coil. The edge of the material is also treated with more care. The largescale, rounded coil support in the tilt nose prevents the material at the coil eye to be damaged. secure handling with inbuild guide handle, tilt nose automatically slides below the coil coil can be lifted jerkfree because of its unrolling coil nib it is not possible for the coil to slip off during transportation

Request for a quote

SPANSET SECUTEX GMBH

Germany

Again and again, coils with larger internal diameters than expected have to be processed on coilers. Here the secutex coiler sheath offers a simple and flexible solution to the problem. Enlargement of the internal diameter The handy secutex coiler sheath is simply pushed onto the coil mandrel and enlarges the radius to the required size. The timeconsuming assembly of subcomponents is no longer necessary. Prevention of dents Thanks to the high friction of the secutex material, the coil cannot slip and, in some cases, the contact pressure can be significantly reduced. The typical impressions in the initial winding layers are prevented and material wastage is significantly reduced. The secutex material is extremely wearresistant and, unlike standard rubber, is also oilresistant. The insertion tip helps thread the coils.

Request for a quote

GSW SCHWABE AG

Germany

GSW Roll Feeds Precise and fast positioning with lasting performance. Built with the attributes of parallel adjustment of the top roll, highprecision roll guiding and mechanical stroke limitation for fastest cycles. In combination with most modern motion control systems our Roll Feeds feature a highly reliable production support with dynamic feeding performance of max 30 m/s² acceleration. For smaller crosssections we offer the HSseries Roll Feed model This dynamic and costeffective solution makes the upgrade from gripper feeds to the much more flexible roll feed technology affordable. from coil up to 2000 mm material width and up to 8 mm thickness max crosssection approx. 2000 x 5 mm Vmax approx. 80 200 m/min max cycles with pilot release approx. 100 220 SPM from plate or bar up to 20 mm material thickness

Request for a quote

GSW SCHWABE AG

Germany

Coil Reels with loading capacity on both ends more productivity and shorter setup. While the one arbor is working, the other one takes a new coil. With four product series GSW basically covers any need in coil size, weight or width LH, the light DoubleEnded Coil Reel for up to 2 x 1 ton coil weight, with bevel gear expansion and manual rotation; LMHD, the light DoubleEnded Coil Reel of our mid series for up to 2 x 1,5 ton, with lever arm expansion and manual rotation; MHD, the medium DoubleEnded Coil Reel for up to 2 x 6 ton, with mechanical or hydraulic lever arm or key wedge expansion and manual or motorized rotation; SHD, the heavy DoubleEnded Coil Reel for up to 2 x 15 ton, with hydraulic key wedge expansion and motorized rotation. up to 2 x 15t coil weight and max 10mm material thickness max crosssection approx. 2000 x 5 mm max pulloff, decoiling or recoiling speed approx. 50 – 100 m/min

Request for a quote

KULLEN-KOTI GMBH

Germany

A very interesting aspect of our STS-spiral coils is the type with inverted fill material that is used, for instance, for polishing, descaling or removal of corrosion off rods or wires in a continuous operation. With an outside diameter of only 20 mm it is possible to reach an inner diameter of zero. Offering an enormous choice of dimensions and fill material qualities this brush has almost unlimited applications. The pioneering of this brush type has left its mark and shows in every detail of this brush. The diagram below shows how the STS coil is constructed: the fill material is fixed with a locking wire inside the backing tape. Available backing tapes We manufacture our STS-spiral brushes in eight different coil widths (WB) from 2,5 - 13,5 mm. As material we use mild steel, stainless steel (1.4301 or 1.4571) or brass. Variety The STS-spiral coil offers an enormous choice of dimensions in fill material, fill configuration, fill density.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GUTEKUNST FEDERN

Germany

Technical Data Mat EN 10270-3-1.4310 - type of material Wri Left - coiling direction d 0.4 mm Wire diameter Di 1.6 mm inner coil diameter Ditol 0.08 mm (+/-) tolerance of inner coil diameter Dd mm diameter of mandrel Ddmin 1 mm Min. possible mandrel diameter Ddmax 1.3 mm maximum possible mandrel diameter Lk0 1.2 mm length of spring body Ls 20 mm leg length LsH mm leg length of the lever leg LsR mm leg length of the recumbent leg alpha 0 degree leg position when relaxed alpha1 degree prestressed rotational angle alphah degree working rotational angle alphan 23.35 degree maximum

Request for a quote

DIMET GMBH

Germany

USED FOR HANDLING OF large diameter pipes. Specially designed for large diameter pipe lifting / copper coil as an option / hot material handling up to 650°C as an option

Request for a quote

DIMET GMBH

Germany

USED FOR HANDLING OF coils / rod and rebar in coils. Specially designed for eye vertical coil lifting / copper coil as an option / hot material handling up to 650°C as an option

Request for a quote

DIMET GMBH

Germany

USED FOR HANDLING OF - bundles of coil, rod, rebar / rod and rebar in bundles. Specially designed for long-length cargo / copper coil as an option / hot material handling up to 650 C° as an option.

Request for a quote

ARMACELL GMBH

Germany

THE PATENTED EASY-TO-INSTALL, PRE-INSULATED PIPING SYSTEM FOR EFFICIENCY IN SOLAR HOT WATER APPLICATIONS Armaflex DuoSolar is a system solution with pre-insulated feed and return pipe for solar hot water applications. Armaflex DuoSolar is used to connect the solar panel with the thermal storage water heater in an easy and professional way. It optimises thermal efficiency of the entire system and increases life time expectancy of the installation. Thanks to the pre-insulation, the patented join split connection system of the feed and return pipe and the integrated sensor cable, Armaflex DuoSolar saves time and lowers assembly costs. Armaflex DuoSolar, presented in continuous coils to reduce waste material, comes with a complete range of accessories to ensure a smooth & secure installation. The flexible expert for increased efficiency in high temperature applications

Results for

Coil material - Import exportNumber of results

23 ProductsCountries

Company type

Category

- Metal straightening machines (7)

- Lifting equipment (3)

- Machine tools, metal shaping - parts and accessories (2)

- Screw cutting - steels and metals (2)

- Bending - steels and metals (1)

- Bending machine tools (1)

- Coil Springs (1)

- Coil winders (1)

- Fasteners, metal (1)

- Forklift trucks (1)

- Import-export - steels and metals (1)

- Sheet metal and strips, tinplate (1)