- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coated wire

Results for

Coated wire - Import export

HAMBURGER DRAHTSEILEREI A. STEPPUHN GMBH

Germany

The processing of granules into coated long products requires high precision with tools and machine settings as well as sound expertise in the specific characteristics of the materials. As an extrusion specialist of steel cables and other long products such as wires, glass-fibre rods, we offer a wide service range: Plastic coating from ca. 0.5 to 24mm, PA, PE, PP, PUR and PVC and more, additives for special requirements, such as the UV and water resistance, circular cross sections and special dimensions and stock colours or your own selection.

Request for a quote

VKF RENZEL GMBH

Germany

The simple metal stand in silver is a combination of an acrylic pocket and a stand with holder. The poster stand is made of powder-coated wire. The acrylic pocket is fastened and individually equipped with advertising or information pages.

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Spring isolators can be used for source and sender vibration isolation. The springs are manufactured of a special spring steel wire and KTL coated. Every spring isolator can be provided with an additional damping cushion of stainless-steel. Elemente with a frequency range between 3-4 Hz can be provided with a viscous damping, too. Spring isolators with a natural frequency range of 3-5 or 4-6 Hz are especially made for higher forces. They can be expanded in size and load-capacity without any difficulty. Spring isolators of RG+ are available for four different natural frequency ranges: Spring isolators with a natural frequency of 3-4 Hz Spring isolators with a natural frequency of 5-6 Hz Spring isolators with a natural frequency of 7-9 Hz Spring isolators with a natural frequency of 3-5 or 4-6 Hz

Request for a quote

DIETZ GMBH

Germany

Customised production to your specifications: We work very closely with you when it comes to producing torsion springs. Torsion springs are produced in accordance with your specifications based on drawings, prototypes or sketches. We manage the development process of the spring until it is ready for serial production. We produce torsion springs with wire diameters of 0.20 to 4.00 mm, with or without torque testing. Wire coatings: Galvanised, ZnAl-plated, Red-coated, Nickel-plated, Polished nickel, Phosphated, Brass-plated,Silver-plated.

Request for a quote

JINTIAN COPPER

Germany

Main products: Self-solderable polyurethane enameled copper wires, polyester enameled copper round / flat wires, polyester enameled copper round / flat wires, nylon composite coated wires, polyester-imide / polyamide-imide copper round / flat wires, etc. Product characteristics: Excellent electrical conductivity, thermal stability, scratch resistance and solvent resistance; good heat dissipation performance, and high magnetic field efficiency Applications: Wind power, rail transit, new energy vehicles, power transmission and transformation equipment, home appliances Production capacity: 82,000 tons Management system: Strictly implemented Manufacturing Execution System (MES) and VDA6.3 German Automotive Industry Quality Standards

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HEINZE & STRENG GMBH

Germany

We supply the following types: Nickel, steel body with nickel coating, copper and brass Service: Re-use worn put tubes by refurbishing running surfaces - regrinding works. We reduce your maintenance costs and you get a first-class product result - sustainable and efficient. ***Special coating for tinned wire available on request.***

Request for a quote

ELKY GESELLSCHAFT FÜR TECHNISCHE ENTWICKLUNGEN MBH

Germany

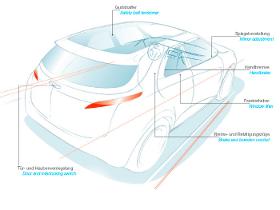

Coated and un-coated manufactured special cables and wires made from a variety of raw materials can be used in various safety, control and attenuator elements in automotive engineering. We stock a wide, extremely varied, range of connection components in a variety of designs, sizes and materials, such as brass, tinplated copper, aluminium and stainless steel. Our products are made to customer specifications, in order to best meet their requirements (including breaking strength, elongation, flexing properties, corrosion resistance, DC resistance, low twist and low tension design, workability). Our manufacturing processes are permanently monitored and secured using appropriate procedures. As standard, we use both galvanised and stainless steel wire in accordance with DIN EN 10 264 with nominal strength of over 3000 Mpa with adequate ductility. We also use the non-corroding materials 1.4301 (AISI 304), 1.4310 (AISI 301) and 1.4401 (AISI 316) as standard.

Request for a quoteResults for

Coated wire - Import exportNumber of results

8 ProductsCountries

Company type