- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coated sleevings

Results for

Coated sleevings - Import export

SPANSET SECUTEX GMBH

Germany

secutex has developed the new “TopDrain” structure surface for lifting wet or oily components. Most of the damages at sharp or rough edges are caused by the movement of the load across the sling. In the case of loads with a “sharp edge” or with a very rough surface, a protective sleeve or fixed coating must be used to protect the textile lifting sling. If the load moves sideways, a cutting movement on the edge is the result. Similar to a knife blade, the edge can cut through the fibers of the textile sling. The new “TopDrain” surface drainage provides good adhesion of the protective sleeves and the coated lifting slings even on wet and oily materials. The liquid can drain off into the surface hollows and the load lies securely in the lifting sling. The “TopDrain” structure works like a drainage and ensures the frictional connection of the secutex coating to the load.

Request for a quote![Protective Sleeve, Single-sided [sf-1]](/filestore/vig280/opt/product/8e/6/secumove_f20eb33a.jpg)

SPANSET SECUTEX GMBH

Germany

The secutex protective sleeve is optimally coordinated from a technical standpoint for the spanset lashing belt programme or the spanset round slings. The contact side is coated with secutex. It is extremely resistant and minimizes the buildup of wrinkles in the textile. The secutex protective sleeve with singlesided coating can be easily pushed over lifting equipment and protects against damage caused by “sharp edges” and the rough edges of the lifting equipment and the load at the same time.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The protection against „sharp edges“ Alongside other factors such as temperature, chemical environment and mechanical loads, the „sharp edge“ remains one of the main causes of damage to the lifting accessory itself and frequent cause of accidents. Most damage on sharp or rough edges is the result of load movement perpendicular to the load lifting accessory. If the edge is „sharp“ it can, in a worstcase scenario, cut through the lifting accessory. If the load moves laterally, a cutting movement takes place at the edge. Much like the blade of a knife, the edge can cut through the fibres of the textile lifting accessory. For loads with a „sharp edge“ or with a rough surface, a protective sleeve or fixed coating is recommended to protect the textile lifting strap.

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

KB RollerTech processes seamless metal belts (stainless steel and nickel). Compared to coated plastic belts, metal belts offer the following advantages: very high thermal conductivity very high physical stability Today, KB RollerTech processes metal belts with the following properties: Properties Nickel belts Stainless steel belts Length < 350 mm < 400 mm Diameter 15 - 50 mm 10 - 100 mm Wall thickness 30 - 500 µm 35 - 100 µm Geometry straight straight and concave Remarks 100 mm diameter only possible with seam Concerning the coatings the following combinations are possible: Nickel belts Stainless steel belts PFA sleeves PFA spray coatings or PFA sleeves Silicone and PFA sleeves Silione and PFA spray coatings or PFA sleeve

Request for a quote

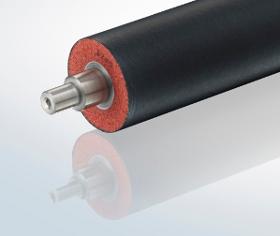

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: homogenous and fine-pored cell structure tight tolerances of silicone foam density defined concave or convex surface shape non-stick top coatings (e.g. PFA sleeves) minimal odor through reduction of volatiles (VOC)

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine technology developed for coating round steel tubes with a temporary corrosion protection convinces with its high performance. The surface quality of the solvent free coating with 100 % UV lacquer, the fast curing time of ≤ 1 second as well as an overspray recovery rate of more than 95 % are impressive features which, by their very nature, offer high economic efficiency. Additional modules individually perform either the cleaning work, dust removal or marking of tubes. This machine technology ensures perfect transport of the tubes without damage to the lacquer coat, while flexibly taking tube properties into account, such as sleeves or caps, diameters from 20-200 or from 200 to 500 mm, required throughfeed speeds of 30 - 100 m/min as well as surface temperatures from +1°C to +40°C. Whether operated as an individual machine or integrated in an adjustment line, the output parameters are characterised by minimum space requirement and low operating and maintenance costs. An alkaline cleaning station that adjusts to the individual degree of soiling of the tube surface to ensure optimum results can be optionally installed together with a drying unit upstream of the pipe coating line. Venjakob offers individual system solutions for coating tube sleeves. This includes the application of a base coat and coloured rings, as well as marking. Customised solutions for tube marking are available as an option.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Coated sleevings - Import exportNumber of results

6 ProductsCompany type

Category