- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cnc processing

Results for

Cnc processing - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Most modern equipped, we meet your demands on highest level! For the mechanical processing, we use modern manufacturing technologies which ensure tailor-made optimized solution on a constantly high quality level. Whether individual parts or small and medium-scale productions, whether small components or XXL parts, we remain at your service. For the customer's data transfer, our modern 2D & 3D CAD systems are available. ■ CNC turning: up to 3000 mm / Ø420 mm (118"/Ø16") ■ CNC milling: up to 7000/2500/1500 mm (275"/98"/59"), part weight up to 10 T (2204 lbs) ■ 5-axis treatment up to Ø 1000 mm (39"), part weight up to 1,2 T (2645 lbs)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4-spindle solution with HSK-A100 on MFZ Machining of the free cut with 4 spindles possible OP 10 and OP 20 are processed in one machine Unit times less than 50s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with a 4-part clamping device Editing the OP 20 after the turning process Piece time less than 90s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

QUICK CHECK GUN DRILL Eight basic cycles, based on experience, are included in the scope of delivery of the machine and guarantee professional processing of the workpiece. Specific groups for cross drilling cycles are available as an option. This makes workshop programming and programming of crossing holes easier by adapting the feed when hitting the cross hole. This increases the tool life significantly.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

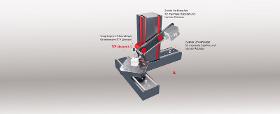

STABILITY AND HIGHEST PRECISION COME BY APPROXIMATE. THE PERFECTLY THOUGHTFUL AXIS CONCEPT IN THE POWER TOWER DESIGN ALLOWS MINIMAL TCP DISTANCE AND MAXIMUM MACHINE STIFFNESS. The POWER TOWER DESIGN impresses with its compact design and extreme rigidity. All components in the force flow are statically and dynamically optimized down to the last detail, thus ensuring perfect work results. The clear separation of all linear axes guarantees long-term dimensional accuracy of all axis drives and sustainably prevents tolerances from overlapping and thereby increasing. Thanks to the large footprint of the Y-tower and the unique DOUBLE BALL SCREW DRIVE, we always achieve optimal support for the drill beam in the TFZ and at the same time an extremely short distance between the swivel bearing and the tool center point (TCP distance), for maximum rigidity with large transverse forces.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

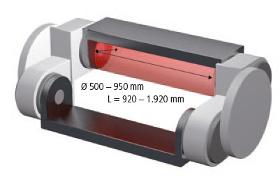

THE MULTI-SPINDLE SHAFT DRILLING MACHINES OF THE TBM roto series ARE DESIGNED FOR PERMANENT PRODUCTION USE. THEY ARE PARTICULARLY DURABLE, EXTREMELY ROBUST AND GUARANTEE THE HIGHEST PRECISION: 24/7/365! TBM roto – shaft drilling machine for production For machining rotationally symmetrical workpieces such as gear shafts, camshafts, steering rods, common rails, standard parts... Customer-specific solutions, automation, handling, workpiece clamping, workpiece cleaning… Long-lasting machines for parts with the highest precision Additional units, features or modules available Optimized accessibility to all components for maintenance and service

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2008 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2008 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm Spindle distance 450mm Chip conveyor Knoll (scratch belt conveyor in positioning variant across the machine) High-quality Knoll KSS system with fine filtration Flush gun Complete enclosure Tool storage (2 x 50 tools) Operating voltage 400V 3N ~ Control voltage 24V DC Connection value machine approx. 72 KVA Compressed air connection 6 bar

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4 SIZES AND LOTS OF POSSIBILITIES! THE SFZ SERIES ESPECIALLY SCORES WITH STRONG PERFORMANCE. Starting from the four basic models of the SFZ series; We offer modular equipment variants, depending on performance requirements. Completely in the spirit of FIT 2 TASK. In order to guarantee individual performance, the SFZ machines are equipped with the latest generation of Heidenhain iTNC640 controls as standard. SIEMENS 840D SL is optionally available as an alternative, depending on your requirements.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

PENDULUM CHANGER – GOOD FROM EXPERIENCE. The W-axis principle, established by SAMAG since 1995, enables workpiece loading to be carried out parallel to production times. The workpiece carrier table is moved in the swivel drive from 0 – 180°. This means that the next loading and unloading of workpieces can take place during processing. Efficient and useful also for robot-assisted loading.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

The frame construction concept offers reliable stability thanks to its closed design. The power transmission through the axis movements in the working area does not cause any deformation of the frame. This extremely stable solution is a prerequisite for the high-precision machining of your workpieces and guarantees consistently high process quality. The new generation of the MFZ is also built on the solid machine bed with Hydropol ® filling. The specially developed composite material improves the stability of machine tool beds. Hydropol ® makes a further step possible in terms of the interaction between energy efficiency and high productivity.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

SIMPLY ROTATE THE 3D UNIT BY 90° AND THE MASS THAT HAS TO BE MOVED IS ONLY HALF AS BIG! ZERO GRAVITY DRIVE – OR TURN WITH MASS. Through the rotation and the resulting reduction of the mass to be moved - by around half - we can use the ZERO GRAVITY DRIVE to achieve an incomparably efficient, dynamic and stable type of spindle movement in all three spatial axes. This new kinematic concept is unique in multi-spindle machining centers and enables maximum efficiency and absolute precision on the one hand and maximum utilization and extreme cost-effectiveness on the other.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

4-spindle solution for pre-processing 2-spindle solution for fine boring with independent X, Y and Z axes Cycle times less than 30s possible

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 3 or 4 spindles OP 10 and OP 20 are processed in one machine Complete processing in 67s

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

2-spindle solution with 4 parts clamping Processing in one setup Machining time less than 82s per workpiece Machining with 4 spindles Tool monitoring for all tools takes place parallel to production time

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

MFZ SERIES – FIT 2 PART – YOUR TASK DEFINES OUR MACHINE. Highest performance and output per square meter, at the same time lower costs and higher productivity – that was the task for our engineers and developers at SAMAG MachineTools. The result: the MFZ series with FIT 2 PART. The conception of the new series leaves nothing to be desired. Technological know-how - for the highest precision with the greatest possible productivity - coupled with passion and innovation, means we create the opportunity to continue adapting the performance of our MFZ machine tools to your workpiece in the future - FIT 2 PART! Whether they have complicated workpiece dimensions or are looking for the optimal quantity solution with minimal machine investmen

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

Machining with 4 spindles OP 10 with 4 part clamping on workpiece carrier unit OP 20 with 4 workpieces on 2 rotary tables (5-axis machining

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is the accessoris used for sensor, after machining, and then process black anodize.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

High polish stainless steel flanges are not just functional components in piping systems; they also offer a visually appealing finish that is smooth and reflective. This high polish, often achieved through a process called electropolishing, provides several benefits: Electropolishing Process. Electropolishing is an electrochemical process that removes a thin layer of material from the stainless steel surface, resulting in a smooth and mirror-like finish. This process can also improve the corrosion resistance of the stainless steel by removing surface imperfections where corrosive agents could potentially take hold. Advantages of High Polish Finish Improved Corrosion Resistance: The smoother surface reduces the number of crevices where corrosion could start, thus enhancing the flange’s longevity. Easy Cleaning: High polish surfaces are easier to clean and sanitize, which is particularly beneficial in industries like food processing and pharmaceuticals.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

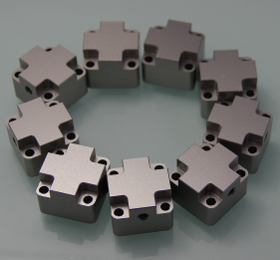

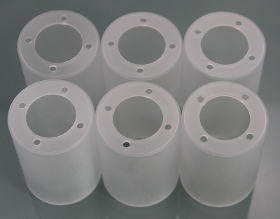

These parts are used for industrial camera accessories。

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material and create the desired shape. A wide variety of materials can be used in CNC turning, including:Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys,ABS...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Golden anodizing specifically refers to creating a layer of golden oxide on the metal surface through the anodizing process. Golden anodized surfaces have a beautiful, metallic gold hue. The color is not only aesthetically pleasing but also provides additional durability and corrosion resistance to the metal.Decorative Purposes: Golden anodizing is often used for decorative purposes, such as architectural elements, jewelry, and consumer electronics. Functional Uses: Beyond aesthetics, it also serves functional purposes, such as preventing galling of threaded components and creating dielectric films for electrolytic capacitors. golden anodizing combines both functionality and aesthetics, making it a popular choice for various applications. Whether you’re looking to enhance the appearance of a product or improve its durability, golden anodizing is a versatile process that delivers impressive results.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

custom printer accessories for machining.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These accessories use for precision machinery parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories are mainly used in wide range of furniture accessories,such as the door insert, and some cabinet kit and so on...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts made by aluminum, which was machining by CNC milling machine,there is no surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories made by aluminum, which used in many fields ,such as industrial, medical equipment and other industries.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This part is use for printer accessories,after CNC Milling,processing black anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Anodized aluminum is a process that enhances the durability and resistance of aluminum by creating a protective oxide layer on its surface. This layer not only prevents corrosion and wear but also allows for custom surface coloration. Here are some key points about blue anodized aluminum: Color Options: Aluminum can accept a wide spectrum of anodized colors, including blue. Other available colors include pink, black, silver, gold, green, orange, red, and purple.Anodization serves multiple purposes: Corrosion Resistance: The protective oxide layer acts as a barrier against corrosion. Aesthetics: Anodized aluminum looks sleek and reflective due to the uniform oxide layer. Scratch Resistance: The tough anodic finish increases scratch resistance. Other Qualities: Anodization also affects wear resistance, heat dissipation, and adhesion. blue anodized aluminum combines aesthetics with functionality, making it a popular choice for various applications.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories mainly used in water sports accessories.

Request for a quoteResults for

Cnc processing - Import exportNumber of results

50 ProductsCountries

Company type

Category

- Mechanical engineering - custom work (15)

- Milling - machine tools (3)

- Bending machine tools (3)

- Automobiles (2)

- Bicycle accessories (2)

- Milling - steels and metals (1)

- Turning - steels and metals (1)

- Steels and metals - machining (1)

- 3D printers (1)

- Agricultural machines and accessories (1)

- Aluminium coatings (1)

- Astronomy - instruments and equipment (1)

- Construction - Machines & Equipment (1)

- Cutting - machine tools (1)

- Filters for cars, lorries and construction machinery (1)

- Fittings, metal (1)

- Fittings, pipe, tube and hose - plastic (1)

- Furniture kits (1)

- Heating and air conditioning - works (1)

- Industrial valves, operating equipment (1)