- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chucks

Results for

Chucks - Import export

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Lower mass The »mini« series really shines with a mass reduced by as much as 30 %, and a chuck diameter that is reduced by 1/3. This means reduced energy consumption and better tool accessibility. Naturally, add on clamping elements can also be used with the TOPlus mini chuck. To maintain the minimal interference contour, the TOPlus mini chuck has its own adaptation devices with a smaller bolt hole circle. Reduced interference contour Thanks to the reduced interference contour, it is easier to choose the tool that you need. Now it can also be shorter and more stable – on the main and sub spindles. Particularly in the case of limited installation space and in series operation, the TOPlus mini chuck is ideal: Lower energy consumption, dynamic spindle acceleration, and shorter cycle times reduce the costs per workpiece. Minimalism that pays off!

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

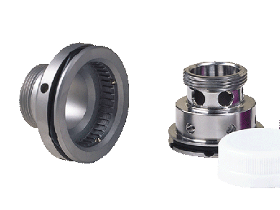

Reaching concentricity 0 using a simple collet chuck and this within one minute: this is Zero-Zero. The specifically designed clamping nut with 6 symmetrically arranged screws at the circumference makes this step possible. The clamping nut is split, so that the inner ring can be minimally shifted. This simple technical finesse allows to eliminate tolerance additions. The machine operator only has to replace the previous clamping nut, which step opens up a new concentricity dimension – and this for a price starting at € 90.00. Zero-Zero is available for DIN 6499 collet chuck holders from ER 16-ER40.

Request for a quote

MIR HAN BAU GMBH.

Germany

BEEF OUTSIDE/INSIDE beef SHIN/SHANK BONE-IN BEEF CHUCK BEEF CLOD beef CHUCK ROLL beef Brisket beef Bone-in brisket Chicken wing root beef Back bone beef chuck bone beef rib eye bone/cube role bone beef Sternum/brisket bone beef shoulder bone beef bone/ nest bone/ knee bone Beef Brisket Fat Beef plate muscle Beef Ligament

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Long-term lubrication of dirt-sensitive sliding points under vibration stresses Particularly suitable for lubricating chucks on tool machines Broad range of uses at stress-loaded parts, also at contact with cooling lubricants Lubrication of control and drive mechanisms Can be used at filling, labelling and packaging machines Advantages and benefits Resistant to water, steam and aqueous cooling lubricants Prevents frictional corrosion reliably Highly effective due to optimum solid lubricant combination Minimal consumption due to formation of highly effective lubricating films For optimum adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply sufficient paste evenly to the functional surfaces with a brush, spatula, etc. The paste will also act as a sealant. Do not use paste instead of grease and mix only with suitable lubricants.

Request for a quote

SPIROL

Germany

SPIROL offers a line of light duty and heavy duty Pin Driving Chucks designed to be used in SPIROL’s Manual Pin Inserters (Model PM, Model PMH or Model PMX). A Pin Driving Chuck may also be used in a drill press or arbor press with an adaptor. All Pin Driving Chucks are designed with spring tension at the tip to hold the pin securely in place prior to and during installation. The exposed end of the pin is then placed into the hole and the tool is advanced to complete the installation. The tools are supplied with a flush, above-flush or below-flush setting, depending on the application requirements.

Request for a quote

ETH MESSTECHNIK GMBH

Germany

No service needed because of contact-less data acquisition Frequency modulation and strain gauge principle cause high accuracy Ordinary power supply High interference rejection because of amplified active signal Quick-release coupling Short form, especially suitable for automatic screwing machines Measurement, adjustment and examination without removing the screwing tool Suitable for permanent use (even with higher speed) Suitable for clockwise and counter-clockwise measurement hexagonal drive very short construction 6 torque range from ± 0 - 2 Nm to ± 0 - 20 Nm rotation angle measurement option

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precision grinding and eroding. The low magnetic field height prevents magnetization of the processing tools. The chipboard is activated via a removable hex shifter. Structure: — Neodymium magnet system, steel body — transverse pole pitch 1.4 + 0.5mm — Holding power 100 N/cm2 — Magnetic field height 5mm — Pole plate wearing limit 6mm Recommendation: High-precision chuck for grinding and eroding

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Super lightweight aluminum body for direct installation of clamping elements. The PMNM UPC pallet is delivered completely ready fitted to fit the Erowa UPC clamping system with original Erowa elements. Optional with handles and/or link Gripper. is used to clamp small and medium-sized workpieces. It works without an external power supply and is activated manually via a changeover lever.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent Magnetic Circular Chuck Type RM, with reinforced ceramic magnet system can be used for clamping bulky and heavy workpieces. The magnetic force is infinitely variable, in the surface incorporated centering grooves facilitate alignment of the workpiece. In the rake face, a center hole can be introduced. Structure: — Ceramic magnet system, Aluminum body, — Max Pole pitch 5+8mm — Holding power 140N/cm² — Magnetic field height 8mm — Pole plate wearing limit 8mm — Switch travel MAG-ENT-MAG 500° Recommendation: Super Strong circular chuck for turning, also for rough parts

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent Magnetic Circular Chuck Type RNF with neodymium magnet system and low height are used for clamping of small and thin workpieces. Structure: — Neodymium magnet system, steel body, — Max Pole pitch 1,5+0,5mm — Holding power 80N/cm² — Magnetic field height 4mm — Pole plate wearing limit 4mm — Switch travel MAG-ENT-MAG 180° Recommendation: Fine pole circular chuck for small parts

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNEO are super strong, compact plates for heavy cutting. Parts from about 30x15x6mm can be stretched with max. achievable holding forces. Good holding forces can be achieved even on rough surfaces. Optional pole blocks can be built on the PMNEO. This allows turning up the workpiece so that all sides are freely accessible, can be drilled on the magnetic clamping plate and leaves more space for accumulating chips around the component. This allows long-running HSC milling-pieces never sink into the resulting chips. The chipboard is activated via a removable hex shifter. The PMNEO magnetic clamping plate, in 48mm height, is prepared to integrate reference elements directly into the magnetic chuck, so that no additional spectrum is required underneath the magnet.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNM are high precision plates for clamping small and thin parts for precision grinding and eroding. The low magnetic field height prevents magnetization of processing tools. The chipboard is activated via a removable hex shifter. PMNM palletising clamping plates are available in 3 versions: Structure: — Neodymium magnet system, steel body, — Transverse pole pitch 1.4+0.5 mm — Holding power 100N/cm² — Magnetic field height about 5 mm — Pole plate wearing limit 6 mm Recommendation: High-precision plate for grinding and eroding

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXL Magnetic Clamping TechnologyThe FXL square pole technology is the result of over 20 years of experience in magnetic clamping technology and combines solutions to the most common customer requirements in the highest quality design. Magnetic poles, fed by Alnico and NDFeB magnets, are anchored in a solid, super-stiff monobloc body by means of a tool steel insert with M8 internal thread. The back of the clamping plate remains flat and can be drilled in at all points - for example, for inserting a zero-point clamping system. For this purpose, the magnet system is coated with highperformance resin in a multi-stage process, which has a high mechanical strength and ensures absolute tightness and perfect electrical insulation. FXL magnetic clamping plates can be controlled with our FXL-C control units or with almost all control units from other leading manufacturers.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Permanent magnetic chucks type PMNEO-X are super strong compact chucks for heavy cutting. Parts from about 30x15x6mm are stretched with max. achievable holding forces. Good holding forces can be achieved even on rough surfaces. The chipboard is activated via a removable hex shifter. Structure: — Double neodymium magnet system, steel body — transverse pole pitch 11+4mm — Holding power 150 N / cm2 — Magnetic field height 10mm — Pole plate wearing limit 6mm Recommendation: Super Strong chuck for milling

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXL magnetic chucks with pole type 70 are used to securely clamp workpieces from approx. 150x150mm with material thickness from approx. 15mm. Poles of size 70x70mm generate a magnetic field that penetrates approx. 18mm into the workpiece, which is why they are particularly suitable for larger workpieces. Very good air gap behavior also allows uneven workpieces to be clamped securely. In addition, pole extensions with a larger stroke can be used on 70 poles for height compensation. The nominal holding force is a super strong 160 N/cm2 = 7.8kN per pole.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXL-R round magnetic chucks in square pole technology are especially suitable for use on the lathe and on rotary tables of machining centers. The frame construction of the FXL plate can be equipped with centering elements at the front on the clamping side as well as at the rear. All FXL magnetic chucks can be operated with FXL-C or FXL-CT control units.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Pole reversal controllers from the FXL-C family reliably control not only our FXL magnetic chucks, but almost all electro-permanent magnet systems on the market. Input voltages of 100-500 VAC / 50-60Hz and matching modulated, pulsed output voltages and pulse powers of up to 24 kVA are unique key data, which are only required under extreme conditions, but provide maximum stability in normal use. FXL-C is available from simple, handy table-top units to control cabinet versions for large-scale applications; stand-alone from manually operated, part-connected with feedback to the machine up to full integration into the machine control for automated applications.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FXL-CT table-top units are built for a maximum of 2 channels without preselection. They can be used to control magnetic chucks up to a total area of approx. 1.2m2. can be controlled. FXL-CT is designed as a table-top unit or to be attached to the machine wall by means of the magnetic feet on the back. The operation is carried out directly on the device.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

The RCP6 rotary chucks consolidate motorized rotation and gripping movement in a single unit. The rotating axis can perform multipoint positioning between 0 and 360° (one rotation). The rotational speed and acceleration/deceleration can also be set to any value. The chuck module is small and lightweight, as a solenoid gripper is used. Furthermore, the battery-less absolute encoder equipped means that home return is not required.

Request for a quote

CL MACHINERY GMBH

Germany

CSI Standard Chucks Features Precision-engineered single piece design More holding teeth (serration) for increased closure application control Shoulder style design for precise closure seating Hardened stainless steel construction Available for all flat and sports cap designs Gripper chuck design available for specialty applications CSI Standard Chucks Benefits High-speed, efficient performance Precise, consistent application Low application defects Long-lasting performance Chuck solutions for all your capping needs Unmatched Technical Support / Application Expertise!

CL MACHINERY GMBH

Germany

Closure Systems International's Flex-Chuck delivers beverage bottling operator a single-chuck solution that maximizes uptime and throughput, improves capping application performance, and reduces the bottler's total cost of operations. Flex-Chuck Features Versatile Design Eliminates Most Chuck Changes Designs for 28mm and 38mm closures Adapts to multiple knurls: 24, 24/120, 60, and 120 Compatible with cold-fill and hot-fill processes Reduces need for design-specific chuck inventory Eliminates chuck changes during package changeovers Applies most closure designs / knurls for a specific bottle finish Interchangeable with existing chuck / headset designs Hardened stainless steel for increased wear resistance Flex Chuck Benefits Improves Capping Application, Reduces Closure Mis-application Patent-pending design automatically adjusts to accommodate closure diameter variations Innovative grip mechanism adapts to all standard knurl patterns Chuck segments flex as closure sidewalls...

CL MACHINERY GMBH

Germany

The VK900 bottle capper headset is Closure Systems International's tried-and-tested standard headset for aluminum roll-on closures. A customizable configuration of two flange and two thread rollers ensures optimum sealing efficiency. The head's slim construction makes it suitable for use even on small-pitch machines. Reliable & Simple Fast and simple control of side pressure using easy-access adjuster nuts Exactly coordinated leverages allow very small side pressure All bearings are fitted with replaceable bushings for easy replacement Two variable thread rollers and two adjustable flange rollers ensure uniform lateral forces, enabling the thread to be rolled out with maximized precision Tracer pin (safety plunger) prevents the roller arms engaging if there is no closure present NO LUBRICATION required. No grease point! Maintenance-free ejector reduces stress, extending the maintenance intervals 100% stainless steel Versatility The centering bell to prevent skewed closures is...

CL MACHINERY GMBH

Germany

The VK138 bottle capper headset is Closure Systems International's tried-and-tested standard headset for aluminum roll-on closures. A customizable configuration of two flange and two thread rollers ensures optimum sealing efficiency. The head's slim construction makes it suitable for use even on small-pitch machines. Reliable & Simple Fast and simple control of side pressure using easy-access adjuster nuts Exactly coordinated leverages allow very small side pressure All bearings are fitted with replaceable bushings for easy replacement Two variable thread rollers and two adjustable flange rollers ensure uniform lateral forces, enabling the thread to be rolled out with maximized precision Tracer pin (safety plunger) prevents the roller arms engaging if there is no closure present Easily maintained with one lubrication point Maintenance-free ejector reduces stress, extending the maintenance intervals 100% stainless steel Versatility The centering bell to prevent skewed closures is.

CL MACHINERY GMBH

Germany

Closure Systems International's HT6 Headset is a non-ratcheting style headset that incorporates the most advanced hysteresis technology. The HT6 headset is specifically designed for unique specialty applications that are very sensitive to torque variations. Improved Application Torque Consistency Unique magnet configuration provides constant static torque Preferred solution for: ✓ Closures without sidewall knurls ✓ Bottles without neck support rings ✓ Closures with induction seals Low Maintenance Cost 6,000 hours of maintenance-free operation No lubrication required during 6,000 hour scheduled maintenance interval Unique hub configuration eliminates need for daily / periodic lubrication Can be retrofitted to existing installations Headset Exchange and general overhauls available Durable Corrosion Resistant Design Enclosed magnetic system made from high grade stainless steel to prevent corrosion Fully washable Unmatched Technical Support / Application Expertise!

CL MACHINERY GMBH

Germany

Lowest Maintenance Cost 6,000 hours of maintenance-free operation (even in aggressive hot-fill bottling environments) Full stainless steel construction to prevent corrosion Lowest rebuild time / simple design NO lubrication required during 6,000 hour scheduled maintenance interval; unique hub configuration eliminates need for daily / periodic lubrication Less downtime for reduced cost High-Speed, Efficient, Consistent Application Industry-leading closure application speed: up to 50 bottles per minute / 3,000 bottles per hour per head Fully calibrated for static torque and head-rise indication; torque range: 8-34 inch lbs. Operational reliability: maintains calibrated settings in extreme conditions Proven, most consistent application torque performance over the widest range of operating spindle speeds Consistent removal torques for reduced consumer complaints Quick change design: torque adjustment, top load, and chucks Visual indicators Optimal magnet geometry Protected seal...

STARRAG GMBH

Germany

The Dörries CONTUMAT VC series, designed as a double column portal system, is ideal for larger swing diameters of 3,500 to 12,000 mm. The VC range combines all of the advantages of the VCE range with the ability to machine large scale components just as effectively. The positive construction properties of the smaller range are taken over here in correspondingly dimensioned main components. The range also provides high levels of flexibility by combining standard modules, providing the customer with a solution tailored to suit their individual needs. The closed portal construction of the double column vertical lathe guarantees high intrinsic rigidity, while the proven cast construction ensures excellent damping and thermostability. Thanks to these characteristics customers obtain a lathe that provides high machining accuracy, with a long service life

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Unequalled rigidity Up to 25 % more clamping force and higher output – with the same clamping cylinder that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. The clamping head rests with full-surface contact in the TOPlus chuck body – even with large workpiece tolerances. Insensitive to dirt In addition this geometry ensures that TOPlus is significantly less sensitive to contamination than previous chuck/clamping head solutions, and with a concentric precision of approx. 0.015 mm [for chuck size 65]! Thus TOPlus is even better suited for raw material, cast and forged parts, as well as fi ne-particle non-ferrous metals such as brass. Therefore, all-round optimized values make the chuck an ideal partner for modern manufacturing strategies and state-of-the-art machine tools. TOPlus – simply revolutionary!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Maximum precision in a mini format The TOPlus premium chuck is ideal for high-precision clamping of delicate and thin-walled parts, as well as solid and massive parts. In combination with premium clamping heads and when clamping against the end-stop, you benefit from incredible run-out accuracy of ≤ 5 μm. That makes the standard TOPlus premium chuck a better and less expensive alternative to hydro-expansion and diaphragm clamping devices. In addition to high precision, the large opening stroke also facilitates automated loading of the machine – even if the robot is somewhat inaccurate. By the way, slight contact with the workpiece during loading has no negative effect on the TOPlus premium. Despite its high precision it remains »robust« and your process remains stable. The most accurate of all HAINBUCH chucks!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Change over from O.D. clamping to jaw clamping or centric clamping in 2 minutes – without clamping device change-over and without having to align ? No problem, with the jaw modules. Because the basic unit, into which the jaw module is inserted, is a HAINBUCH chuck or stationary chuck. If at times the clamping head reaches its limits because it must clamp a larger area, then use one of the jaw modules. The 3-jaw module is best suited for round workpieces, and if you have cubic workpieces, then rely on the 2-jaw module. This means that for a large parts spectrum you are completely flexible and always have the solution that is ideally suited for the respective clamping situation. Both are small, lightweight, and can be quickly changed over – an ingenious solution for small-series production.

Request for a quoteResults for

Chucks - Import exportNumber of results

56 ProductsCountries

Company type

Category

- Machine tools, metal machining - parts and accessories (17)

- Metallurgy - machinery and installations (14)

- Disks, magnetic (12)

- Magnetic equipment (7)

- Beef (1)

- Screw cutting - steels and metals (1)

- Measurement and control instruments (1)

- Milling - machine tools (1)

- Automation - systems and equipment (1)

- Magnets (1)

- Silicones (1)