- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- chemical treatment

Results for

Chemical treatment - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Nitriding treatment is a chemical heat treatment process in which nitrogen atoms penetrate the surface of the workpiece at a certain temperature and in a certain medium. The products treated with nitriding have excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. The general process of nitriding process :1. Pretreatment: clean, remove oil and dry the metal surface to ensure that the surface is clean and free of impurities. 2. Nitriding treatment: The metal is placed in an atmosphere containing nitrogen and treated at high temperatures to form a nitriding layer on the surface of the metal. 3. Post-treatment: Clean and cool the metal surface after nitriding to remove the residual nitride layer and prevent its oxidation. The nitriding process is of great importance for many industrial fields, such as tool manufacturing and automotive parts manufacturing.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

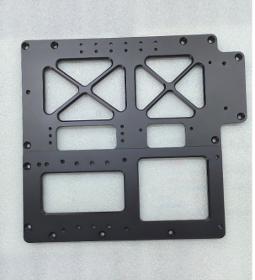

Black oxidation treatment is a commonly used chemical surface treatment method for metal parts, including steel, stainless steel, copper and brass. The principle of this process is to immerse the metal in a heated solution containing oxidized salt, so that the metal surface forms a black oxide film to achieve the purpose of rust and corrosion resistance. This oxide film is usually iron tetraoxide (Fe304), which not only improves the corrosion resistance of the metal, but also gives it a black appearance. This surface treatment is widely used in areas such as precision machining projects, automotive parts, tools and decorations, and the advantages of black oxide include better corrosion protection, reduced light reflection, dimensional stability and aesthetic appeal. In short, the black oxidation treatment is a versatile technology suitable for the improvement and protection of various metal parts.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Plastic blasting abrasives type WIWOX® KS have been specially developed for optimum, chemically neutral surface treatment and all gentle cleaning – especially for plastic and light metal. They are mainly used for paint stripping, roughening, matting, deburring and cleaning. Plastic blasting abrasives produce consistently high quality and do not cause any damage to the work piece to be treated.

Request for a quote

LUTZ PUMPEN GMBH

Germany

High performance, compact dimensions, low weight - everything fits with the Lutz B6. The pump shaft is protected by a shaft guide tube against possible "attack" of the pumped medium. Perfectly suited for pumping and draining of neutral and aggressive liquids with low solids content. * on request also available in special immersion depths of 1000 - 3000 mm * Design according to the single pipe principle * Application examples: For conveying and circulating chemicals and solutions in surface treatment, chemical industry and water treatment, etc. Features & Advantages * Wide range of applications * No risk of leakage at the bottom outlet due to safe product removal * Low wear * Stationary installation possible via flange * Also for small container openings

Request for a quote

AAAGILER GMBH

Germany

Also available as ATEX-suitable, antistatic, electrically conductive GRP (glass-reinforced plastic) gratings, particularly slip-resistant version (R13). With assembly or cutting to size if required. Suitable for roofs, chemical plants, warehouses, airports, water treatment, electricity, port facilities, railways and shipbuilding. Optionally with installation service.

Request for a quote

TEPROSA GMBH

Germany

With the help of the 3D-MID process, plastic parts can be metallized not only over the entire surface, but also selectively. To do this, the plastic part is activated with a special laser at the points that are to be coated (this is referred to as laser activation or laser direct structuring). The additives contained in the plastic directly under the plastic surface are “exposed” by the laser treatment. In a chemical bath, copper particles can then be deposited specifically only on the activated surfaces. Other metals, e.g. nickel, tin or gold, can then be deposited onto the starting layer of copper. In this way, a selectively coated plastic part is obtained. MID technology thereby makes it possible to selectively coat two-dimensional and also three-dimensional plastic parts and use them, for example, as circuit carriers for electronic or mechatronic assemblies. With the LPKF-LDS process

Request for a quoteFAUDI GMBH

Germany

Advantages Micro filtration Area of application Chemical industry and drinking water treatment Flow rate Various filter sizes and the modular design enable any required flow rate. classification number P62 Filter aid - Filtration degree - Medium Methyldiethanolamine (MDEA), drinking water Filter material Activated Carbon

Request for a quote

FUCHS GMBH & CO. KG

Germany

As with all agricultural products, herbs and spices are exposed in the field to many germs conveyed by soil, wind and animals. Over the years, we have developed various technologies which, in a very gentle way, greatly reduce the total germ counts of herbs and spices, while optimally preserving their colour and aroma. LiquidControl Pasteurised, liquid and paste-form herb and spice preparations The LiquidControl (LC) procedure allows the food industry to use herb and spice preparations with a greatly reduced germ count. The gentle pre-heating ensures high quality in the end product. Seasoning intensity and a fresh colour are retained without adding preservatives. Customised LC products are delivered in aseptic containers with an online dosing device. Benefits at a glance: Safe and stable products with germ reduction No added chemicals, no gas treatment or radiation Avoidance of preservatives and high-temperature processing

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the GLP on a drum.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GLP - Peumatic top-entry agitator The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the...

Request for a quote

PURION GMBH

Germany

The integrated plant PURION PooL 40 PVC-U consists of a filtration of sediments and UV based disinfection of pool water. It is applied to disinfect circulation water of pools. The pre filter removes sediment from the pool water. The following UV based disinfection prevents biological activities – especially forming of algae. advantages: plug and play system for immediate operation up to 95% reduction of chemicals compared to chemical treatment of the water considerable cost cutting due to less cost for chemicals suitable for salt water application low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The integrated plant PURION PooL 80 consists of a filtration of sediments and UV based disinfection of pool water. It is applied to disinfect circulation water of pools. The pre filter removes sediment from the pool water. The following UV based disinfection prevents biological activities – especially forming of algae. advantages: plug and play system for immediate operation up to 95% reduction of chemicals compared to chemical treatment of the water considerable cost cutting due to less cost for chemicals low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The integrated plant PURION PooL 80 PVC-U consists of a filtration of sediments and UV based disinfection of pool water. It is applied to disinfect circulation water of pools. The pre filter removes sediment from the pool water. The following UV based disinfection prevents biological activities – especially forming of algae. advantages: plug and play system for immediate operation up to 95% reduction of chemicals compared to chemical treatment of the water considerable cost cutting due to less cost for chemicals suitable for saltwater low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

PURION GMBH

Germany

The integrated plant PURION PooL 40 consists of a filtration of sediments and UV based disinfection of pool water. It is applied to disinfect circulation water of pools. The pre filter removes sediment from the pool water. The following UV based disinfection prevents biological activities – especially forming of algae. advantages: plug and play system for immediate operation up to 95% reduction of chemicals compared to chemical treatment of the water considerable cost cutting due to less cost for chemicals low-maintenance operation low operational costs Please contact us for targeted advice: mail: uv-technology@purion.de phone: +49 3682 479087

Request for a quote

MKV METALL- UND KUNSTSTOFFVERARBEITUNG GMBH

Germany

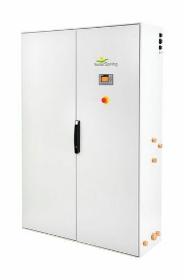

Modern system technology helps ensure more efficient processes. This helps to increase system performance and optimize raw material consumption, while ensuring compliance with production specifications. We develop, build, and install systems for circuit board production worldwide, providing maintenance and replacement parts for most existing systems. Processes we have handled include treatment systems for circuit board plating lines (pattern and panel plating, including in reverse pulse plating technology), as well as systems using dipping basket technology for chemical treatment (including ENIG nickel/gold, ENEPIG nickel/palladium/gold, or immersion tin). We have designed lines ranging from multi-row lines with hoists, including for double goods carriers, and integrating automatic loading and unloading stations with customized frame and chamber solutions.

Request for a quote

SOLARSPRING GMBH MEMBRANE SOLUTIONS

Germany

"Clean water with clean electricity Billions of people still have no access to clean drinking water or lack adequate sanitation. Residents of rural areas are particularly affected. If drinkable water is needed far away from any infrastructure, SolarPurification can help. The system can produce up to 200,000 litres of clean drinking water per day even from heavily polluted surface and ground water. Clean drinking water without chemicals Several treatment stages make it possible that the drinking water is not only clean but also safe. The SolarPurification filters 99.999 % of all bacteria and viruses from the existing water - and this completely without the use of chemicals. This is made possible by a combination of ultrafiltration, activated carbon filtration and UV disinfection. High-quality components, automatic operation with PLC and online monitoring characterize this compact water treatment system. Low maintenance and solar powered

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Passivation is the chemical treatment of surfaces to increase corrosion protection with excellent conductivity. Positive for subsequent painting and powder coating processes, to reduce fingerprint sensitivity and to change the appearance (gloss, color). Maximum measurements 4000 x 1000 x 360 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Chemical treatment - Import exportNumber of results

17 ProductsCountries

Company type

Category

- Water retreatment - equipment and installations (4)

- Water treatment, industrial - systems and equipment (1)

- Pumps (1)

- Aluminium coatings (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Dynamos (1)

- Food Processing (1)

- Grids, gratings and wire mesh (1)

- Laser - cutting and welding machines (1)

- Precious and semiprecious stones and pearls (1)

- Rolling machines (1)

- Water treatment products (1)