- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- case hardening

Results for

Case hardening - Import export

HFP BANDSTAHL GMBH & CO KG

Germany

This material group comprises C-steel with low carbon content, good formability and fineblanking quality. Due to case hardening, the components have low-wear surface layers with high hardness and sufficient toughness in the core. They thus combine numerous properties and application possibilities in a wide variety of industries. To increase the wear resistance, you can also carburize or carbonitrate partial areas. C 10 E, C 15 E /➔ according to DIN EN 10132 - 2 Depending on the customer's requirements, we supply treatment states from soft annealed to high cold solidified.

Request for a quote

KEBA FASTENINGS

Germany

are bolts hot forged from all common materials including stainless, acid resistant and heatproof (inductive hardening, case hardening, quenched and tempered) steel. Diameter range of M 12 - M 80 with lengths reaching up to 800 mm. Tailored manufacturing according to specific standards, drawings and samples.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

Case Hardening Steels & Steels for Quenching and Tempering EN 10083-2 Unalloyed Steel (C 35/C40/C45/C60, C22E – C60 E+U, +N) EN 10083-3 Alloyed Steel (25CrMo4, 34CrMo4, 42CrMo4, 51CrV4, 20MnB5, 30MnB5…) EN 10084 Case Hardening Steel (16MnCr5, 20MnCr5…)

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

We supply both from stocks and productions wide range of round bars , certified acc to. EN 10204 2.2 and/or 3.1 Steels for General Use of EN 10025 (S235/275/355 JR/J0/J2) Steels for Quenching and Tempering acc. EN 10083-2, EN 10083-3 Steels for Case Hardening acc. EN 10084 (C10, C15, 16MnCr5, 20MnCr5, 36CrMn5 (UNI7845) Micro-alloyed Steels (18MnV5, 20MnV6) Free Cutting Steels acc. EN 10087(11SMn30/11SMn37) Other Grades upon request. Structural Steel Carbons Steel Case Hardening Steel Heat Treated Steel Spring Steel Free Cutting Steel Tool Steel Stainless Steel

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

PT screws for thermoplastics: Thread rolling screws for direct screwing into plastics, Thread 30° or 60° KTG screws for thermoplastics: Single-start or double-start thread (high, low) Thread rolling screws are extruded for larger batch sizes and turned for small batch sizes (Turned parts for direct screwing) High tensile and highly stressable connection of thermoplastics with considerably longer life endurance Thread rolling without chips and loss of material Minimum radial tension, large thread coverage Process-reliable due to torsion strength Shorter and slimmer screws are possible. Materials: Steel, case-hardened Quenched and tempered steel 1.5523 tempered to 1000 +200 N/mm², high-grade steel 1.4567, other materials on request Length: 3 – 160 mm (at lengths from 60 mm only partial thread lengths 4 x d are possible) Thread diameter: 1.6 – 10 mm Special dimensions on request Batch sizes: Standard ex-stores Special screws from 30,000 pieces

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

Forget everything you know about miniature gears. Dimensions, weight, precision – the new Power Gear Miniature sets new standards. PowerGear Miniature has a sensationally small installation size, an extremely light-weight aluminium housing, maximum performance and precision as well as many other advantages. The unique design of PowerGear Miniature will open up a vast range of applications in drive technology. miniature gear for maximum precision low backlash and high transmission accuracy case-hardened bevel gear tooth system friction-locked shaft-and-bevel-gear fit energy-efficient through high level of efficiency of 98% extremely light-weight aluminium housing maintenance free through synthetic oil

Request for a quote

FILLTECH GMBH

Germany

Our experience in filling cylinders has enabled us to develop our own pump technology which has proved its worth in a number of fields in addition to filling cylinders. Pump aggregate NP 10/15 Performance Min./Max.: 150-300 kg/h 0.6-1.2 gal/min Power cons.: 1,5 kW Motor: 3x400 V, 50/60 Hz Drive: V-Belt Dimensions (LxWxH): 600x400x500mm Weight: 40 kg Pump aggregate NP 25/50 Performance Min./Max.: 400-1000 kg/h Power cons.: 3,0 kW Motor: 3x400 V, 50/60 Hz Drive: V-Belt Dimensions (LxWxH): 800x600x500mm Weight: 85 kg Pump aggregate NP 25/70 Performance Min./Max.: 600-1500 kg/h Power cons.: 4,0 KW Motor: 3x400 V, 50/60 Hz Drive: V-Belt Dimensions (LxWxH):800x600x500mm Weight: 85 kg The following stats are valid for all pumps: Materials Valve casing: Special brass / cast bronze Valves: High grade stainless steel Plunger: Ceramic Sleeves: CO 2/N 2O – resistant compound; fabric reinforced Support rings: Teflon with graphite, run-dry-proof Crankshaft: Drop-forged and case hardened Pump

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Bush conveyor chains are often used for conveying tasksinvolving long transport distances at relatively low speeds. Since only a small minority of chains used in the industry are totally compliant with one specific standard, ELITE conveyor chains are custom-made to a specific customer order and consequently fulfil a large number of special requirements. ELITE highlights: • Pins usually made of heat-treated alloy steel, inductionhardened • Bushes made from seamless precision steel tube, case-hardened • Link plates made of high-strength tempered steel or case-hardened steel alloy • Rollers (where present) made of case-hardened steel, case-hardened

Request for a quote

IBG HYDROTECH GMBH

Germany

The Drakula universal cleaning nozzle made of case-hardened VA steel with large jet angles for pipe and sewer cleaning is particularly suitable for standard cleaning.

Request for a quote

ZWICKROELL GMBH & CO. KG

Germany

The ZHV10 is a unit that deals with determining Vickers, Knoop, Ritz, and Brinell hardness levels, case hardening, and nitride hardening depth. This unit is available in two versions, and is fitted with an analog instrument. This allows operators to evaluate the hardness rating based on a table of values. Moreover, this unit is engineered with the capability of dealing with operations that are concerned with loads that range from 0.2 to 10 kg.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Highlights: • Wide range of products • Dimensions according to ISO 1275 • Versions with small rollers and transport rollers available • All ELITE chain plates 1 are manufactured using processes such as fine blanking and ball-drifting, so a particularly high Product range: • Double pitch roller chains ISO 1275 • Double pitch roller chains with straight plates ISO 1275 • Double pitch hollow pin bushed chains • Double pitch hollow pin roller chains contact ratio is guaranteed. • Solid, case hardened rollers 2 with good wear resistance • ELITE pins 3 are smooth and have an extra hard surface for increased wear resistance

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Many ELITE hollow pin chains are constructed to the dimensionsof standard ISO 606. Since customer requirements are so diverse, the ELITE product range has also been adapted to include various versions of this chain type: • Hollow pin roller chains • Hollow pin bush chains • Bushless hollow pin roller chains ELITE highlights: • Available based on the same chains manufactured to ISO 606 or as special chains • All ELITE chain plates 1 are manufactured using processes such as fine blanking and ball-drifting, so a particularly high contact ratio is guaranteed. • Solid, case hardened rollers 2 with good wear resistance • In general, hollow pins 3 made of seamless precision steel tube for improved precision and wear resistance • Many of these chains are supplied pair-matched to ensure exact parallel running, one of the main requirements that these chains must fulfil.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

ELITE roller chains with sawtooth plates are extremely wearresistant and designed for optimum fatigue strength. They are used mainly in the wood processing industry for transporting raw timber and sawn planks. ELITE highlights: • Our chains are based on the minimum requirements set out in standard ISO 606. • The steel alloys used are case-hardened and tempered. • Heat treatment of all chain parts is optimized to suit size and application • All roller chains are prestretched to >40% of breaking load as standard • The high quality assurance standard fulfils the requirements of ISO 9001 • Plates 1 are shot-blasted for maximum fatigue strength • Seamless, cold-extruded, shot-blasted rollers 2 with extremely regular wall thickness • ELITE pins 3 are smooth and have an extra hard surface for increased wear resistance

Request for a quote

ZINNER GMBH PRÄZISIONSWERKZEUGE

Germany

CBN (cubic boron nitride) is the next hardest material after diamonds. When properly used, tools made from CBN exhibit considerably less wear than other materials. Cutting inserts or even VHM tools can be equipped with CBN. Technical application: Hardened tool steels with hardnesses greater than 55 HRC or high speed steels (HSS) can be machined without problems using CBN. Case hardened steels and chilled cast iron can also be machined with CBN. Non-ferrous metals are totally unsuitable for CBN; diamond tools are needed for these.

Request for a quote

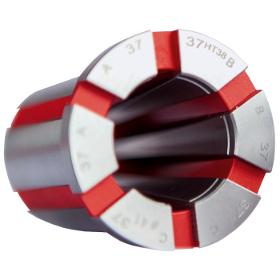

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

In terms of precision, stability, and flexibility the vulcanized segmented clamping bushings are unbeatable. They consist of segments made of chrome/nickel, case hardened steel that is very hard, extremely wear resistant, and rigid [60 HRC]. Plus, they do not have to »bend« to clamp the workpiece. In addition, all functional surfaces are completely ground in one clamping set-up. The result: maximum run-out accuracy, maximum holding power, and long life span.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Whether lathe or machining center Complete machining made easy: You cannot only use our MANDO and MAXXOS segmented mandrels on the lathe, you can also use them in stationary mode. Simply screw the mandrel onto the ms dock [manually actuated] or hs dock [hydraulically actuated] and you can clamp your workpiece from the inside, stationary mode. Precise, without vibration and with minimum set-up effort. The extremely wear-resistant segmented clamping bushing of case-hardened chromium-nickel-steel with the rubber between the segments, especially developed by HAINBUCH, makes it possible. Manual actuating unit ms dock The hand-actuated ms dock in conjunction with stationary MANDO and MAXXOS segmented mandrels is ideal for machining centers, measuring machines, radial drill presses, parallel and angle plate clamping or for clamping on dividing heads. The version ms dock rotating can be used on turning and grinding machines until RPM 1/min.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

Extremely high clamping force Often complete machining fails for lack of an effective I.D. clamping device. In many cases the jaw chuck is a makeshift solution. However, even conventional mandrels with slotted clamping sleeves quickly reach their limits in terms of accuracy, rigidity, and opening stroke. HAINBUCH segmented mandrels use state-of-the-art clamping technology that is convincing, even in the most critical applications. Segmented clamping bushing with extremely hard, wear resistant and rigid segments The central element is the vulcanized segmented clamping bushing. Because conventional clamping bushings are made of spring steel and are only annealed to spring hardness, they are »soft« and they must »bend« to clamp the workpiece. HAINBUCH segmented bushings, on the other hand, are made of case-hardened chromium-nickel-steel and have segments that are extremely hard, wear resistant and rigid.

Request for a quote

ASSFALG GMBH

Germany

The sturdy and easy chamfering machine is designed for deburring and chamfering of small to large workpieces from 2 mm thickness. The sturdy cast iron casing, the hardened and sanded guide rails, the speed regulation and the integrated chip box convince in every regard. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clatter-free, clean and constant chamfering. A chamfer width of up to 10 mm is possible in NE metals and a chamfer width of up to 5mm in steel. Hardened workpieces, HSS and hard metal materials can be processed through optional CBN and diamond grinding discs. For longer workpieces or serial part production, we recommend optimizing the feed unit with pressing pressure, surface quality, feed speed and service life of tools. The machine can be installed on an undercarriage for flexible use in a workshop.

Request for a quoteResults for

Case hardening - Import exportNumber of results

22 ProductsCountries

Company type

Category