- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- capping machines

Results for

Capping machines - Import export

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 8000 capping machines are specifically engineered for aseptic filling and ultra clean applications. These cappers incorporate full stainless steel construction and the most advanced corrosion-resistant materials. The open design facilitates cleaning and rinsing to optimize hygiene levels. Series 8000 machines are fully metric, perfect for global use and are suitable for plastic and aluminum caps. High Performance Features for "Aseptic" Capping Full stainless steel construction to prevent corrosion Open design for ease of cleaning and 100% rinsing Pick station drive unit designed with sloping surfaces and lubricant-free hybrid bearings to maintain cleanliness Pick station provides precision closure delivery with minimal contact points to improve hygiene Lubrication free spindles utilizing state of the art materials and design technologies to provide extended and predictable maintenance intervals of 4,500 hours Headsets specifically developed...

CL MACHINERY GMBH

Germany

With its full stainless steal and modular construction, Closure Systems International's Series 5000 Combi Capping Machine is recognized in the industry for its reliability, low maintenance, and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum, and PET bottles. In fact, Series 5000 Combi, allows plastic closures (CIH) and metal roll-on caps to be applied on the same capper using the same spindle. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM.

CL MACHINERY GMBH

Germany

With its full stainless steel and modular construction, Closure Systems International’s Series 5000 capping machine is recognized in the industry for its reliability, low maintenance and flexibility. This durable and versatile capper allows bottlers to effectively apply a wide variety of closures, especially aluminum caps, including: TSROPP, ROPP, screw caps, lug caps, Ring Pulls, and T-Corks for glass, aluminum and PET bottles. Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stainless steel turret Stainless steel spindles with wear-resistant plastics Stainless steel headsets New modular spindle assembly Proven headset designs for highly consistent closure application and torque control High throughput Plastic: 42 BPM / 2,520 BPH per head Roll On: 50 BPM / 3,000 BPH per head CSI Cap-in-Head technology assures proper closure placement at high speeds for optimized cap application Direct integration.

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 900T capping machines are designed for reliability, low maintenance and flexibility. The machines’ high performance and flexibility allow bottlers to apply plastic closures for a wide variety of applications at the highest possible speeds. The capper’s stainless steel construction and easy-maintenance features help reduce bottlers’ total cost of operations. Best Reliability & Robustness Robust, durable construction for long-lasting performance Proven headset designs for consistent application and torque control Full stainless steel design Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter, and other bottling line equipment choices Integrated PLC with touch screen to monitor application conditions and provide effortless user interface Auxiliary closure buffer for unexpected interruptions Quick, Easy Maintenance & Changeovers Simplified low maintenance requirements to reduce...

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 501 Capper is a single head capping machine that operates in a manual configuration for sealing bottles and containers of various shapes and sizes. The Series 501 bottle capper is popular for custom package applications and small volume production, such as in performance laboratory and research environments. Simple Operation Can quickly and easily change package and closure sizes on the single head by adjusting the bottle stop and operation height Bottles and closures are positioned manually, allowing for automatic capping by the lowering of the headset onto the bottle finish High Performance Standard Features Neck support assembly Bottle control support increases package size range for small bottles Available with single stroke or two-stroke options for lightweight aluminum packages Versatile & Customizable Can be configured for a wide variety of closure types, including plastic closures and aluminum roll-on caps; includes parts for quick.

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 200E capping machines are recognized as the "workhorse" of the capping industry for their reliability and low maintenance. The proven performance and flexibility allows bottlers to apply plastic and aluminum closures for a wide variety of applications at the highest possible speeds. Best Reliability & Robustness Robust, durable construction for long-lasting performance Proven headset designs for consistent application and torque control Corrosion-resistant materials in product zone; full stainless steel option Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter and other bottling line equipment choices Integrated PLC with touch screen to monitor application conditions and provide effortless user interface Auxiliary closure buffer for unexpected interruptions Quick, Easy Maintenance & Changeovers Simplified low maintenance requirements to reduce downtime Totally enclosed washable...

CL MACHINERY GMBH

Germany

Closure Systems International’s Series 200 bottle cappers are the ultimate for aluminum roll-on applications. CSI's custom-engineered and precision built Series 200 cappers have been the preferred choice of the beverage and beer industry for decades. Industry’s Best TSROPP Performance Two cams provide independent control of top seal and thread forming, allowing precise control for specialty aluminum / roll-on packaging Perfect for roll-on closures requiring top/side sealing Robust, durable construction for long-lasting performance Corrosion-resistant materials in product zone; full stainless steel option Direct integration with any filler: various custom drive systems and pitch diameters to match filler, sorter and other bottling line equipment choices Open design for ease of cleaning Easy removal spindle assembles for quick maintenance Industry leader in Alumitec Application High-Speed, Consistent Application Industry-leading throughput at 50 BPM / 3,000 BPH per head Proven...

CL MACHINERY GMBH

Germany

Closure Systems International's Intelli-Torq Servo cappers set the standard for plastic closure application quality control, guaranteeing safer and more efficient production. These cappers incorporate full stainless steel construction and have an open design that facilitates cleaning and rinsing. CSI's Intelli-Torq Servo Cappers are also fully metric, perfect for global use. Intelligent Capping for Maximum Efficiency Pre-set application recipes In-line quality control for product assurance and proof that only perfect products leave production lines Computer-controlled capping with monitoring of application torques and angles Application torques documented on a continual basis Detection and removal of defective product, minimizing risk of product liability claims Data storage Highest quality assurance, control and cost savings Reliable & Robust Robust, durable construction for long-lasting performance Full stainless steel construction to prevent corrosion Stationary servo motors..

CL MACHINERY GMBH

Germany

Closure Systems International’s PP136 Capper is a single head capping machine that operates in a manual configuration for sealing bottles and containers of various shapes and sizes. The PP136 bottle capper is popular for custom package applications and small volume production, such as in performance laboratory and research environments. Simple Operation Can quickly and easily change package and closure sizes on the single head by adjusting the bottle stop and operation height Bottles and closures are positioned manually, allowing for automatic capping by lowering the headset onto the bottle finish High Performance Standard Features Neck support assembly Bottle control support increases package size range for small bottles Robust construction: machine body made of cast iron Versatile & Customizable Can be configured for a wide variety of closure types, including plastic closures and aluminum roll-on caps; includes parts for quick changeover Can be designed for many package...

FILLPACK GMBH & CO. KG

Germany

Filling and sealing machine for viscous products Machine performance: 40 cycles/min. max. 2 400 jars/h Special features: Dosing pump with motorised adjustment from 0-500 ml Film applicator station Sealing station Capping station

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2400 is a fully automated, linear motor driven, filling, foil application, foil sealing and capping machine, suitable for creamy to liquid filling media. Capacity: 35-40 pcs per minute Available versions: Fill/Seal, Fill/Cap, Seal/Cap, Fill/Seal/Cap machine frame from aluminium profile indexing transport system for jars horizontally working conveyor for jar infeed and discharge position control for jars in indexing rotary transport dosing pump from 1.4404 10 l hopper with level control filling nozzles driven by LinMot-e-motor pick and place system for pre-cut foils from magazines driven by LinMot-e-motor 1 spot sealer to fix the foil at the sealing rim of the jars sealing system with conduction sealing head capping station with LinMot-e-motor infeed conveyor for caps electric cabinet with operation panel manual central lubrication system safety doors with aluminium profile frame and windows from makrolon

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling, sealing and capping machine for viscous products Capacity of the machine: 60 cycles/min. max. 3.600 jars/h Special features: Dosing pump with motorised Adjustment from 0 – 500 ml Heatable hopper with agitatork Output of the filled jars to the cooling tunnel and return to machine for sealing and capping Heatable filling nozzle with recovery system (drip-free) Foil lay-on station (from foil magazines or with punching tool) Sealing station (conduktive system or induction sealing) Capping station

Request for a quote

CL MACHINERY GMBH

Germany

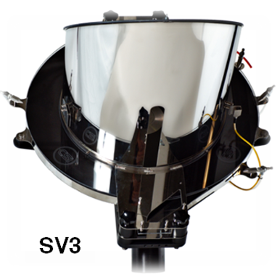

Closure Systems International's SV Series Rotary Sorters are simple to operate and keep your capping operation running smoothly. CSI's robust, efficient rotary sorter designs allow only correctly oriented closures to be fed through the cap chute for unsurpassed capping reliability. CSI Rotary Sorter High Performance Features Maximum versatility: can be either post-mounted in mezzanine or mounted on top of CSI capping machines SV2, SV3 and SV21 designed to orient flat closures, plastic and aluminum, ranging in diameter from 20mm to 38mm SV131 and SV197 designed to orient both flat closures, plastic and aluminum, ranging in diameter from 20mm to 55mm SV813 - 815, SV32, SV41, and SV50 designed to orient both flat and sport closures as well as wider diameter closures, up to 110mm Simple changeovers: accomplished by flipping a switch Sorting speed approximations (based on 28mm caps): ✓ SV2: 350 caps per minute ✓ SV3: 750 caps per minute ✓ SV21: 950 caps per minute ✓ SV41: 600 caps per...

CL MACHINERY GMBH

Germany

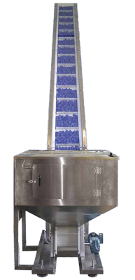

Closure Systems International's closure elevator pre-feeders are designed to feed closures to sorters from the ground level. Via a cleated belt, closures are fed from a bulk storage bin at ground level to a sorter mounted on a capping machine. CSI Closure Pre-Feeder Features & Benefits Stainless steel construction Bin sizes available: ✓ 10 cubic feet ✓ 25 cubic feet ✓ 50 cubic feet ✓ 100 cubic feet Can be custom designed to meet any delivery rate Can be custom designed for any closure size and type Clean-out door for quick changeover Lexan bin cover for clear visibility Lexan conveyor cover to keep dust out High and low level photo sensors Self-contained stainless steel control panel Controls can be integrated with capper controls Best to be combined with a rotary sorter and placed next to the capper Markets Served: Beverages, Food, Pharmaceutical, Automotive Fluids, Personal Care, Home Care, and Custom Applications Unmatched Technical Support / Application Expertise!

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. Our machine can handle a large type of vial bottles , types and shapes SPECIFICATION Machine is made up to the international GMP regulations Turn table feeding system Type of metal used S.S 316 Double Sterilizing nozzles system before and after filling. 2 diving filling nozzles 2 Peristaltic pumps Double star filling and capping system Double caps vibrator feeding system 1 Rubber vial stopper mushroom, 2 aluminum flip caps Rotary capping servo system Delaying bottles conveyor system Herma labeling head HMI and SCADA system with interactive touch screen control system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q , O.Q , P.Q, DQ.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Bottles and caps sizes, types and shapes Type of metal used S.S 316/304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple gallon size, types and shapes Type of metal used S.S 316/304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Pneumomechanical Barrel feeding system Volumetric filling system One head Diving nozzles filling technology Servo conveyor system with multiple speed technology. Low to high viscosity Cut and seal system Multiple roll types can be handled. MechanicPneumatic capping system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, FDA. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION compact design. made up to our German technology, to meet all the international and the European standards. One side labeling machine with coding, dating system Our machine can handle a large type of label, Bottles, and caps Types, size and shapes. SPECIFICATION Pneumatic paddle Volumetric filling system Type of metal used S.S 316 Labeling head. Pneumatic capping gun Drawer feeding caps Label coding system Mechanical weight adjustment system Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Continuous rotary blowing machine 6 heads diving filling nozzles Star sterilizing capping and closing system Herma Labeling machine 1 heads One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 2 diving filling nozzles Star capping and closing system Labeling machine 1 head HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION the machine has been made with a compact design. Machine can handle multiple bottles type and size. Capping and closing star system (for compact design). Servo star system. Servo closing system. Bottles Sterilization system SPECIFICATION 2 Filling nozzles Servo conveyor system included Type of metal used S.S 316 for all product contact metal parts & S.S 304 for all uncontacted product parts HMI and Scada system. Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple barrel size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION One barrel feeding turn table One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system. 6 heads Diving filling nozzles Capping system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple gallon size, types and shapes Type of metal used S.S 316 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION One gallon feeding turn table One collecting table HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system. 4 heads filling nozzles Sealing and capping star section.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 2 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system UV sterilizer system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Volumetric filling system SCADA and HMI with a touch screen system 1 head filling nozzle Cups feeder system Sealers feeding system Sealing system Caps feeder system Capping system Servo conveyor system Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quoteResults for

Capping machines - Import exportNumber of results

44 ProductsCountries

Company type

Category

- Food industry - machinery and equipment (22)

- Bottling and filling - machinery and equipment (2)

- Packing and packaging - machinery and equipment (2)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Rolling mills - machinery and installations (2)

- Automation - systems and equipment (1)

- Cheese-making machinery (1)

- Dairies - machinery and equipment (1)

- Package stamping machinery (1)

- Pad printing (1)