- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brush rollers

Results for

Brush rollers - Import export

GURTEC GMBH

Germany

Hydraulic operated Rotational speed of brush: max. 150 RPM Can be adjusted by hydraulic pump – brush will be lifted to operation position by hydraulic cylinder and keep same pressure against the belt

Request for a quote

KULLEN-KOTI GMBH

Germany

Roller brushes Type 422 with sub-bodies e. g. tubular cores with journals are defined as having a body length longer than 100 mm (for brushes shorter than 100 mm, see "Circular brushes"). The brush cores (plastic or wooden cores with mechanically anchored bundle of fill material) either are mounted on steel shafts (WK1) or Steel /stainless steel tabular cores with journals (WK1 resp. WK4) for strength and rigidity. The comprehensive range of dimensions, core materials, fill materials and fill configurations demonstrates the versability of Kullen-Koti again and again. We would be pleased to supply you on request with details of special designs with wood or metal bodies. In case of brushes with non-cylindrical cores, we would like to ask you to send us a drawing or simply discuss your requirements with our technical consultant. Fill material densities: - High fill density EA1, - normal fill density EA2, - low fill density EA3. Fill configurations: In addition to a full fill...

Request for a quote

KULLEN-KOTI GMBH

Germany

Roller brushes Type 421 without a sub-body are defined as having a body length longer than 100 mm (for brushes shorter than 100 mm, see "Circular brushes"). The comprehensive range of dimensions, core materials, fill materials and fill configurations demonstrates the versability of Kullen-Koti again and again. But you should bear in mind that often a brush with a standard core diameter is more reasonable in price and can be supplied much quicker. The brush cores can be produced with plain bores for shaft mounting, as well as with keyways, dowel pin holes, internal or external threads and reducing bushes. In case of those special requests we would like to ask you to send us a drawing or simply discuss your requirements with our technical consultant. The max. circumferential speed for this brush type is 15 m/sec. Fill material densities: High fill density EA1, normal fill density EA2, low fill density EA3. Fill configurations: In addition to a full fill configuration in three...

Request for a quote

KULLEN-KOTI GMBH

Germany

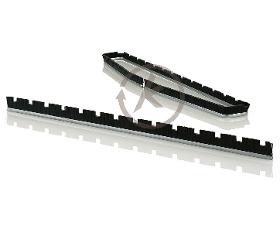

Kullen-Koti roller brushes 302 are indeed unique and easy-to-handle: you only purchase the roller brush core once and easily refill it yourself with the corresponding strip brushes after wear. And besides, it is a very economical brush system. The ruged construction allows problem-free operation also in adverse conditions. Roller brushes type 302 consit of a tubular steel or stainless steel core and exchangeable strip brushes which are mounted in axial direction around the circumference. The brush core can be supplied either with journals or with arbor hole for mounting on the existing primary shaft. With the roller brush type 302 (mS) the strip brushes are fixed in side flanges. With type 302 (oS) the strip brushes are fixed directly on the tubular core with clamping plates. Fill configuration to choose: bent in axial direction, left-hand or right-hand pitch or in chevron pattern i. e. left hand and right-hand pitch starting at the centre. Strip brushes needed around the...

Request for a quote

KULLEN-KOTI GMBH

Germany

The KULLEN roller brush type 350 is one of our "highlights" as it consists of a lightweight aluminium core with horizontal grooves where strip brushes are fitted in.Two standardized aluminium cores are available:For our brush type 350/54 with 20 horizontal grooves,which means the brush consists of max. 20 strip brushes around the circumference.For our brush type 350/85 with 36 horizontal grooves, which means the brush consists of max. 36 strip brushes around the circumference. The fill configuration is either dense (EC1) or light (EC2) which means an axial strip configuration.You can use almost alll type of fill material except synthetic bristles exceeding dia. 0.60 mm and wires exceeding dia. 0.20 mm. The strip brushes for the roller brush types 350 are mounted in the profiled aluminium tube cores - either with standard bore (AL 31 resp. 60 mm) to be seated on a primary shaft. - or with reduced bore by bushes to be seated on a primary shaft. - or with journals.

Request for a quote

KULLEN-KOTI GMBH

Germany

The roller brush type 964 is made of single section brushes mounted together on a core up to the required face width. This roller brush type can be mounted on cores made from stainless steel, plastic coated steel, or mild steel. Kullen-Koti recommends especially this brush type for heavy-duty operations with a high dense brush surface, e. g. by using our single section brushes with twisted steel knots (Type Z-SH). But we can manufacure the single section in almost all other fill material types. For mounting the single section brushes on the core or by the operator himself on the existing primary shaft, we use our fixing ring (FRB / scew nut (MB) system. The single section brushes are available in 10 particular series-diameter (KD.) The single section brushes can be supplied as roller brushes type 964 with the following core systems: - system WK 1/WK 2 with journals. - tubular core with reduction bushes (WK 3). - "Throw-Away" system with thin-walked tube with arbor hole fitting on...

Request for a quote

KULLEN-KOTI GMBH

Germany

The STS-spiral roller brush range from Kullen-Koti contains all measurements from small to extra large and this unbeatable selection of diameters makes this brush a totally reliable tool for light brushing tasks. Due to the high fill density and precisely ground surface it achieves outstanding results. A flawless radial true runing is a requirement in most cases to achieve the desired brush effect. Therefore the brush cores are electrodynamically pre-balanced and re-balanced according to the required RPM after assembly of the spiral brushes. The balancing quality refers to quality grade G 2.5 as per ISO 1940. As core material we have available: mild steel, stainless steel, non-ferrous metal or plastic coated steel. Fixing of the spiral coils The coils are generally mounted onto the roller cores with pressure rings (PRB) in order to prevent the brush from roating on the core. Depending on the work and the rotation speed of the brush the coils can also be spot-welded or screwed...

Request for a quote

KULLEN-KOTI GMBH

Germany

The ST-system above all is suitable for roller brushes fitted to a shaft or tubular core with journals made of steel or stainless steel (1.4301; 1.4541). All available fill material qualities and fill configurations can be used.The available core systems are: shaft WK1, tubular core WK2 resp. WK4.The maximum peripheral speed for this brush type is 15 m/sec. Fill Densities high fill density EA1, medium fill density EA2, low fill density EA3. Fill Configurations Compressed face EA1 - EA3, spiral EB and strips ED1.

Request for a quote

KULLEN-KOTI GMBH

Germany

The types 220 & 221 are extremly flexible in their dimension and depending on the required performance these endless spiral brush coils are mounted on core systems made of mild steel, stainless steel or non ferrous metals.Compared with other brush designs we can reach the highest possible fill density with these types and they can be applied with a maximum speed of 55 m/sec without any problems. Supposition for it, is that the roller brush cores are electrodynamically balanced after the mounting of the core according to the required rotation speed and quality G 2.5 which comes up to ISO 1940. Our roller brushes are supplied with a fill surface perfectly trimmed and/or ground for concentricity. A perfectly seated attachment of the coils on the roller core is guaranteed by the pressure or mounting ring (PRB) system, also available with removable balancing weights (PRB-AW), which prevents the brush coil from rotating on the core. In some circumstances you also could choose a...

Request for a quote

KULLEN-KOTI GMBH

Germany

A further variation of the "Throw-Away" system is type 230. It consists of continuously wound DBS-spiral brushes fitted to a thin walled steel, stainless steel or non-ferrous metal tubular shaft. The face width corresponds to the required total brush legth (BLG). The complete "Throw-Away" brushes can be simply assembled onto the customer's existing shaft. This method avoids the costly return of the complete shafts when the brushes have to be replaced. Core systems The complete "Throw-away" brushes type 230 can be supplied with adaptors to reduce the core inside diameter (KD) i. e. brushes with or without collar with suitable arbor holes (AL) for the different core systems WK1 and WK2. Our roller brushes are supplied with a fill surface perfectly trimmed and/or ground for concentricity. The brushes with adaptor or bushes are electro-dynamically balanced at the intended rotation speed according to standard G 2.5 as per ISO 1940

Request for a quote

WALDKRAFT GMBH - BÜRSTEN- UND KUNSTSTOFFTECHNIK

Germany

We are not only active in the field of classic brushes. This is how we make brushes for technical needs. The product range is very diverse. They are often specially made customer brushes. They include rollers and plates made of any materials and shapes.

Request for a quote

R&S PAPIERVERARBEITUNGS-GMBH

Germany

You will find: Combination nozzle with tilt and turn joint and thread lifter in different working widths and pipe diameters. Combination nozzle with butt edge gentle on furniture with swivel joint and thread lifter, various pipe diameters Turbo nozzle with brush roller, tilt and turn joint and rollers with different tube diameters Nozzle flat design with tilt and turn joint and two thread lifters

Request for a quote

KULLEN-KOTI GMBH

Germany

The removal of dust and electrostatic charges - we lead the way. Rotary ostrich-feather roller brushes remove dust from workpiece surfaces in accordance with a simple and reliable principle - due to their intrinsic electrostatic charge, the feathers lift dust from the workpiece surface. Gently and thoroughly. The dust ionised in this way remains on the feathers until removed by a suitable dust extraction system. Ostrich-feather roller brushes of Kullen-Koti consist of circular brush segments with standardised wooden cores, assembled to the requested face width and especially formed brush diameter for the car bodies. By using different outer diameters the roller brush can be adapted to the outline of the workpiece surface which is to be dedusted. Just contact us - without obligation - if you have any requirements.

Request for a quote

KULLEN-KOTI GMBH

Germany

Our brushing machine type BM 1138 has been constructed previously for heavy-duty conveyor belt cleaning in coal mines and foundries. Today we supply it for almost all kinds of industry where conveyor belts have to be cleaned. BM1138-characteristics The particular criteria are: - rugged machine core in welded construction. - high cleaning performance. - minimum belt wear. - small assembly dimensions. - easy retrofitting. - simple mounting to all carrier systems. - integrated vertical adjustment of roller brush. - exchange of the brush coils without removing the roller brush. The brushing machine can be installed at the converyors according position 1-8.

Request for a quote

KULLEN-KOTI GMBH

Germany

The brush cores are made of special reinforced polypropylene making them light, resistant to acids and alkalis and suitable for use in the food industry. The range of options is extensive. All in all we offer seven standard core diameters with three fill density variations each: low, medium, and high - making a total of twenty one standard cores to choose from. Almost all fill material qualities can be used. To assemble a complete roller brush is remarkably quick an easy as it does not involve any complicated mechanical connections, simply slide the brush segments on to the brush shaft and secure them in position with two locking collars. By standarding the sizes of our brush cores we are able to offer lower unit prices and faster delivery times. But the fact that our brush carrier sizes are standardised certainly does not mean that the choice we offer is limited. If required the standard internal bore diameter of the brush segments and locking collars can easily be reduced by...

Request for a quote

KULLEN-KOTI GMBH

Germany

The STS-spiral coil is the only brush type that can be produced with very small diameters starting at an overall diameter of 17 mm. Offering an enormous choice of dimensions and fill material qualities this brush has almost unlimited applications in light or medium work. The long period of development of this brush type has left its mark and appears in every detail of the brush. The diagram below shows how the STS coil is constructed: the fill material is fixed with a locking wire inside the backing tape. Available backing tapes We manufacture the STS-brush in eight different coil widths (WB) from 2.5 mm to 13.5 mm. As material we use mild steel, stainless steel (1.4301, 1.4571) or brass. STS-spiral coils can be supplied for self installation, as well as a complete roller brush with shaft. Variety The STS-spiral brush offering an enormous choice of fill material, fill arrangements and fill densities. Depending on the fill material and dimension we can also increase the density by...

Request for a quote

KULLEN-KOTI GMBH

Germany

Our roller brush coil designed as welded package system will also pack the tiger in your tank! Why is it reasonable and advantageous to purchase a welded package system type 231? Each face width of a roller brush needed can be divided in a corresponding number of single, compact segments, called packages, that are not only loosley coiled spirals. What we produce are light and easy-to-handle packages with a constant high density which facilitates and accelerates the equipping of a brush core or shaft carried out by yourself.The welded package system is not only easy to mount but it also makes you independent of any transportation of the core to the supplier for refilling, packing, delivery times etc. and helps you out of emergency situations.For the core constructions the following materials are available: plastic-coated steel, steel, stainless steel (1.4301; 1.4571; 2.4879). The twin tape mounting is designed as a concave backing system where the coil widths (WB) ranges between...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

R&S PAPIERVERARBEITUNGS-GMBH

Germany

You will find: Hard floor nozzle with swivel joint, two brush strips and two casters in different working widths and pipe diameters. Hard floor nozzle with horsehair with swivel joint, two brush strips and two rollers in different working widths and pipe diameters Wet floor nozzle with swivel joint, two rubber strips and two rollers with different working widths and pipe diameters

Request for a quote

KULLEN-KOTI GMBH

Germany

Our special types consist of 10 types of strip brushes with metal backing widths from 1,8 mm to 13,5 mm, which we can produce in a large range of variations.You can choose:- All fill types, e.g. natural bristles and hair, plant fibres, wires and synthetic filaments. - The backing strip material made of galvanized steel, stainless steel (1.4301, 1.4571) or brass.- The trim height (BH) (free bristle length)- The overall length from a few centimeters to the maximum length which can be transported. The strip brush type 60 will mainly be mounted in half-rings with various numbers of grooves around the periphery and therefore used as a roller brush. The ring diameters are 80 mm, 100 mm and 102 mm. We can supply holders for fixing the strip brush type 25 and type 40.

Request for a quote

KULLEN-KOTI GMBH

Germany

The bristles of strip brushes are fitted in a metal backing tape. This allows the brushes to be mounted by means of holders or inserted into grooves. For example, as replacements for special circular and roller brushes. We supply all standard types in a length of 1.000 mm. We can supply seperate holders for fixing our strip brushes type 25 and type 40. The standard types are produced with backing strips of galvanized steel and filled with polyamide bristles (PA6) resp. mane hair (MAH). If your application allows we recommend you to use our standard types available from stock.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Standard advantages: RTS-Rotation – low-maintenance dry spray booth Overspray dry separation demonstrates its strengths in practice above all when relatively large quantities of paint have to be processed and the overspray portion cannot be reduced any further. Spray booth with dry separation are usually equipped with disposable filters or manually regenerative filters. These cause costs for spare filters, maintenance and disposal. In addition to that, operation has to be interrupted in order to exchange the filters. The ‘RTS rotation’ system was developed by Rippert in order to reduce these costs and tooling times. Maintenance intervals and filter service lives are prolonged significantly in comparison with conventional systems due to the new brush pre-filtration. How the ‘RTS-Rotation’ system works Overspray separation in the RTS-Rotation system takes place by means of a pre-filter and a fine filter stage. The pre-filter stage is formed by vertical, slowly rotating brush rollers. The bristles present a very large total surface area and absorb the adhesive particles from the overspray. During the slow rotation, the paint particles can dry on the tips of the bristles. This results in slowly growing cakings on the bristles. Scrapers are mounted in the area behind the brush rollers that continuously remove these cakings from the bristles. The dislodged, hardened material falls into the drawers arranged under the brushes and can thus be simply disposed of. The dry paint dust may often be disposed of as ‘commercial waste’. The brushes otherwise require little maintenance and do not need to be exchanged or renewed. The fine filter stage is formed by a special fleece filter, which is arranged above the brush rollers and must be manually maintained or exchanged in the standard version. The maintenance intervals depend on the paint material used. Automatic cleaning or an external fine filter with automatic cleaning is also possible as an option. Over 10 years of operational experience shows that around 75 to 95% of the overspray is separated out by the pre-filter stage and the rest by the fine filter stage. The degree of separation depends strongly on the type of paint and the drying reactivity during the flying phase. Use of the RTS-Rotation with the following paints Before practical use, the paints are tested and approved in Rippert’s own pilot plant. Stove enamels and 100% UV paint systems cannot be used. The horizontal version Furthermore, it is possible to use the system as a horizontal underfloor extraction system. This version is used, for example, by a machine manufacturer for large parts. In addition, a drag conveyor with gulley extraction is used there in order to automatically transport the particles cleaned off the brushes out of the pit. Conclusion The RTS-Rotation system is particularly useful when relatively large quantities of paint with an unavoidable overspray portion have to be processed, as otherwise a great deal of residual waste would result using conventional technology. Compared to water-sprinkled spray walls and normal dry spray booths the amortisation period is shorter; it is frequently less than two years.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

With high-quality filter tubes and PTFE diaphragms. Paint dust filters Wet painting also results in overspray. Overspray is the solid portion of the paint that is not taken up by the workpiece. According to the purpose of use, the overspray is moist and sticky immediately after release. It is captured by the exhaust air stream in the spray booth and fed to a filter. This can be, for example, a baffle plate filter, paper filter, fleece filter, glass fibre filter or also combinations of these. The adhesive effect causes the paint particles to adhere to the contact surfaces of the respective filter medium, as a result of which a good degree of separation is achieved. However, all these filters are storage filters, i.e. the filters clog up more and more during operation and cannot be regenerated. A filter exchange becomes necessary if the exhaust air rate of the spray booth falls below the minimum. This can be very time-consuming under certain circumstances and the work process must be interrupted in order to do it. To make things worse, not only must the filtered and bound paint residues be disposed of, but also the actual filter materials. Such tooling times are not justifiable for automatic, continuous or multi-layer painting processes. Continuous procedures such as automatically cleaned filters are likewise required for this. The humidity and the adhesiveness of the particles to be filtered are thereby the problem. In order to solve this problem, the paint particles should be relieved of their adhesive capability as far as possible whilst still inside the paint booth. Our patented ‘RTS-Rotation’ system is outstandingly well suited for this. The system is comprised of slowly rotating brush rollers, which take up the adhesive paint particles on the surface of the bristles and allow them to dry there. The bristles are automatically regenerated at pre-specified time intervals by combing devices that swing in at the rear of the brush rollers. The dislodged paint residues can then be removed and disposed of either manually during work breaks or automatically during operation. The degree of separation of this system is, however, insufficient to satisfy the environmental protection requirements concerning residual dust content in the exhaust air. A further filter stage is necessary for that. It must be assumed that the paint particles arriving here are to a certain extent still damp and sticky. For this we use special paint dust filters with high-quality filter tubes with PTFE diaphragms. If necessary, precoating agents (auxiliary dust) are used in order to neutralise the adhesive capability of the particles and to keep the dust layer on the filter elements permeable to air. The precoating agent is injected into the raw air pipe by means of special dosing units. The filter tubes are cleaned by means of compressed air impulse cleaning. The use of this technology requires special know-how. We have had the appropriate experience for almost ten years. The implemented plants have capacities ranging from 5,000 to 90,000 m³ /h. Because of the large number of different paint systems, individual experiments are usually necessary in our pilot plant in order to find the correct solution for the individual case.

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

Machines for special purposes are manufactured specifically according to the customer’s wishes. Roller brushes over 4 m in length, with or without incline. Our wide range of special machines includes large disc-type brushes with different drilling diameters.

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

Universal machines allow you to produce all different types of brushes – from brooms to toilet brushes, from disc-type brushes to roller brushes. Everything is possible thanks to the universally replaceable changeable frame.

Request for a quoteResults for

Brush rollers - Import exportNumber of results

28 ProductsCountries

Company type