- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- brake motors

Results for

Brake motors - Import export

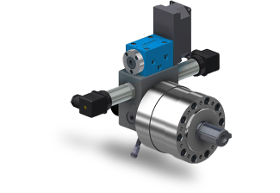

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors of the HSE series also fulfill the function of end position damping with or without adjustable swivel angle limitation. This refers to braking, the deceleration of the swivel movement to a standstill. For damping, the cross-section of the bore for the outflowing medium is continuously reduced, thus hydraulically slowing down the moving masses. The end position is reached when the hole is completely closed and the medium can no longer flow out. In order to provide our customers with the right drive for all areas of application, the HSE swivel motor is available in a total of 6 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

IGUS® GMBH

Germany

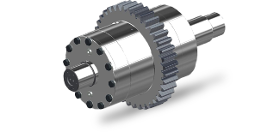

Planetary gears for igus® stepper motors NEMA 23, 23XL & 34 Increased motor torque Increased brake holding torque 2 installation sizes Reduction gearing of 3 & 5 available Typical applications:Packaging technology, general mechanical engineering, inspection technology/ camera travel drylin® E data sheet - Gearbox for stepper motors GEA-60-..._EN.pdf Planetary gears for igus® stepper motors NEMA 23, 23XL & 34 Increased motor torque Increased brake holding torque 2 installation sizes Reduction gearing of 3 & 5 available Typical applications:Packaging technology, general mechanical engineering, inspection technology/ camera travel

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Combination machine for thick and thin: The AMS 533 TWIN skinning machine is particularly suited to processing cuts with thick tendonsand skin, such as pork loin, pork silverside, beef or veal silverside and boiled beef fillet. Advantages Removal of tendons and skin with one machine TWIN transport rollers and specially coordinated blades providethe highest possible yields Ideal cutting width for powerful skinning and tendon removal inlarge and small cuts Effort-saving work table design due to ergonomicmachine assembly Blade guard in cleaning position Gear brake motor with quick stop Product-specific precision adjustment Options: Quick-clamp blade holder for tool-less blade changing Body lever switch Skinning procedure protection Skinning gloves Special tension rollers

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Our motors perform a wide variety of industrial drive tasks. Reliably and effectively. For example, our type Z cylindrical-rotor brake motors – also as brake motors – offer high drive efficiency – also in continuous duty. They are specially designed to match our gearbox range and provide for simple project engineering. Our conical-rotor brake motors with outputs of up to 55 kW are used for stopping-and-starting drives or for direct line-fed travel applications. Thanks to their unique brake principle, they are the first choice wherever demanding requirements have to be met by the brake.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Powerful derinding machine for large and small pieces of cheese. In addition to an ideal cutting width, the Weber Cheese Skinner offers product-specific height adjustment of the blade, meaning that natural and plastic rinds can be optimally removed. Maximum product yield is guaranteed. Advantages Powerful and with a compact footprint A special cheese transport roller and perfectly adjusted blades for optimal processing results Ideal cutting width for powerful derinding of large and small pieces of cheese Bolted blade with blade protection in cleaning position Unique geared brake motor with quick stop Options: special voltages

Request for a quote

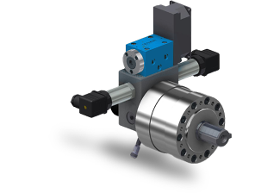

RK ROSE+KRIEGER GMBH

Germany

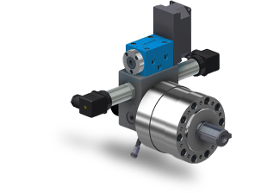

The completely equipped electrical cylinder unit includes the motor transmission unit, along with the motor brake, two-channel Hall-IC sensor and two end-limit switches. All connection lines run directly out of the unit to make configuration and initial start-up easier, particularly for PLC operation. The fixation of the electric cylinder connections is compatible with commercial pneumatic and hydraulic cylinders.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Assembly immediately upon receipt of order - generally in stock Category Compressed-air technology / Coupling heads and accessories for air brake systems / Duo-Matic / For motor vehicle Product number supplier 301860

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

One for many purposes: Powerful skinning machine for large and small cuts of beef, veal, pork, turkey, horse and game. The Skinner AMS 533 offers an ideal cutting width for processing large cuts, such as beef topside. Advantages Powerful for the highest yield from the smallest installation area Product-specific optional transport rollers and speciallycoordinated blades provide the highest possible yield Ideal cutting width for powerful skinning of large and small cuts Blade guard in cleaning position Gear brake motor with quick stop Product-specific tension rollers Newly-developed compressed air transport roller cleaning,resulting in consistent skinning results Options: Body lever switch Quick release lock for tool-free blade changes Special rollers Skinning procedure protection Special tension rollers

Request for a quote

J.D. NEUHAUS GMBH & CO. KG

Germany

JDN air hoists mini Carrying capacities: 125 kg, 250 kg, 500 kg, 980 kg Air pressure: 6 bar Standard Features interesting and inexpensive alternative even to hoists with other driving media suitable for lube-free operation suitable for application in hazardous areas (Explosion protection) few components only for easiest maintenance wear resistant motor braking system light weight for easy handling also suitable for horizontal pulling extremely sensitive lever control with emergency shut-off valve, max. control length 6 m available lifting heights: 3m, 5m, 8m with chain box as standard with manual trolley as option

Request for a quote

GSW SCHWABE AG

Germany

Strong plasmaburned back plate provides smooth and straight operation Removable and adjustable hub disk Fast and precise expansion via bevel gear with exceptionally wide ranges, allows clamping of all internationally common coil sizes From 1000 kg capacity equipped with lever type expansion Alternatively with guide rod coil fixation instead of expansion system (mainly for pallets) Pneumatic hold down arm Motorized pivoting Electropneumatic brake system Larger mandrel segments Traveling feature Different loading heights Various expansion ranges Different back plate sizes Loop control systems

Request for a quote

GSW SCHWABE AG

Germany

Effortless 180° rotation via foot pedal and automatic mechanical locking Optional sensory position readout Crank Expansion via directionally stable joints, easily operable even under weight Highestquality Reel Arbor with maintenancefree bearing and minimal deflection Sturdy and warp resistant body in welded construction for highest stability MHD Series PullOff Reel with manually adjustable brakes MHDM Series Payoff Reel with threephase motors for start / stop operation MHDR Series Payoff Reel with threephase motors and frequency inverter for continuous operation Optional Equipment MHDSeries Pneumatic hold down arms Electropneumatic brake systems Larger mandrel segments Motorized rotation Traveling feature w optional automatic centering Different mandrel heights Various expansion ranges Different back plate sizes Loop control systems...etc.

Request for a quote

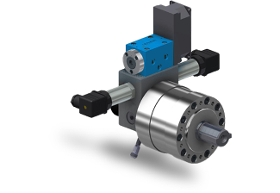

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for every challenge: Single-stage gear drive with hollow shaft — Gear Type: SN14H — Motor Type: Three-Phase (230/400V) and Direct Current (180/200V) — Ratios: 5; 7; 11; 15; 17; 20; 24; 30; 32; 38; 56; 75 — Motorpower AC: 45 - 120W / DC: 120-250W — Shaftdesign: Hollow Shaft — Max. permissible torques: 5,3-14 Nm — Effectiv torques: 0,6-14 Nm — Mounting: Gear Foot / Flange — Additional options: brake motors, UL/CSA-certification, thermal protection, encoder —Ratios Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for every challenge: The SN3VH-gearmotors impresses with its compact dimensions and flexible application range. The geared motors are available as three-phase or direct current versions and can be equipped with brakes or pulse generators (on request). SN3VH-gear types: SN3VH — Motor types: AC (230/400V) and DC (180/200V) — Shaft design: Ø14 Hollow shaft — Ratios: 5; 7; 11; 15; 17; 20; 24; 30; 32; 38; 56; 75 — Power: 120-250W — permissible torques: 11-17 Nm — effectiv torques: 3,2-23 Nm — Additional options: brake motors, UL/CSA-certification, thermal protection, encoder Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for every challenge: The SN3F gear series impresses with its compact dimensions and flexible application range. The flange-gear is available with solid shaft as well as with hollow shaft. The geared motors are available as three-phase or direct current versions and can be equipped with brakes or pulse generators (on request). SN3F-Gear types: SN3F / SN3FH / SN3FL / SN3FLH — Motor types: AC (230/400V) and DC (180/200V) — Shaft design: Solid (SN3F / SN3FL) or hollow shaft (SN3FH / SN3FLH) — Ratios: 5; 7; 11; 12; 15; 17; 20; 24; 30; 32; 38; 50; 56; 75 — Power: 120-250W — permissible torques: 11-17 Nm — effectiv torques: 3,2-23 Nm — Additional options: brake motors, UL/CSA-certification, thermal protection, encoder Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

RUHRGETRIEBE KG

Germany

The right drive solution for every challenge: The SN3B gear series is one of the most flexible and universally usable gear series form Ruhrgetriebe. The single stage gearboxes are available with a solid or hollow shaft - with or without flange. Available are different gear- and shaft positions and a large number of different motors. SN3B-Gear types: SN3B / SN3B4 / SN3BFH / SN3BH / SN3BHFL — Motor types: AC (230/400V) and DC (180/200V) — Shaft design: Solid (SN3B /SN3B4) or hollow shaft (SN3BFH /SN3BH / SN3BHFL) — Ratios: 5; 7; 11; 12; 15; 17; 20; 24; 30; 32; 38; 50; 56; 75 — Power: 120-250W — permissible torques: 11-17 Nm — effectiv torques: 3,2-23 Nm — Additional options: brake motors, UL/CSA-certification, thermal protection, encoder Additional Data: — Ball bearings for motor and gear — Worms hardened and ground — Wormwheel made of special bronze alloy For further information see product detail page.

Request for a quote

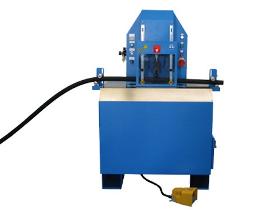

UNIFLEX-HYDRAULIK GMBH

Germany

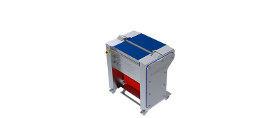

The small, light-weight cutting machine for workshops. 1-phase drive, 1.2 kW. For hydraulic hoses up to 1”. Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The EM 115 is a highly productive hose cutting machine. The machine is best suited for high volume manufacturing of 2" hoses along with workshop capability for 3" high pressure hose and 3" industrial hose. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 2”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The new 2" 4SH + SAE R 15 hose cutting machine for workshops (also as a 3" industrial machine available). Designed to perfection. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

For each type of workshop: This cutting machine with its 3 kW drive is also available as an ecoline or DC variant. For hydraulic hoses up to 1 ¼”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The safe high-quality cutting machine for the production process. All cutting blades are made of carefully tested material which ensures optimum cutting quality. 7.5 kW drive max. For hydraulic hose assemblies up to 3” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

This production cutting machine is available as a manual and as a pneumatic variant. Its cutting motors ensure optimum cutting results thanks to their unique minimum vibration. 4.6 kW drive. For hydraulic hose assemblies up to 2” and industrial hose assemblies up to 4”. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quoteResults for

Brake motors - Import exportNumber of results

44 ProductsCountries

Category

- Electric motors and parts (10)

- Cutting - machine tools (6)

- Brakes, servo-brakes and accessories (5)

- Moto-reducers (4)

- Electric transformers, converters and rectifiers (2)

- Meat processing machines (2)

- Metal industrial presses (2)

- Metal straightening machines (2)

- Hoists and winches (1)

- Construction - Machines & Equipment (1)

- Cranes and gantries (1)

- Food Industry - Machines & Equipment (1)

- Goods handling systems, continuous (1)

- Hydraulic equipment (1)

- Packing and packaging - machinery and equipment (1)